Rectifying and recovering device and method for rectifying and recovering acetone in acetone water solution

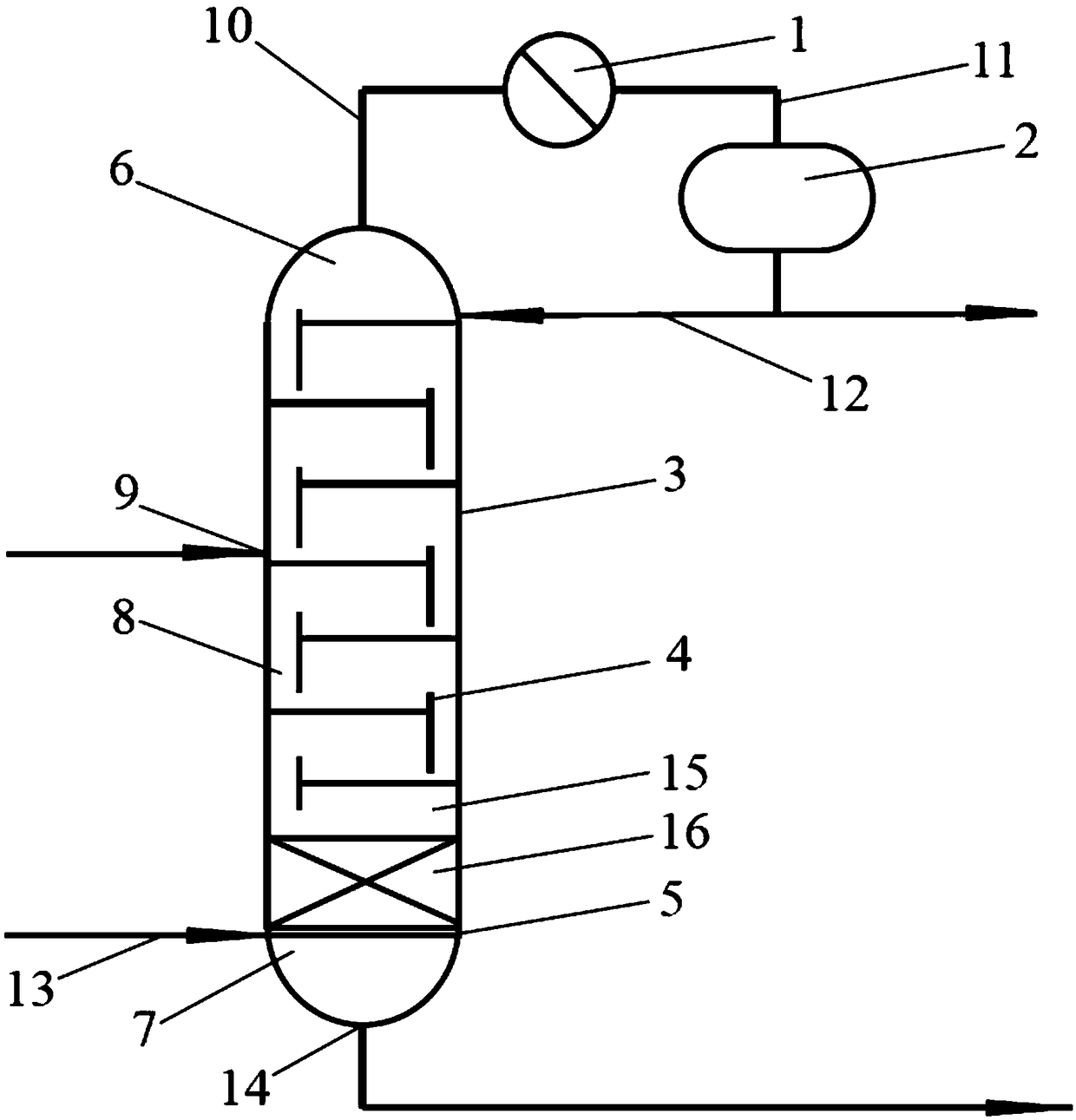

A recovery device and rectification technology are applied in the field of rectification and recovery of acetone in aqueous acetone solution, and the rectification recovery device field can solve the problems of small heat transfer and mass transfer coefficient, poor gas-liquid contact, short gas-liquid contact time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The flow rate is 7200kg / hr and the acetone mass concentration is 60% acetone aqueous solution is that temperature is 60 ℃, under the situation that pressure is 0.12MPa, send in the rectification tower 3 through feed inlet 9, tower still 7 internal gas distributor 5 The top is filled with Sulzer BX wire mesh corrugated structured packing with a height of 0.3m. The overhead steam (98.5%wt of acetone, 1.5%wt of water) is condensed into the liquid storage tank 2 through the condenser 1, and a part in the condensate is collected as the acetone product, and another part is refluxed in the rectifying tower 3 as the reflux liquid , the operating pressure at the top of the tower is 0.1MPa. The rectification tower 3 is heated by stripping direct steam, the flow rate is 3438kg / hr, the temperature is 111.4°C, and the heating steam with a pressure of 0.15MPa is passed into the tower kettle 7 through the inlet pipe 13, and the operating pressure at the bottom of the tower is controll...

