Preparation method and application of Ag2MoO4 catalytic composite

A composite material and a certain amount of technology, applied in the field of photocatalytic materials and nanomaterials, can solve problems such as reducing the lifespan of red blood cells, the ability to transport oxygen, and changing the shape of red blood cells, achieving the effects of short reaction time, uniform particles, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a kind of Ag 2 MoO 4 The preparation method (x=0.5) of the visible light catalytic composite material comprises the following steps.

[0036] Step 1. Add the mixture of 3mmol ammonium tungstate and 30mmol trimethylammonium bromide (CTAB) into 30ml deionized water, ultrasonically disperse the solution for about 10min, and pour the solution into the flask at the lower end of the Soxhlet extractor, Stir for 30 minutes, and control the temperature of the oil zone at 60°C to obtain solution A.

[0037] Step 2. Weigh a certain amount of nitric acid solution, dissolve it in 30ml of ethanol / water solution, the volume ratio of ethanol to deionized water is 1:10, control the pH of the solution to 5, stir until completely mixed, and obtain solution B.

[0038] Step 3. Slowly pour solution B into solution A, stir for 10 hours, filter the resulting suspension with suction, wash with 100ml of deionized water for 3 times, and dry at 60°C for 8 hours to obtain powder C; put powder C ...

Embodiment 2

[0043] a kind of Ag 2 MoO 4 The preparation method (x=0.1) of the visible light catalytic composite material comprises the following steps.

[0044] Step 1. Add the mixture of 2mmol ammonium tungstate and 20mmol trimethylammonium bromide (CTAB) into 20ml deionized water, ultrasonically disperse the solution for about 15min, and pour the solution into the flask at the lower end of the Soxhlet extractor. Stir for 60 minutes, and control the temperature of the oil domain at 70°C to obtain solution A.

[0045] Step 2. Weigh a certain amount of nitric acid solution, dissolve it in 30ml of ethanol / water solution, the volume ratio of ethanol to deionized water is 1:10, control the pH of the solution to 3.5, stir until completely mixed, and obtain solution B.

[0046] Step 3. Slowly pour solution B into solution A, stir for 10 hours, filter the resulting suspension with suction, wash with 100ml deionized water for 3 times, and dry at 70°C for 10 hours to obtain powder C; put powder ...

