Novel rotary magnetic control circular column arc target device

A magnetically controlled, circular technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of affecting the magnetic field strength, easy arcing, waste of raw materials, etc., to improve the quality of film formation and reduce Effects of using cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

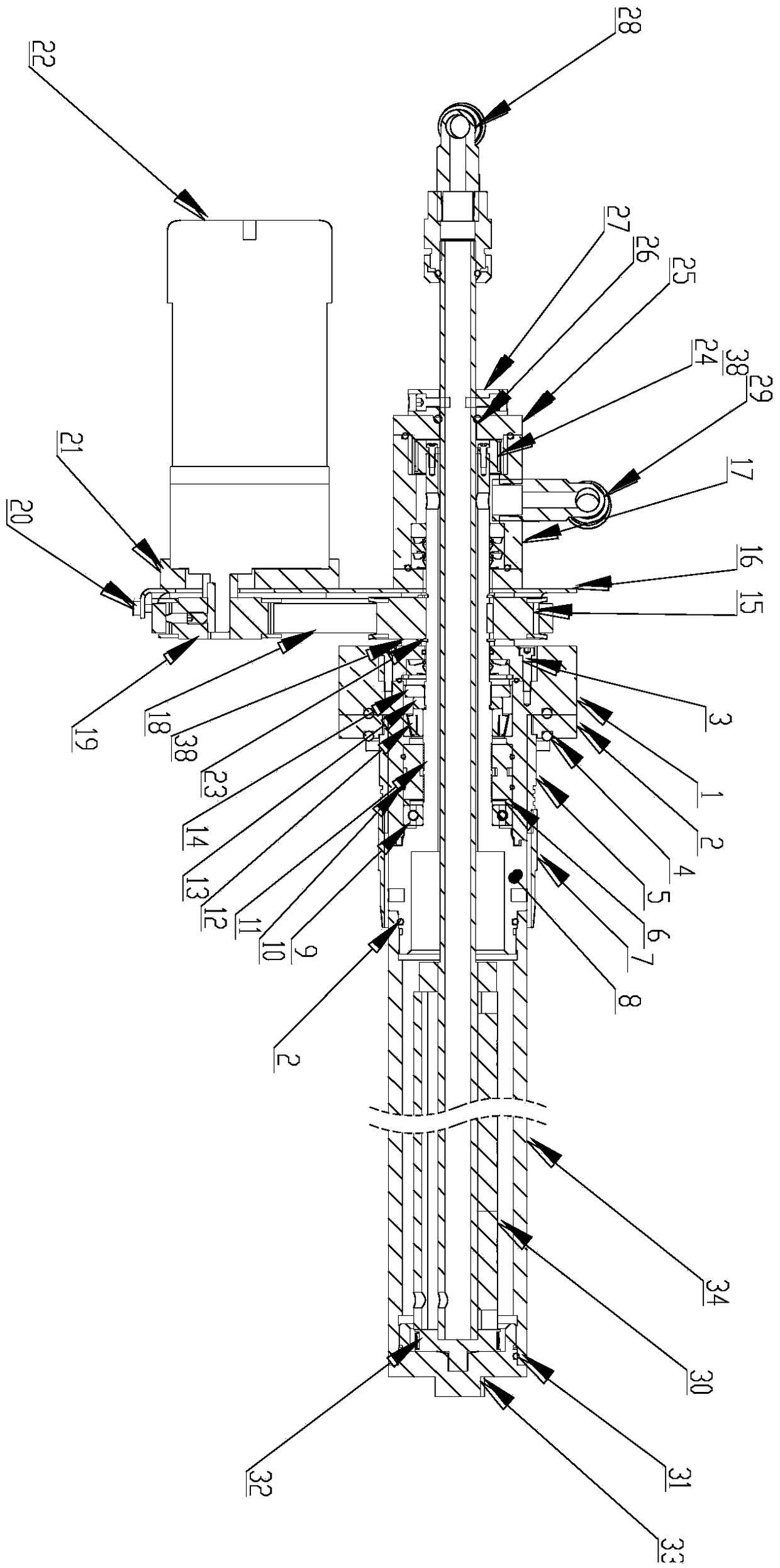

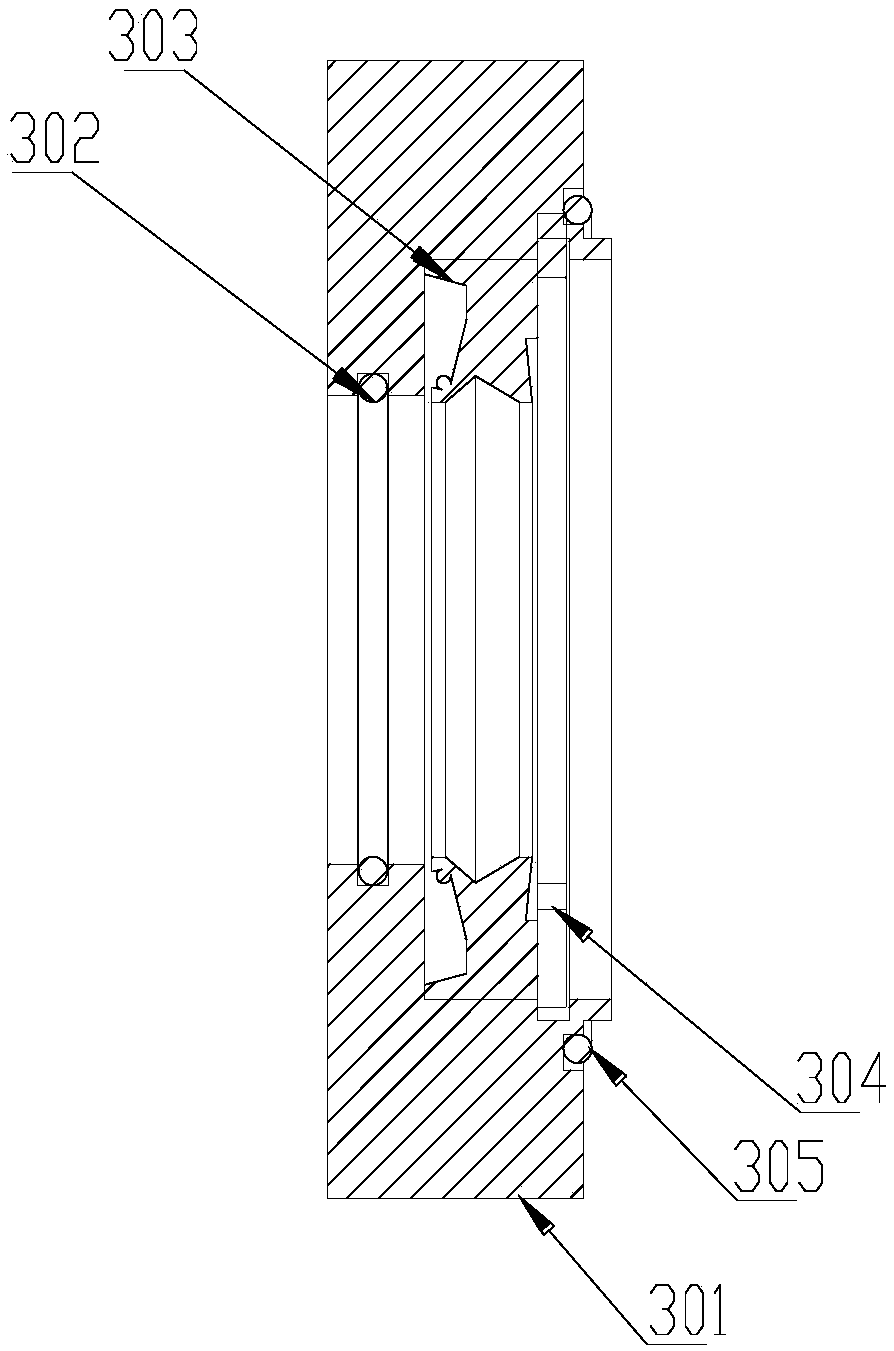

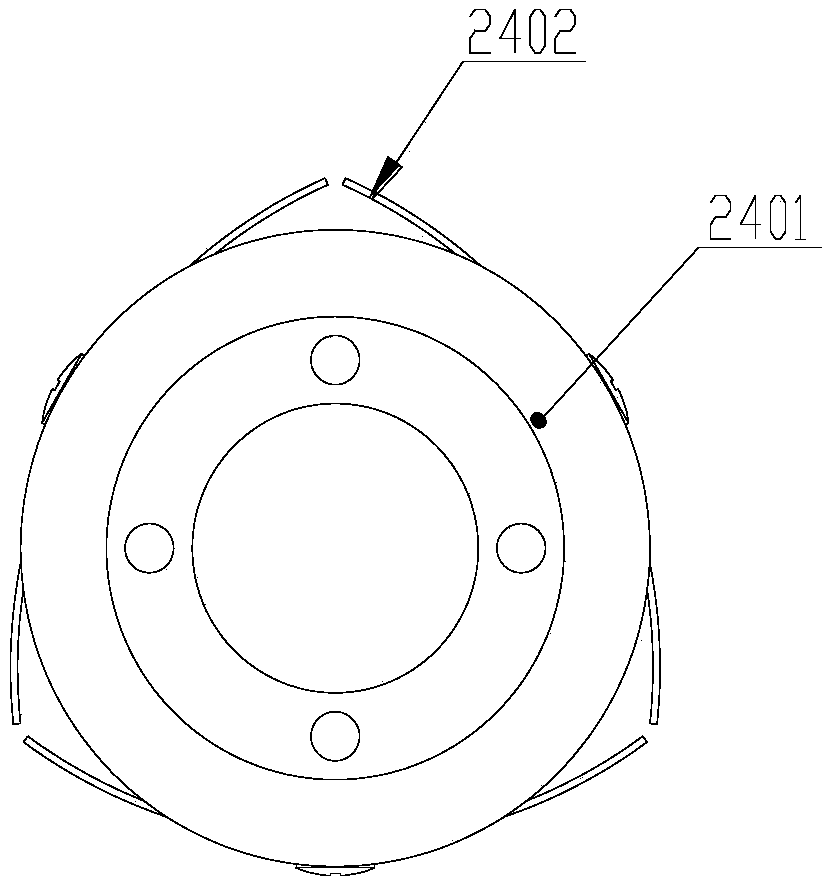

[0029] refer to Figure 1-Figure 6, the specific embodiment adopts the following technical solutions: a new type of rotating magnetron cylindrical arc target device, including a housing 1, a first insulating pad 2, a vacuum sealing end cap device 3, a first O-ring 4, a shielding cover Insulation pad 5, shaft core retaining ring 6, shielding cover 7, drive shaft core 8, self-aligning bearing 9, magnetic sealing device 10, magnetic fluid 11, tapered roller bearing 12, small round nut 13, lock nut 14, drive Timing pulley 15, motor bracket 16, water diversion device 17, timing belt 18, motor timing pulley 19, motor tensioning device 20, motor insulating pad 21, drive motor 22, shaft circlip 23, first rotating conductive device 24. First end sealing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com