Multi-color overprinted tipping paper with metallic luster and preparation method thereof

A technology of metallic luster and tipping paper, applied in papermaking, paper coating, household appliances, etc., can solve problems such as monotonous color, increased production cost, and poor solvent release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

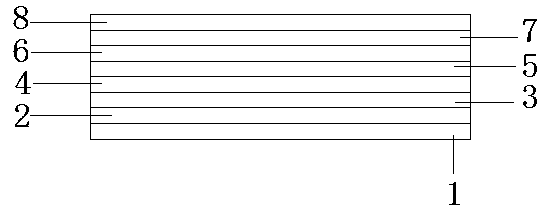

[0047] A multi-color overprint tipping paper with metallic luster, comprising an aluminized tipping base paper layer, an ink layer and a varnish layer 8, the aluminized tipping base paper layer sequentially includes an anti-curling layer 1, a tipping white base paper Layer 2, composite adhesive layer 3, aluminum plating layer 4 and peeling protective layer 5, said ink layer includes base color transparent ink layer 6 and overprint ink layer 7; base color transparent ink layer 6, overprint ink layer 7 and varnish layer 8 in sequence Printed on the release protection layer 5.

[0048] Implement the following technical solutions:

[0049] (1) The printing base material is 45g / m2 2 aluminized tipping paper base paper;

[0050] (2) Base color transparent ink, the specific formula is calculated in parts by weight: 10 parts of aldehyde and ketone resin, 7 parts of vinyl acetate resin, 3 parts of rosin pentaerythritol ester, 15 parts of cellulose acetate butyrate, 5 parts of transpa...

Embodiment 2

[0074] A multi-color overprint tipping paper with metallic luster is implemented according to the following technical scheme:

[0075] (1) The printing base material is 36g / m2 2 aluminized tipping paper base paper;

[0076] (2) Base color transparent ink, the specific formula is calculated in parts by weight: 13 parts of aldehyde and ketone resin, 5 parts of vinyl acetate resin, 4 parts of rosin pentaerythritol ester, 13 parts of cellulose acetate butyrate, 6 parts of transparent pigment yellow, micro 3 parts of crystal wax, 26.5 parts of ethanol, 26.5 parts of ethyl acetate;

[0077] (3) One-color overprint ink, the specific formula is calculated in parts by weight: 13 parts of polyvinyl butyral, 17 parts of cellulose acetate butyrate, 4 parts of pigment red, 3 parts of microcrystalline wax, 63 parts of ethanol; Overprinting ink, the specific formula is calculated in parts by weight: 13 parts of polyvinyl butyral, 17 parts of cellulose acetate butyrate, 4 parts of pigment b...

Embodiment 3

[0081] A multi-color overprint tipping paper with metallic luster is implemented according to the following technical scheme:

[0082] (1) The printing base material is 32g / m 2 aluminized tipping paper base paper;

[0083] (2) Base color transparent ink, the specific formula is calculated in parts by weight: 15 parts of aldehyde and ketone resin, 8 parts of vinyl acetate resin, 5 parts of rosin pentaerythritol ester, 10 parts of cellulose acetate butyrate, 8 parts of transparent pigment yellow, micro 4 parts of crystal wax, 25 parts of ethanol, 25 parts of ethyl acetate;

[0084] (3) One-color overprint ink, the specific formula is calculated in parts by weight: 15 parts of polyvinyl butyral, 15 parts of cellulose acetate butyrate, 5 parts of pigment red, 4 parts of microcrystalline wax, 61 parts of ethanol; Overprinting ink, the specific formula is calculated in parts by weight: 15 parts of polyvinyl butyral, 15 parts of cellulose acetate butyrate, 5 parts of pigment brown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com