Gypsum-based putty powder capable of inducing negative ions

A gypsum-based and putty powder technology is applied in the field of putty powder and gypsum-based putty powder, and can solve the problems of restricting the popularization and use of putty powder, being expensive, and not having an industrial scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In addition, the putty powder of the embodiment of the present invention can be prepared by the following method:

[0058] Pre-mix the admixture, compatible material, and functional material; then add them to the base material and mix again; mix until uniform, and then get the gypsum-based putty powder that can induce negative ions.

[0059] Specifically, it can be:

[0060] The components are weighed according to the corresponding mass percentages, and each component and its corresponding mass percentages are as described above;

[0061] Add the compatible material and functional material to the admixture in turn, and mix;

[0062] Then add it to the base material and mix again;

[0063] Mix to a uniform state to obtain a gypsum-based putty powder that can induce negative ions.

[0064] The gypsum-based putty powder that can induce negative ions in the embodiment of the present invention fully complies with national environmental protection, radionuclide limit relat...

Embodiment 1

[0069] 86 kg of construction gypsum, 1.5 kg of ferrite powder, 2 kg of Chinese medical stone powder, 3 kg of talcum powder, 3 kg of quartz sand, 3.1 kg of rectorite powder, 1.15 kg of brucite fiber, 0.02 kg of collagen protein, 0.08 kg of carboxylate Methyl starch, 0.15 kg polycarboxylate superplasticizer.

[0070] Among them, the construction gypsum is S-type hemihydrate gypsum, the iron magnesium tourmaline powder is 2500 mesh, the Chinese medical stone powder is 2500 mesh, the talc powder is 325 mesh, the quartz sand is 600 mesh, the rectorite powder is 1250 mesh, and the natural mineral fiber is For brucite fiber, the protein content in collagen is 95% and the average molecular weight is 1000Da. When carboxymethyl starch is formulated into a 2% aqueous solution, the viscosity is 800mPa·s (25°C).

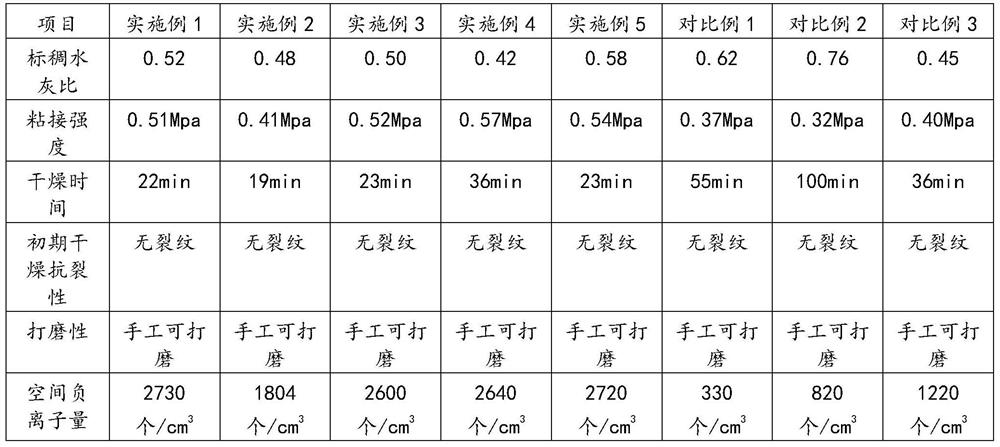

[0071] The performance test results are shown in Table 1.

Embodiment 2

[0073] 86 kg of construction gypsum, 1 kg of iron-magnesite tourmaline powder, 3.5 kg of Chinese medical stone powder, 2 kg of talc powder, 4 kg of quartz sand, 1.85 kg of rectorite powder, 1.35 kg of brucite fiber, 0.03 kg of collagen, 0.02 kg of carboxylate Methyl starch, 0.25 kg polycarboxylate superplasticizer.

[0074] Among them, the construction gypsum is S-type hemihydrate gypsum, the iron magnesium tourmaline powder is 5000 mesh, the Chinese medical stone powder is 5000 mesh, the talcum powder is 325 mesh, the quartz sand is 1000 mesh, the rectorite powder is 1000 mesh, and the natural mineral fiber is For brucite fiber, the protein content of bone collagen is 85% and the average molecular weight is 2000Da. When carboxymethyl starch is formulated into a 2% aqueous solution, the viscosity is 1200mPa·s (25°C).

[0075] Others are the same as embodiment 1.

[0076] The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com