Production technology of sugared green plums

A production process, green plum technology, applied in the confectionary industry, confectionary, food science, etc., can solve the problems of inability to guarantee nutritional content and loss, shorten the time of salting, avoid the loss of nutrient content, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

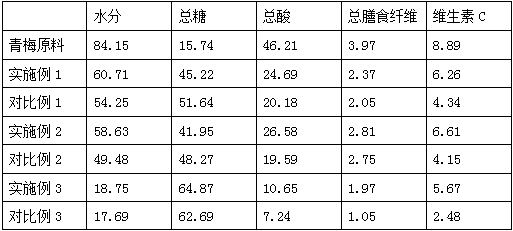

Embodiment 1

[0038] The candied greengage is processed according to the following steps: (a) select 6 mature greengages, remove the stems, wash with 0.2% salt water, and dry; (b) prepare a solution of 9% salt and 0.15% food-grade mannitol in mass concentration. Put the cleaned and dried green plum into the solution to pickle for 7 days. (c) Put greengage into a container and pour plenty of water. Soak for 4 hours, drain the water in the container after stirring, and inject a large amount of clean water again; after repeating 2 times, dry the greengage. (d) Weigh 30kg of sucrose, 0.2kg of mannitol, dissolve in 70kg of water, 5g of tartrazine and indigo, put in greengage, whichever is just submerged, and seal it for 20 days; remove and drain. (e) Drying: Put the mixed ingredients into the drying and cooling integrated equipment, turn on the drying function, set the heating rate to 5°C / min, heat it to 40°C and keep it warm for 120 minutes.

Embodiment 2

[0042] The candied greengage is processed according to the following steps: (a) select 7 mature greengages, remove the stems, wash with 0.5% salt water, and dry; (b) prepare a solution with a mass concentration of 8% salt and 0.1% food-grade sorbitol. Put the cleaned and dried green plum into the solution to pickle for 7 days. (c) Put greengage into a container and pour plenty of water. Soak for 5 hours, drain the water in the container after stirring, and inject a large amount of water again; after repeating 3 times, dry the greengage. (d) Weigh 20kg of sucrose, 0.1kg of mannitol, dissolve in 80kg of water, 3g of tartrazine and indigo, put in greengage, whichever is just submerged, seal it for 30 days; remove and drain. (e) Drying: Put the mixed ingredients into the integrated drying and cooling equipment, turn on the drying function, set the heating rate at 5°C / min, heat it up to 50°C and keep it warm for 80 minutes.

Embodiment 3

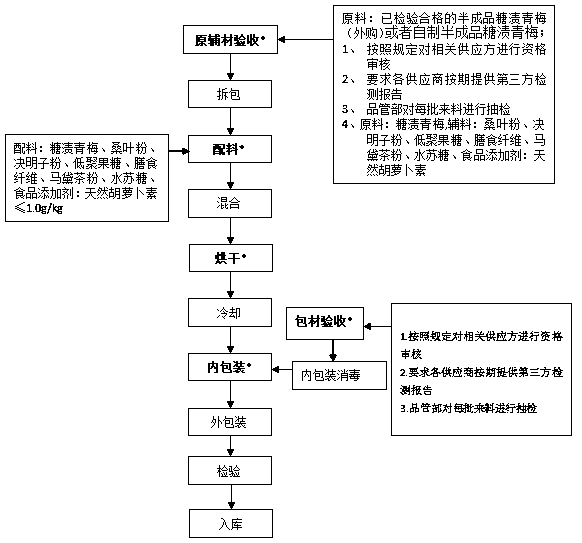

[0046] A kind of candied green plum production technology, concrete processing comprises the following steps:

[0047] (1) Acceptance of raw and auxiliary materials, which include raw materials and auxiliary materials. The raw material is the candied green plum prepared in Example 1. The auxiliary materials are mulberry leaf powder, cassia seed powder, fructooligosaccharide, dietary fiber, yerba mate tea powder, stachyose, food additive: natural carotene.

[0048] (2) Unpacking.

[0049] (3) Ingredients, the ingredients are 20Kg candied green plum, 0.1Kg mulberry leaf powder, 0.15Kg cassia seed powder, 0.10Kg fructooligosaccharide, 0.01Kg dietary fiber, 0.25Kg yerba mate tea powder, 0.1Kg stachyose, 10g The proportion of natural carotene is obtained by weighing raw and auxiliary materials.

[0050] (4) Mixing: Pour the ingredients into a stainless steel stirrer equipped with a heater and stir evenly. During the stirring process, the temperature is controlled at 30°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com