Filtration and clarification process for baijiu

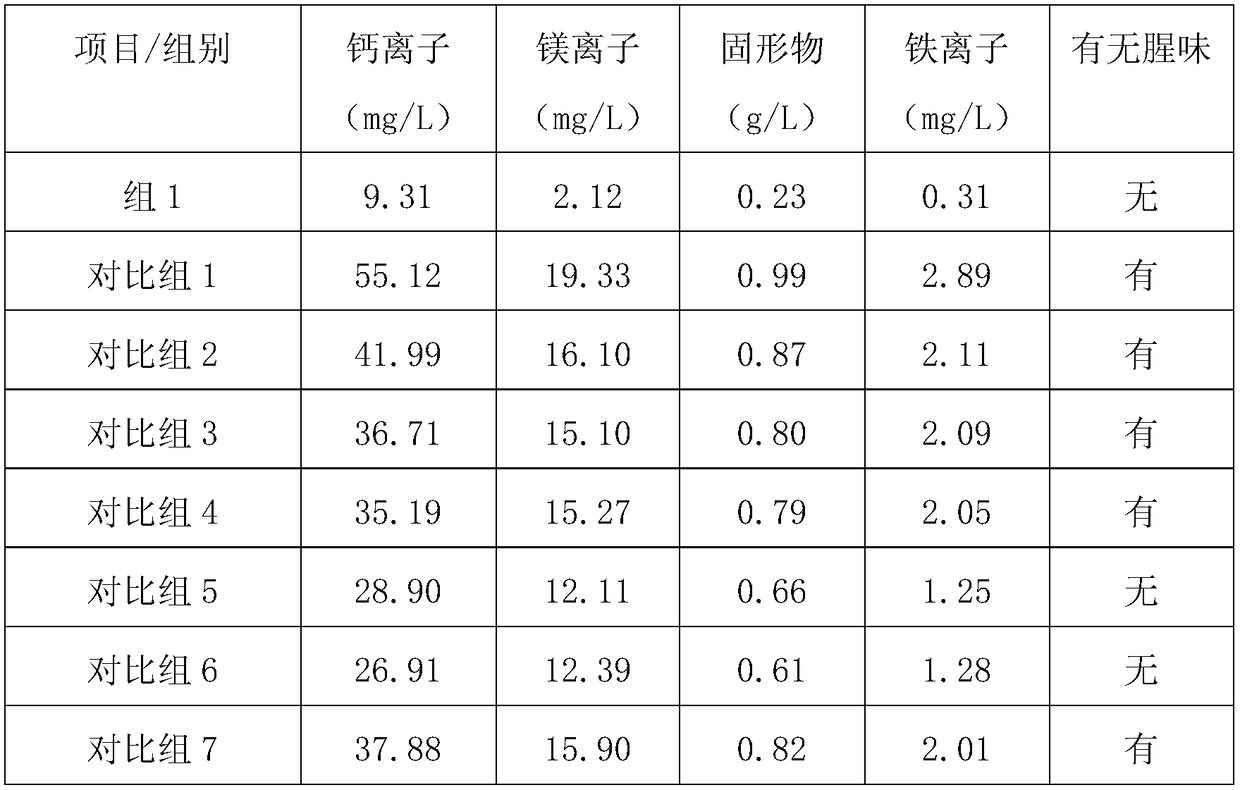

A liquor and technology technology, applied in the field of liquor processing, can solve the problems of alcohol smell, not suitable for clarification of Debao liquor, solid content exceeding the standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of filtration and clarification process of liquor of the present embodiment comprises the following steps:

[0020] (1) Coarse filtration: add 0.5g / L diatomaceous earth to the liquor, stir for 20min, let stand at 5°C for 5 days, centrifuge at 2000r / min for 15min, remove the precipitate, take the supernatant, and obtain the coarsely filtered liquor ;

[0021] (2) Fine filtration: add 0.05g / L chitosan solution to the above-mentioned coarse filter wine, mix and stir evenly, after ultrasonic treatment at 200W for 20min, add 1g / L active adsorbent, stir for 30min, at 5°C Let it stand for 3 days, centrifuge at 2000r / min for 15min, remove the precipitate, and filter the upper liquor with a microporous membrane with a pore size of 0.1μm.

[0022] The preparation method of the chitosan solution is as follows: add chitosan into a citric acid solution with a mass concentration of 1% and heat until dissolved, the mass ratio of chitosan to the citric acid solution is 1:100, a...

Embodiment 2

[0025] A kind of filtration and clarification process of liquor of the present embodiment comprises the following steps:

[0026] (1) Coarse filtration: add 1.8g / L diatomaceous earth to the liquor, stir for 50min, let stand at 10°C for 7 days, centrifuge at 2500r / min for 25min, remove the precipitate, take the supernatant, and obtain the coarsely filtered liquor ;

[0027] (2) Fine filtration: add 0.15g / L chitosan solution to the above-mentioned coarse filter wine and mix well, after ultrasonic treatment at 300W for 30min, add 3g / L active adsorbent, stir for 50min, and then filter the mixture at 8°C Let it stand for 5 days, centrifuge at 2500r / min for 25min, remove the precipitate, and filter the upper liquor with a microporous membrane with a pore size of 0.3μm.

[0028] The preparation method of the chitosan solution is as follows: add chitosan into a citric acid solution with a mass concentration of 2% and heat until dissolved, the mass ratio of chitosan to the citric acid...

Embodiment 3

[0031] A kind of filtration and clarification process of liquor of the present embodiment comprises the following steps:

[0032] (1) Coarse filtration: add 1.5g / L diatomaceous earth to liquor, stir for 30min, let it stand at 8°C for 6 days, centrifuge at 2200r / min for 20min, remove the precipitate, take the supernatant, and obtain coarse filtration liquor ;

[0033] (2) Fine filtration: add 0.10g / L chitosan solution to the above-mentioned coarse filter wine, mix and stir evenly, after ultrasonic treatment at 250W for 25min, add 2g / L active adsorbent, stir for 40min, and place at 7°C Let it stand for 4 days, centrifuge at 2300r / min for 18min, remove the precipitate, and filter the upper liquor with a microporous membrane with a pore size of 0.2μm.

[0034] The preparation method of the chitosan solution is as follows: add chitosan into a citric acid solution with a mass concentration of 1.5% and heat until dissolved, the mass ratio of chitosan to citric acid solution is 1.5:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com