A kind of high-strength phenolic hollow microsphere and preparation method thereof

A hollow microsphere, high-strength technology, applied in the field of hollow microspheres prepared by spray drying, can solve the problems of reduced density, low compressive strength, impact, etc., and achieve the effect of improving compressive strength and avoiding thermal oxygen aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

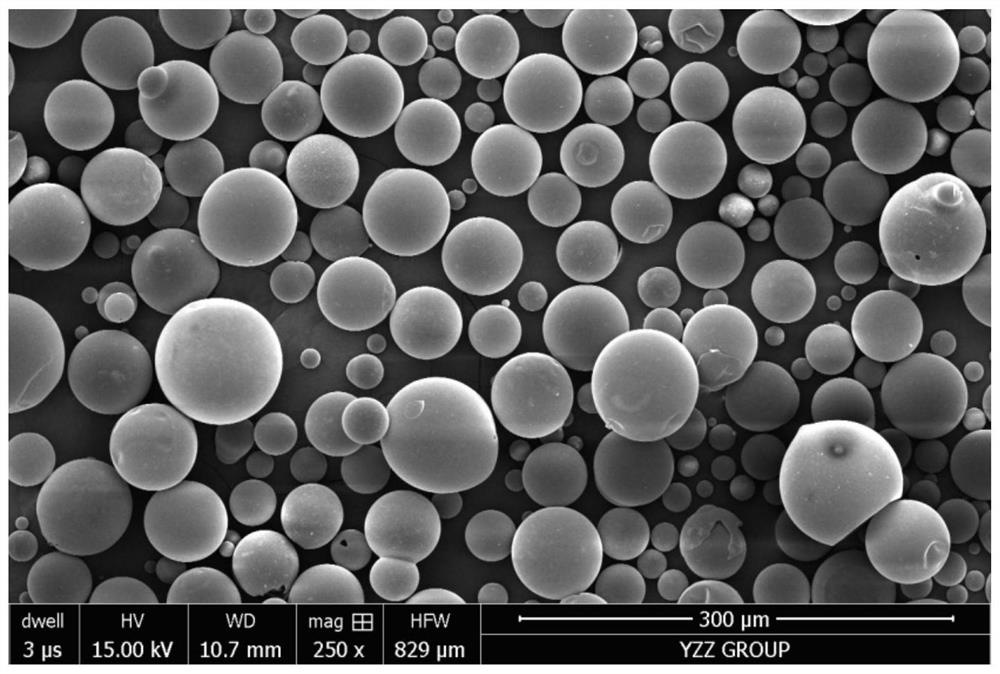

[0018] According to the ratio of phenolic resin:foaming agent:surfactant=100:1:2 (weight ratio), the above components are fully stirred evenly to obtain the resin material for spray drying. Wherein the foaming agent is foaming agent H, and the surfactant is BD3088 (a silicone surfactant). Then the material is input into the centrifugal atomizer at a constant speed, and nitrogen is used as the dry air flow to carry out spray drying in a closed spray drying tower to obtain phenolic hollow microspheres. Control the air inlet temperature of the closed spray drying equipment to 280°C. The particle density of the product obtained by adopting this process and formula is 0.32g / cm 3 ; Broken ball rate is 4.1%; accumulation coefficient is 50%; breakage rate is 52% under 2MPa pressure. The prepared phenolic hollow microspheres are as attached figure 1 As shown in the SEM photos, the particle size is less than 300 microns, the roundness is regular and there are few broken balls.

Embodiment 2

[0020] According to the ratio of phenolic resin:foaming agent:surfactant=100:3:3 (weight ratio), the above components are fully stirred evenly to obtain the resin material for spray drying. Wherein the foaming agent is foaming agent AC, and the surfactant is sodium lauryl sulfate. Then the material is input into the centrifugal atomizer at a constant speed, and nitrogen is used as the dry air flow to carry out spray drying in a closed spray drying tower to obtain phenolic hollow microspheres. Control the air inlet temperature of the closed spray drying equipment to be 300°C. The particle density of the product obtained by adopting this process and formula is 0.27g / cm 3 ; Broken ball rate is 5.5%; accumulation coefficient is 51%; breakage rate is 57% under 2MPa pressure.

Embodiment 3

[0022] According to the ratio of phenolic resin:foaming agent:surfactant=100:0.5:1.5 (weight ratio), the above components are fully stirred evenly to obtain the resin material for spray drying. Wherein the foaming agent is foaming agent H, and the surfactant is Tween 80. Then the material is input into the centrifugal atomizer at a constant speed, and nitrogen is used as the dry air flow to carry out spray drying in a closed spray drying tower to obtain phenolic hollow microspheres. Control the air inlet temperature of the closed spray drying equipment to be 320°C. The particle density of the product obtained by adopting this process and formula is 0.38g / cm 3 ; Broken ball rate is 4.5%; accumulation coefficient is 54%; breakage rate is 50% under 2MPa pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com