Production and application method of porous carbon material with high specific surface area

A porous carbon material and high specific surface area technology, applied in the preparation/purification of carbon, electrical components, battery electrodes, etc., can solve the problems that are not suitable for large-scale production, the process of porous materials is complicated, and the yield is low, and achieve high resistance efficiency, high pore volume, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

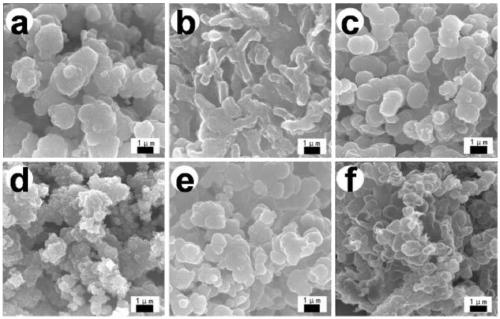

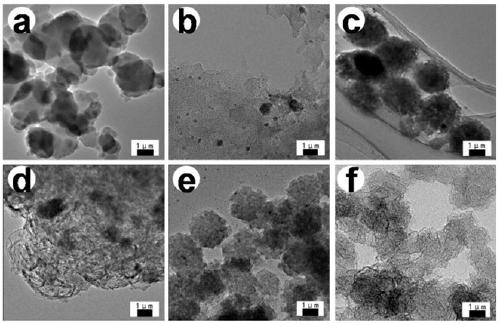

[0037] S1: the simple substance Co of hexachlorobutadiene and transition metal is added in the autoclave with polytetrafluoroethylene liner, reacted 40 hours at 220 ℃, wherein the mol ratio of metal simple substance and hexachlorobutadiene is 1:30;

[0038] S2: After the reaction is finished, cool to room temperature naturally, and dry the obtained solid at 220° C. for 6 hours to obtain a dry sample;

[0039] S3: The dry sample was heated to 1000° C. at a heating rate of 10° C. / min under nitrogen protection, and calcined for 2 hours to obtain porous carbon materials, which were respectively named M-1000.

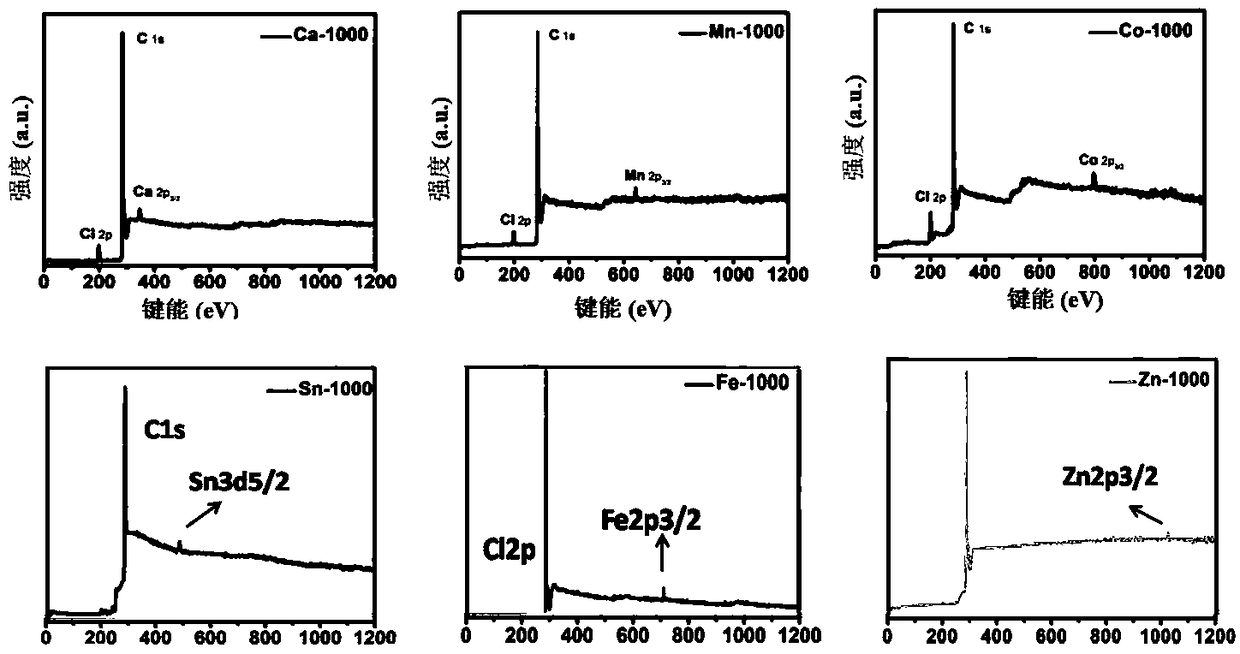

Embodiment 2-6

[0040] Embodiment 2-6, the investigation of metal simple substance in the step S1

[0041] Except that the simple metal substance in step S1 is replaced by Fe, Zn, Ca, Sn and Mn, etc., other operations are all the same, so that the operation of Example 1 is repeated, so that the examples 2-6 are carried out in sequence, and the resulting composite materials are named sequentially. For Fe-1000, Zn-1000, Ca-1000, Sn-1000 and Mn-1000 etc.

Embodiment 7-9

[0042] Embodiment 7-9, the investigation of roasting temperature in the step S3

[0043] Except that the high-temperature calcination temperature in step S3 was replaced from 1000°C to 800°C, 900°C and 1100°C respectively, other operations remained unchanged, so that Example 1 was repeated, and the materials of Examples 7-9 were obtained in sequence. The resulting composites were therefore named M-800, M-900 and M-1100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com