Manufacturing method of oled panel, temporary pairing structure

A manufacturing method and panel technology, applied in the field of OLED manufacturing, can solve problems such as inability to meet demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] As mentioned in the background art, the magnetic adsorption method is only applicable to metal shadow masks. For shadow masks made of other materials (such as non-metallic materials), the existing magnetic adsorption method cannot meet the demand.

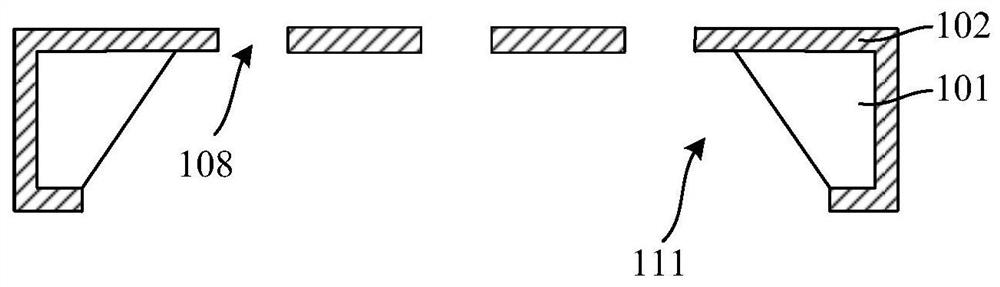

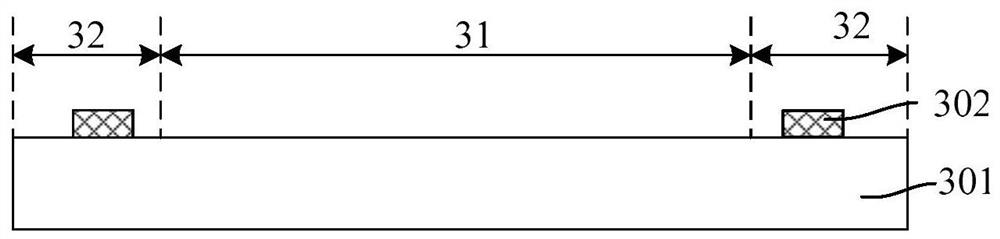

[0043] To this end, the present invention provides a method for manufacturing an OLED panel and a temporary pairing structure, wherein the method for manufacturing an OLED panel comprises sequentially combining the substrate with the first vapor deposition shadow mask, the second vapor deposition shadow mask or the third vapor deposition shadow mask. When the shadow mask is bonded and debonded three times, each bonding only requires the substrate on the outside of one of the corresponding bank structures (the first bank structure, the second bank structure or the third bank structure) UV glue is formed between the corresponding evaporation shadow masks, specifically when bonding for the first time (when forming the first ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com