A kind of preparation method of polyimide fiber filament

A technology of polyimide fiber and filament, which is applied in the field of preparation of polyimide fiber filament, and can solve the problem of large fluctuations in elongation at break and breaking strength of finished fiber, low strength of polyimide fiber, and affecting performance and application issues, to achieve the effects of high product strength and elongation at break, improved fiber strength and uniform quality, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

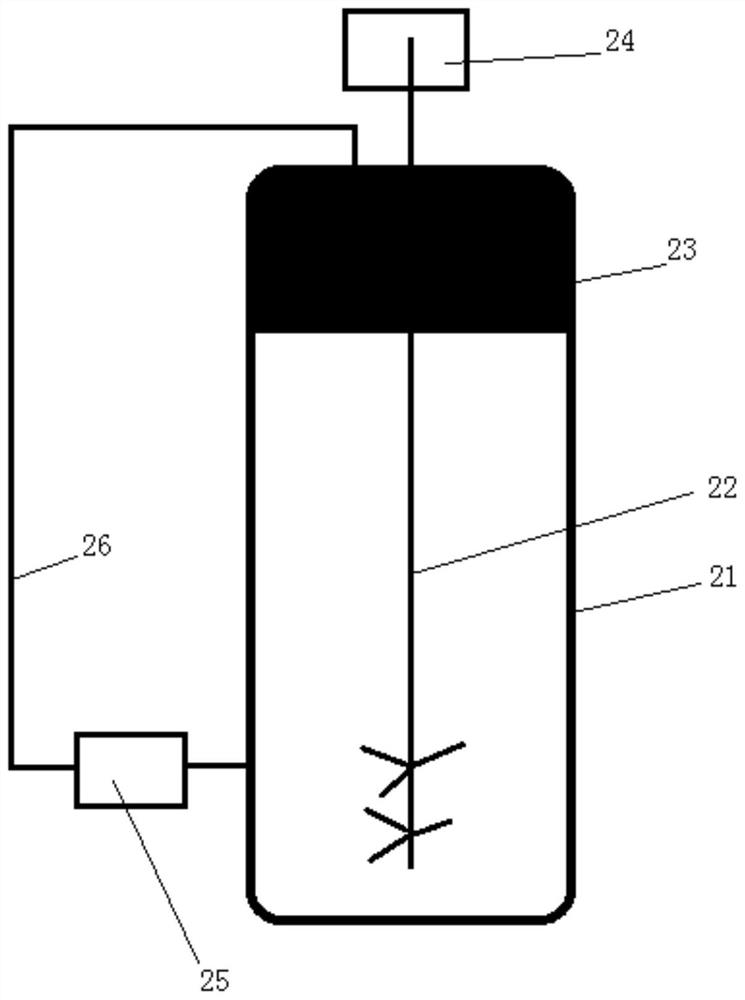

[0029] A kind of preparation method of polyimide fiber filament (technical process is as image 3 As shown), after the polyamic acid solution is prepared by polymerization, it is left to stand in vacuum for 24 hours, and then continues to defoam through a special vacuum cycle. Dry spinning is carried out after being filtered by a special filter element. The solvent is precipitated and brought out by high-temperature nitrogen heating, and is recovered after cooling. The nitrogen pressure used for solvent recovery in the spinning tunnel is 0.3Mpa, and the temperature is 150°C. It is recycled and used in nitrogen. The oxygen content is 0.3%, and the spinning speed is 1500m / min; then the fiber filaments are subjected to polar imidization and stretching treatment by hot rollers such as GR1, GR2, GR3, GR4, GR5, GR6, etc., TGR1 is 162 ° C, TGR2 is 230 ℃, TGR3 is 290, the stretch ratio DR1 between GR1 and GR2 is 1.05, the stretch ratio DR2 between GR2 and GR3 is 1.15, TGR4 is 380°C, T...

Embodiment 2

[0031] A kind of preparation method of polyimide fiber filament (technical process is as image 3As shown), after the polyamic acid solution was prepared by polymerization, it was left to stand in vacuum for 48 hours, and then continued to defoam through a special vacuum cycle. Dry spinning is carried out after being filtered by a special filter element. The solvent is precipitated and brought out by high-temperature nitrogen heating, and is recovered after cooling. The nitrogen pressure used for solvent recovery in the spinning shaft is 0.5Mpa, and the temperature is 250°C. It is recycled and used in nitrogen. The oxygen content is 4.2%, and the spinning speed is 50m / min; then the fiber filaments are subjected to polar imidization and stretching treatment by hot rollers such as GR1, GR2, GR3, GR4, GR5, GR6, etc., TGR1 is 220 ° C, TGR2 is 280 ℃, TGR3 is 350, the stretch ratio DR1 between GR1 and GR2 is 1.10, the stretch ratio DR2 between GR2 and GR3 is 1.20, TGR4 is 420°C, TGR...

Embodiment 3

[0033] A kind of preparation method of polyimide fiber filament (technical process is as image 3 As shown), after the polyamic acid solution was prepared by polymerization, it was left to stand in vacuum for 30 hours, and then continued to defoam through a special vacuum cycle. Dry spinning is carried out after being filtered by a special filter element, and the solvent is precipitated and taken out by heating with high-temperature nitrogen, and recovered after cooling. The nitrogen pressure used for solvent recovery in the spinning tunnel is 0.4Mpa, and the temperature is 220°C. It is recycled and used in nitrogen. The oxygen content is 3.5%, and the spinning speed is 800m / min; then the fiber filaments are subjected to polar imidization and stretching treatment by hot rollers such as GR1, GR2, GR3, GR4, GR5, GR6, etc., TGR1 is 190 ° C, TGR2 is 240 ℃, TGR3 is 320, the stretching ratio DR1 between GR1 and GR2 is 1.07, the stretching ratio DR2 between GR2 and GR3 is 1.16, TGR4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com