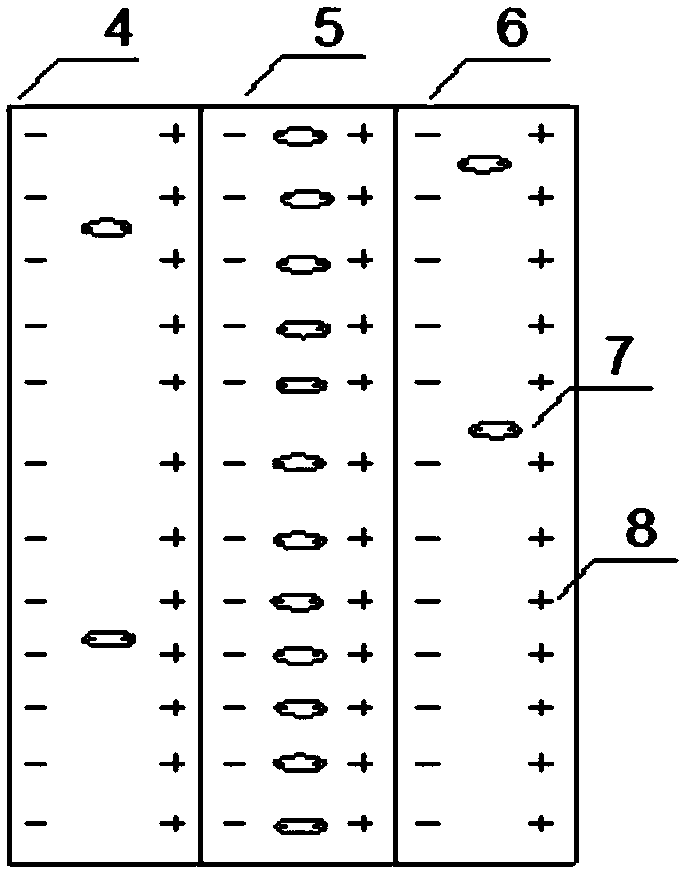

High and low dielectric polymer composite electret filter material and preparation method thereof

A technology of dielectric polymers and filter materials, applied in filtration separation, membrane filters, separation methods, etc., can solve the problems of insufficient mechanical strength of fiber membranes, poor charge storage stability, and high cost of filter materials, and achieve long-term stable filtration efficiency , large insulation resistance, simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A high and low dielectric polymer composite electret filter material and its preparation method in this embodiment, the specific steps are:

[0038] (1) Accurately weigh 13.2g of N-N dimethylformamide and 13.2g of tetrahydrofuran in a 50mL beaker with an electronic balance, then weigh 0.02g of nano-polytetrafluoroethylene (purity 99.5%, average particle size 20nm) and place in the above In the mixed solvent, vibrate with an ultrasonic oscillator for 1.5h, then accurately weigh 3.6g of polystyrene with an electronic balance and place it in the above-mentioned beaker, add a stirring bar, and stir on a magnetic stirrer for 8 hours to form a uniform and stable spinning solution. Silk liquid, number 1. Accurately weigh 13.2g of N-N dimethylformamide and 13.2g of tetrahydrofuran in a 50mL beaker with an electronic balance, then weigh 3.6g of polyvinyl chloride and place it in the above mixed solvent, add a stirring bar, and stir on a magnetic stirrer for 8 Hours, it is confi...

Embodiment 2

[0044] A high and low dielectric polymer composite electret filter material and its preparation method in this embodiment, the specific steps are:

[0045] (1) Accurately weigh 13.2g of N-N dimethylformamide and 13.2g of tetrahydrofuran with an electronic balance and place them in a 50mL beaker, then weigh 0.02g of nano polychlorotrifluoroethylene (purity 99.5%, average particle size 30nm) and place in In the above mixed solvent, vibrate with an ultrasonic oscillator for 1.5h, then accurately weigh 3.6g of polystyrene with an electronic balance and place it in the above beaker, add a stirrer, and stir on a magnetic stirrer for 8 hours to form a uniform and stable solution. Spinning solution, number 1. Accurately weigh 26.4g of N-N dimethylformamide with an electronic balance and place it in a 50mL beaker, then weigh 3.6g of polyacrylonitrile and place it in the above mixed solvent, add a stirring bar, stir on a magnetic stirrer for 6 hours, and configure Become a uniform and ...

Embodiment 3

[0051] The preparation method of a high and low dielectric polymer composite electret filter material in this embodiment, the specific steps are:

[0052] (1) Accurately weigh 12.75g of N-N dimethylformamide and 12.75g of tetrahydrofuran in a 50mL beaker with an electronic balance, then weigh 0.025g of nano-polytetrafluoroethylene (purity 99.5%, average particle size 100nm) and place in the above In the mixed solvent, vibrate with an ultrasonic oscillator for 1.5 hours, then accurately weigh 4.5g of polyamide with an electronic balance and place it in the above mixed solvent, add a stirrer, stir on a magnetic stirrer for 10 hours, and configure it into a uniform and stable Spinning solution, number 1. Accurately weigh 13.2g of N-N dimethylformamide and 13.2g of tetrahydrofuran with an electronic balance and place them in a 50mL beaker. After stirring on a magnetic stirrer for 8 hours, it was configured into a uniform and stable spinning solution, numbered 2.

[0053] (2) use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com