Embodiment 2~8

[0030] The processing method of embodiment 2~8 is all identical with embodiment 1, and wherein embodiment 2 and 3 adopt the Sulzer BX500 type wire mesh corrugated packing identical with embodiment 1, and packing height is respectively 0.5m and 0.8m; Embodiment 4 to 6 all use Sulzer Mellapak 250Y orifice corrugated packing, and the packing heights are 0.3m, 0.5mm and 0.8m respectively; Example 7 uses Sulzer Mellapak 250X orifice corrugated packing, and the packing height is 0.5m; In addition, an embodiment 8 without filler is introduced as a comparison of embodiments 1-7, and the process parameters of embodiments 1-8 are shown in Table 1.

[0031] Table 1: The technological parameter of embodiment 1~8

[0032]

[0033] It can be seen from Table 1 that the equal plate height of the Sulzer BX500 wire mesh corrugated packing used in Examples 1 to 3 is 0.23m, and the volume heat transfer coefficient of the tower kettle increases with the increase of the packing height. The equi...

Embodiment 9~14

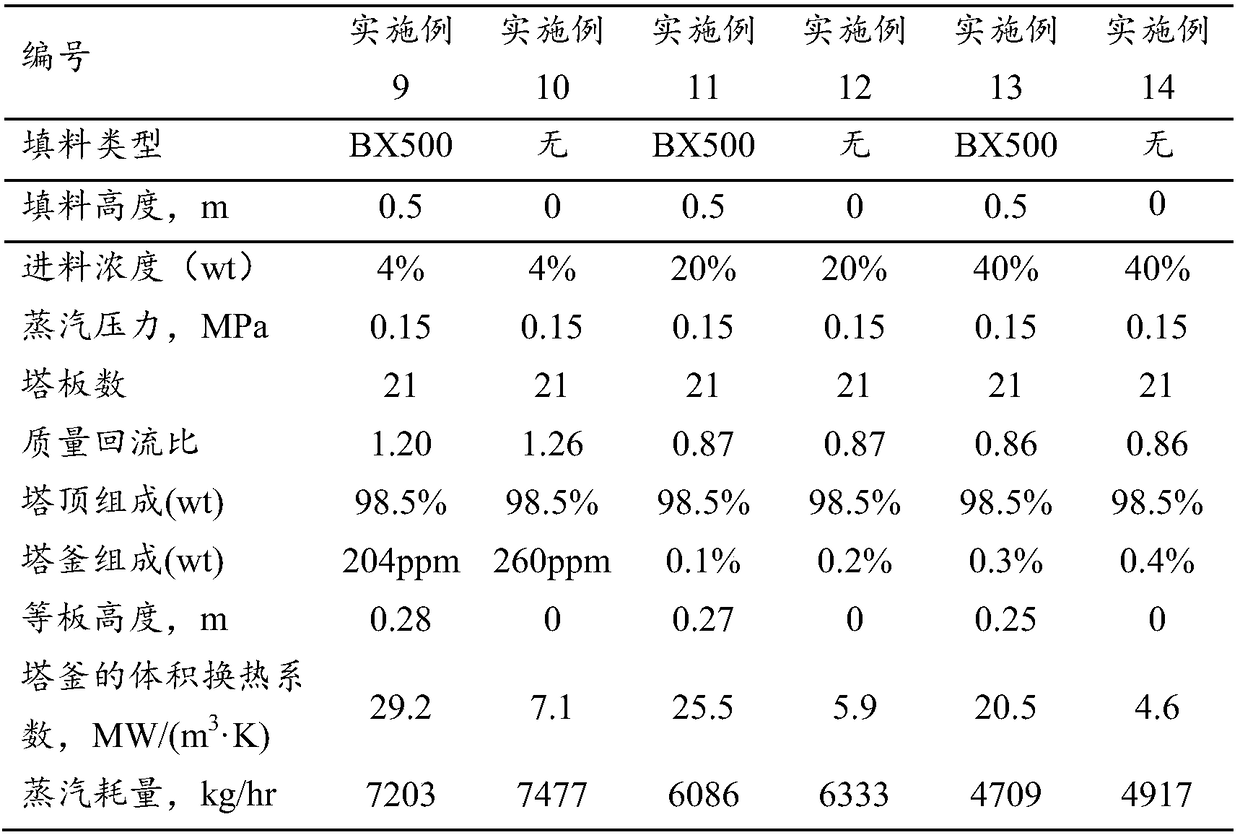

[0037] The processing method of embodiment 9~14 is the same as embodiment 1, and embodiment 9,11,13 select the better BX500 type filler of mass transfer performance, and the height of filler is all set to 0.5m, after changing feed concentration, still stipulate the quality of acetone at the top of the tower The concentration is 98.5%, the mass recovery rate is 99%, and the operating conditions such as the reflux ratio and recovery of the rectification tower are optimized to obtain a volumetric heat transfer coefficient and steam consumption different from that of Example 2. Examples 10, 12, and 14 do not have fillers, and are respectively used as comparisons of Examples 9, 11, and 13 at the same feed concentration. The process parameters of Examples 9-14 are shown in Table 2.

[0038] Table 2: the technological parameter of embodiment 9~14

[0039]

[0040] Comparing Examples 9, 11, 13 and Example 2, along with the increase of acetone concentration in the feed, equal plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com