Embodiment 3

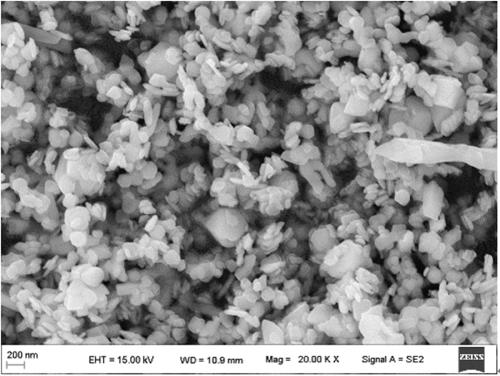

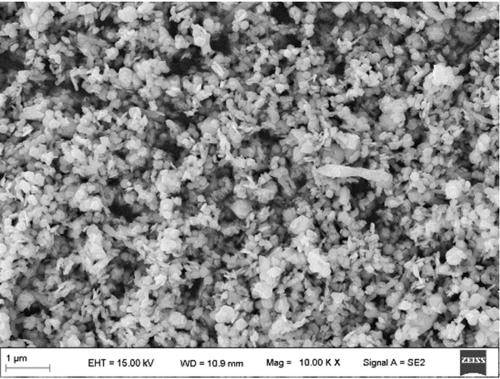

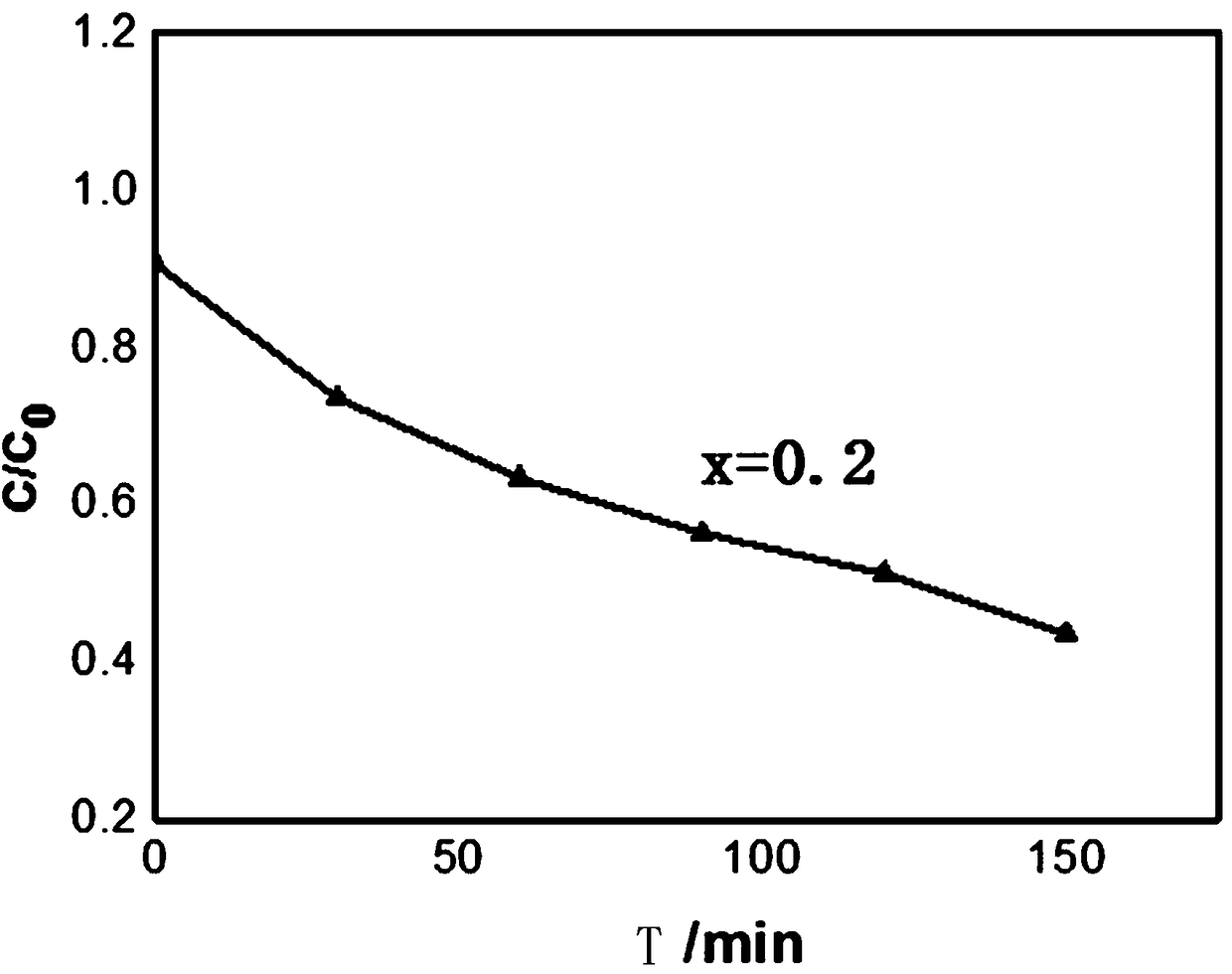

[0051] a kind of Ag 2 MoO 4 The preparation method (x=0.2) of the visible light catalytic composite material comprises the following steps.

[0052] Step 1. Add the mixture of 3mmol ammonium tungstate and 30mmol trimethylammonium bromide (CTAB) into 45ml deionized water, ultrasonically disperse the solution for about 15min, and pour the solution into the flask at the lower end of the Soxhlet extractor. Stir for 50 minutes, and control the temperature of the oil domain at 80°C to obtain solution A.

[0053] Step 2. Weigh a certain amount of nitric acid solution, dissolve it in 50ml of ethanol / water solution, the volume ratio of ethanol to deionized water is 1:10, control the pH of the solution to 5, stir until completely dissolved, and obtain solution B.

[0054] Step 3. Slowly pour solution B into solution A, stir for 15 hours, filter the resulting suspension with suction, wash 3 times with 100ml deionized water, and dry at 80°C for 12 hours to obtain powder C; put powder C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com