A kind of ultra-fine sticky-peeling force acrylic pressure-sensitive adhesive and preparation method thereof

An acrylic pressure-sensitive adhesive, peel force technology, applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc., can solve unstable, expensive silicone pressure-sensitive adhesive, plasticizer contamination to be attached and other problems to achieve the effect of stable peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

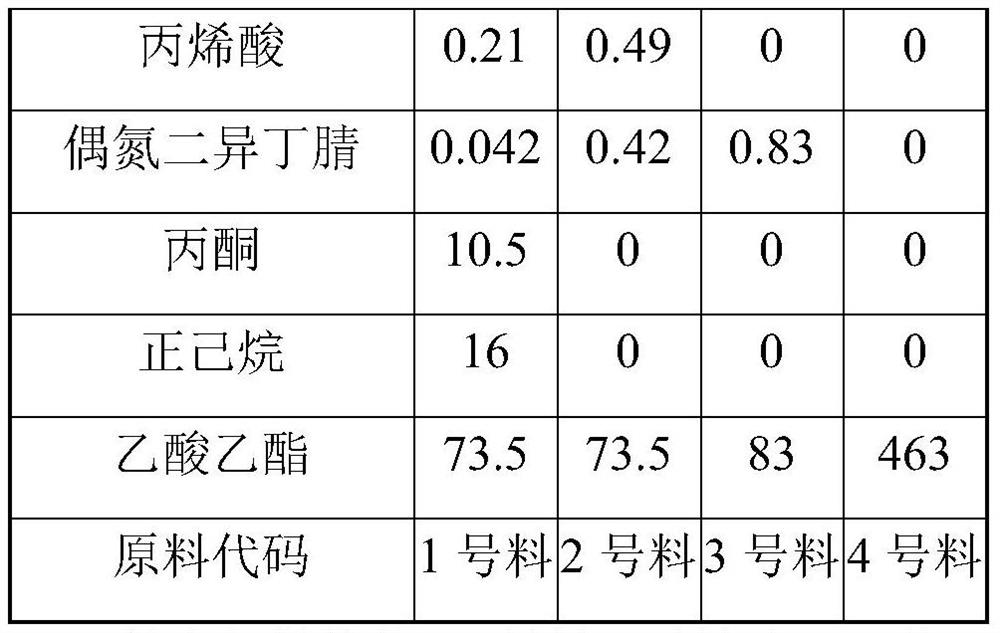

[0026] The additives and the amount added in the preparation process (in "grams"):

[0027] raw material code No. 1 material No. 2 material No. 3 material No. 4 material Isooctyl Acrylate 71.19 166.11 0 0 octadecyl acrylate 8.4 19.6 0 0 Hydroxyethyl acrylate 4.2 9.8 0 0 acrylic acid 0.21 0.49 0 0 Azobisisobutyronitrile 0.042 0.42 0.83 0 acetone 66 66 0 0 Toluene 33 33 83 0 Ethyl acetate 438.54

[0028] In this example, 30% of all monomers (Material No. 1) 2-ethylhexyl acrylate, octadecyl acrylate, hydroxyethyl acrylate, acrylic acid, initiator and solvent were put into the reaction kettle according to the formula , and reacted at 68°C for 20min to obtain a prepolymer; then the remaining raw materials were added dropwise at a uniform speed within 90min, and the reaction was controlled at 70°C. After the dropwise addition, the temperature was kept for 60 min to further increase the po...

Embodiment 2

[0031] The additives and the amount added in the preparation process (in "grams"):

[0032]

[0033]

[0034] In this example, 30% of all monomers (Material No. 1) 2-ethylhexyl acrylate, octadecyl acrylate, hydroxyethyl acrylate, acrylic acid, initiator and solvent were put into the reaction kettle according to the formula , and reacted at 68°C for 30min to obtain a prepolymer; then the remaining raw materials were added dropwise at a uniform speed within 90min, and the reaction was controlled at 70°C. After the dropwise addition, the temperature was continued for 60min to further increase the polymer chain, and the water bath was set at a temperature of 80°C. After the heat preservation, the No. 3 material was mixed uniformly and slowly added dropwise into the reaction device, and the dropping time was controlled at 60min and a temperature of 70°C; After the material No. 3 is added dropwise, it is also stirred and kept for 90 minutes; after the insulation, the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com