Cutting method of slicing machine with two spindles instead of three spindles

A cutting method and slicer technology, applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of large wire consumption, consumption, and high cost ratio of diamond wire, so as to reduce the number of bending times and reduce the breakage The effect of line risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

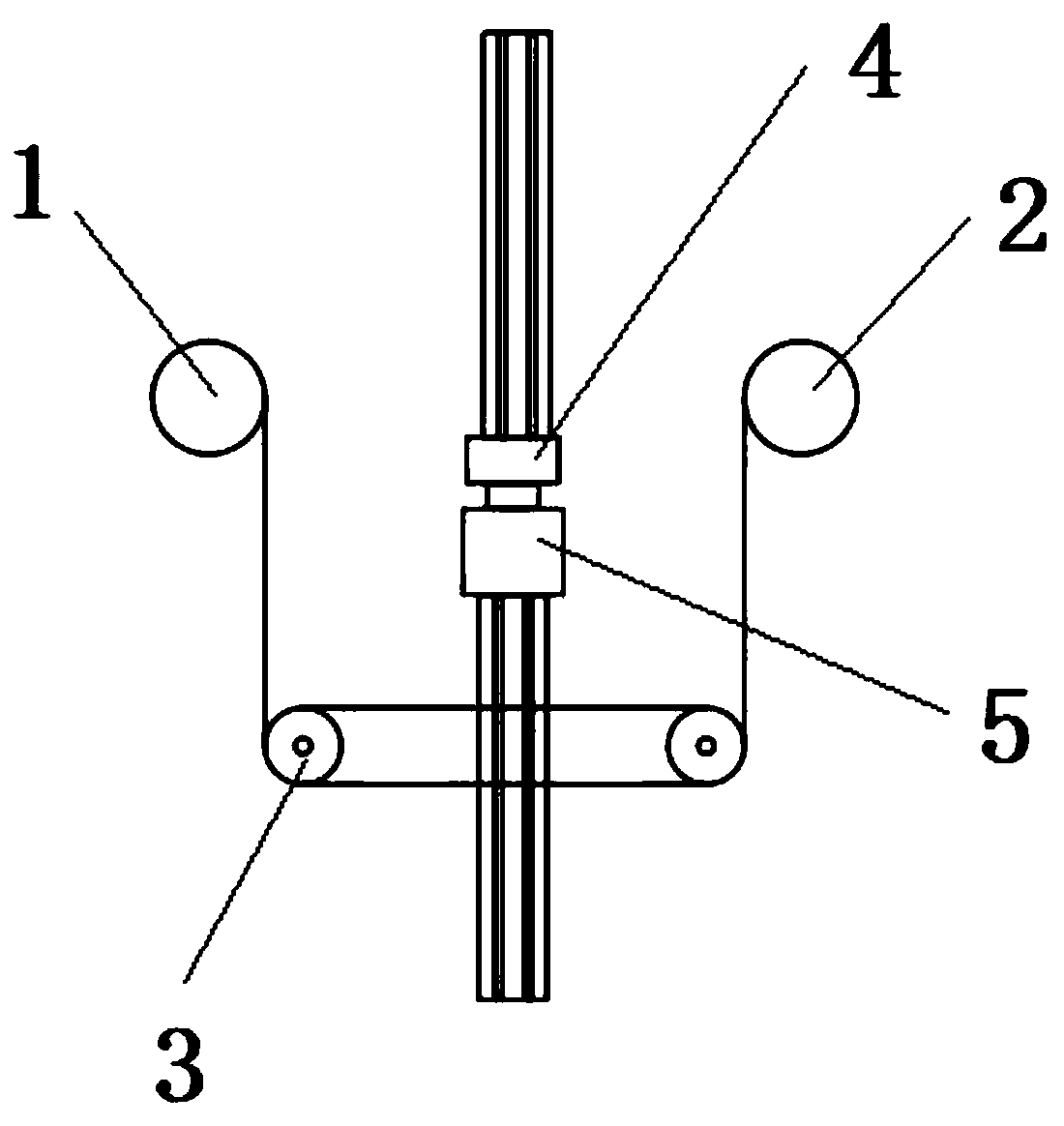

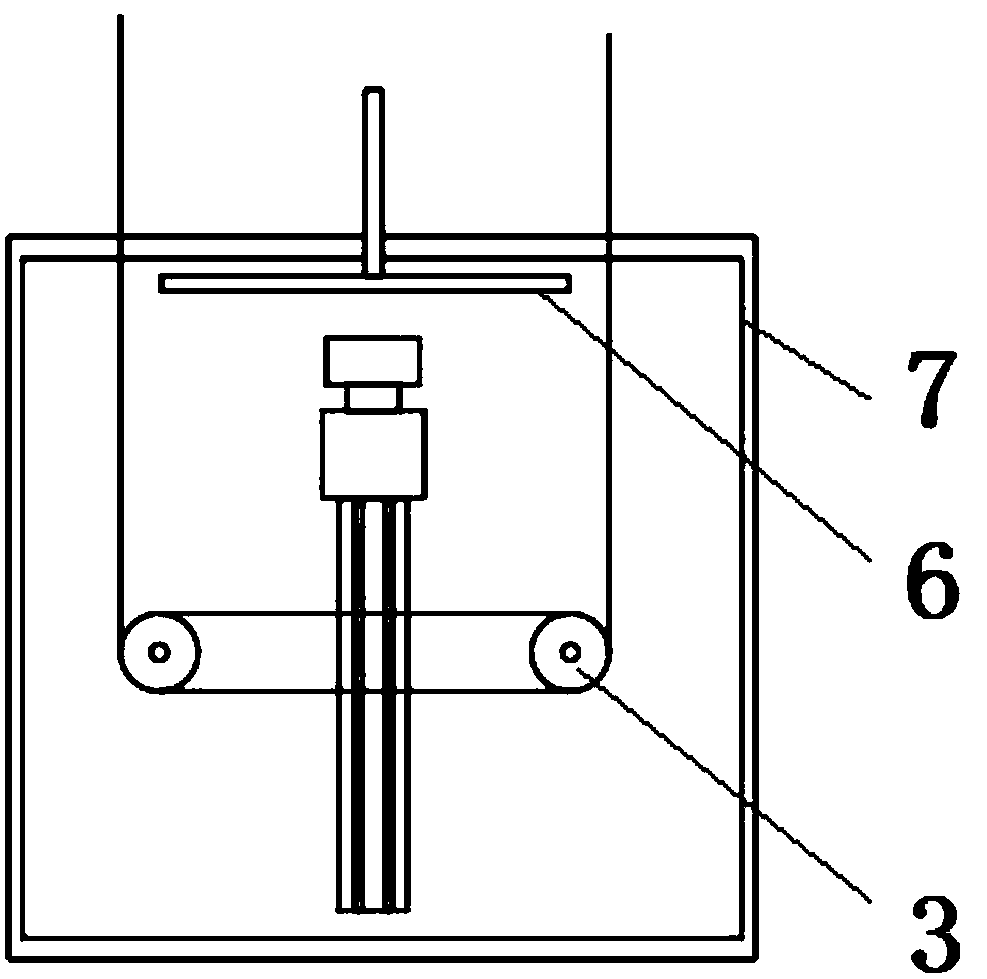

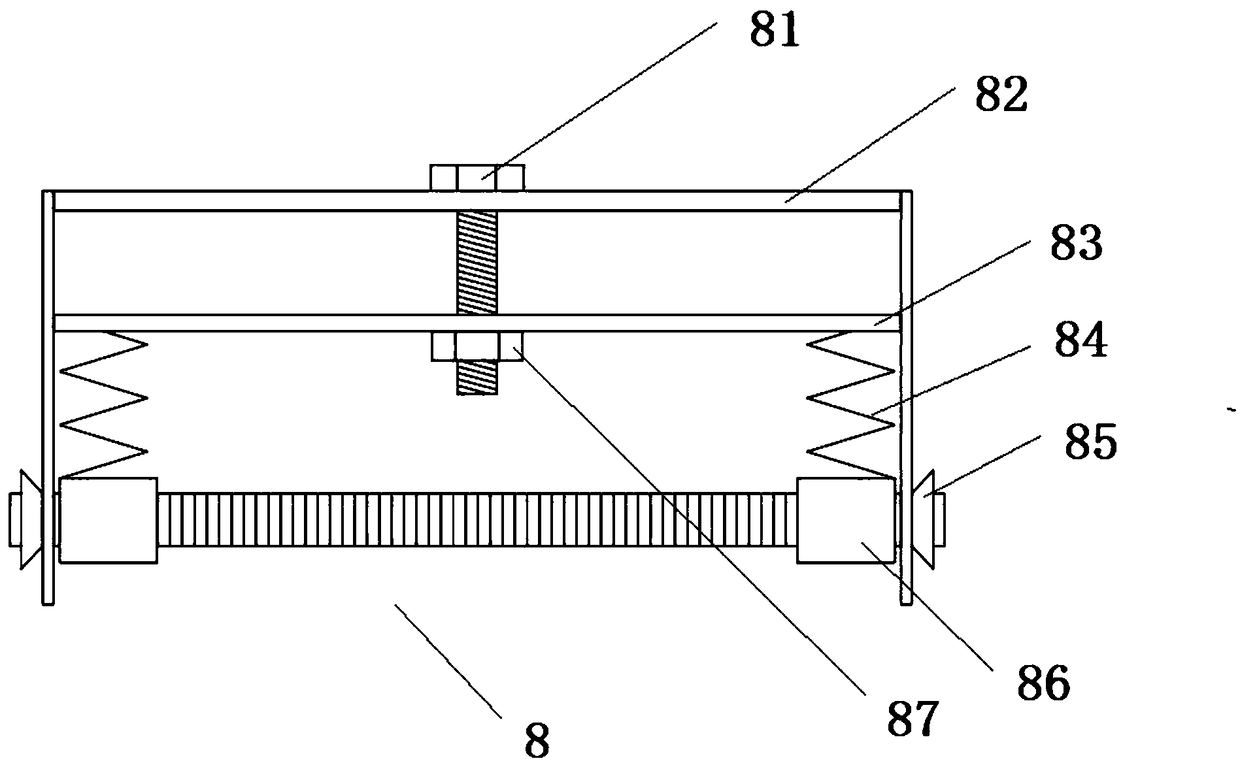

[0046] see Figure 1 to Figure 2 , a three-axis to two-axis slicer cutting method, comprising the following steps: Step 1, winding the diamond wire on the slicer; the slicer includes a driving mechanism for driving the movement of the gold wire, and the driving mechanism includes a pay-off roller 1. Two parallel spindles 3 and take-up roller 2, the diamond wire passes through the pay-off roller 1, the two spindles 3 and the take-up roller 2 in sequence, and the two ends of the diamond wire are respectively fixed with the pay-off roller 1 and the take-up roller 2. The part of the diamond wire wound on the two spindles 3 constitutes a wire mesh for cutting silicon ingots. The length of the wire mesh is 3.6km-4km; step 2, clamping and fixing the silicon ingots on a silicon ingot holder On the holding mechanism 5, the silicon ingot holding mechanism 5 is installed on a ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com