High-strength and high-toughness bridge cable zinc-coated steel wire and preparation method thereof

A galvanized steel wire and cable technology, applied in the field of bridge cable steel wire, can solve the problems of energy-consuming process, poor torsional performance, low strength, etc., and achieve the effects of improving working conditions, reducing production costs, and avoiding damage to plasticity and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

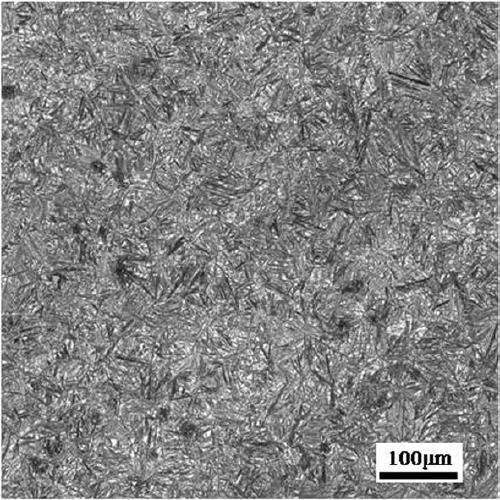

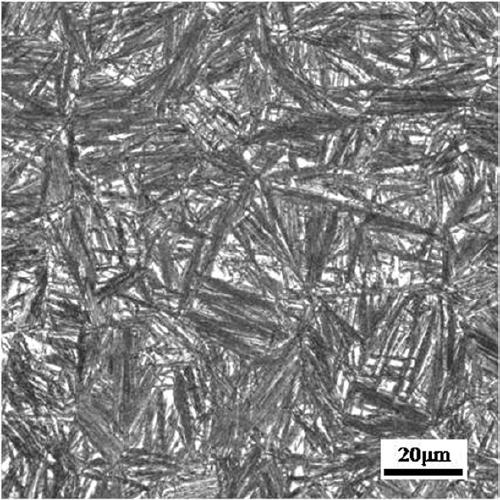

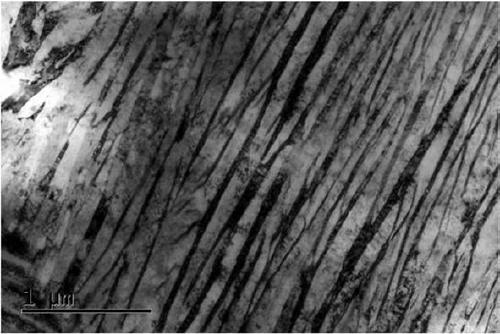

Image

Examples

preparation example Construction

[0043] A method for preparing galvanized steel wire for high-strength bridge cables, the specific steps of the method are as follows:

[0044] Step 1: Hot rolling: heat the continuous casting slab to a certain temperature and then anneal and heat-preserve it to ensure that the composition of the slab is completely uniform, and then roll it through multiple passes. hot-rolled bars;

[0045] Step 2: hot drawing: the hot-rolled bar is hot-drawn at high temperature to obtain bridge cable steel wires with different size requirements;

[0046] Step 3: Austempering: Austempering the hot-rolled steel wire in Step 2, keeping it warm for several hours, and then taking it out and air cooling to room temperature;

[0047] Step 4: Surface treatment: pickling, washing and spraying the hot-rolled steel wire to remove the industrial salt attached to the surface and the scale produced by decarburization;

[0048] Step 5: Hot-dip galvanizing: Send the surface-treated steel wire into the galv...

Embodiment 1

[0056] A high-strength and toughness bridge cable galvanized steel wire, the chemical composition of the steel wire is: C 0.75%, Si 1.40%, Mn 1.55%, Cr 0.90%, Al 1.10%, Mo 0.10%, Co 0.90%, Nb 0.02%, the balance is Fe and impurity elements.

[0057] A method for preparing galvanized steel wire for high-strength bridge cables, the specific steps of the method are as follows:

[0058] Step 1: Hot rolling: heat the continuous casting slab to 1200°C and keep it warm for 6 hours to ensure that the composition of the slab is completely homogenized, and then hot rolling at 1050°C for 5 to 8 times. hot-rolled bars;

[0059] Step 2: Hot drawing: the hot-rolled bar is hot-drawn at a high temperature of 800°C to obtain bridge cable steel wires with different size requirements; the drawing speed is controlled at 100mm / s

[0060] Step 3: Austempering: the hot-rolled steel wire in step 2 is subjected to austempering, kept at 200°C for 10 hours, and then taken out and air-cooled to room te...

Embodiment 2

[0064] A galvanized steel wire for high-strength bridge cables, the chemical composition of the steel wire is: C 0.80%, Si 1.55%, Mn 1.8%, Cr 1.20%, Al 1.45%, Mo 0.21%, Co 1.10%, Nb 0.04%, the balance is Fe and impurity elements.

[0065] A method for preparing galvanized steel wire for high-strength bridge cables, the specific steps of the method are as follows:

[0066] Step 1: Hot rolling: heat the continuous casting slab to 1250°C and keep it warm for 4 hours to ensure that the composition of the slab is completely homogenized, and then hot rolling at 1100°C for 5 to 8 times. hot-rolled bars;

[0067] Step 2: Hot drawing: the hot-rolled bar is hot-drawn at a high temperature of 900°C to obtain bridge cable wires of different sizes; the drawing speed is controlled at 105mm / s

[0068] Step 3: Austempering: Austempering the hot-rolled steel wire in Step 2, keeping it at 300°C for 3 hours, then taking it out and air cooling to room temperature;

[0069] Step 4: Surface tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com