Device and method for extracting carbon source of sewage treatment plant from kitchen waste

A technology for sewage treatment plants and kitchen waste, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., to achieve easy operation, reduce odor, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Soak kitchen waste and 55°C hot water for 1 hour at a ratio of 1 kg: 2 L, and filter to obtain the kitchen waste filtrate. Heavy metal indicators of kitchen waste filtrate: Cu 0.09mg / L, Pb 0.28mg / L, Zn 0.54mg / L, Cr<0.03mg / L, Cd 0.02mg / L, Ni0.20mg / L, As 0.0047mg / L, Hg 0.0005mg / L.

[0057] "Water Quality Standards for Discharge of Sewage into Urban Sewers" (GB 31962-2015) control item limits (A level) are: Cu2mg / L, Pb 0.5mg / L, Zn 5mg / L, Cr 1.5mg / L, Cd 0.05mg / L L, Ni 1mg / L, As 0.3mg / L, Hg0.005mg / L.

[0058] "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB 18918-2002) the maximum allowable discharge concentration is: Cu0.5mg / L, Pb 0.1mg / L, Zn 1.0mg / L, Cr 0.1mg / L, Cd 0.01mg / L L, Ni 0.05mg / L, As 0.1mg / L, Hg 0.001mg / L.

[0059] The heavy metal indicators of the kitchen waste filtrate are far lower than the control item limits of the "Water Quality Standards for Sewage Discharge into Urban Sewers" (GB31962-2015); the indicators except for Pb, Cd and Ni a...

Embodiment 2

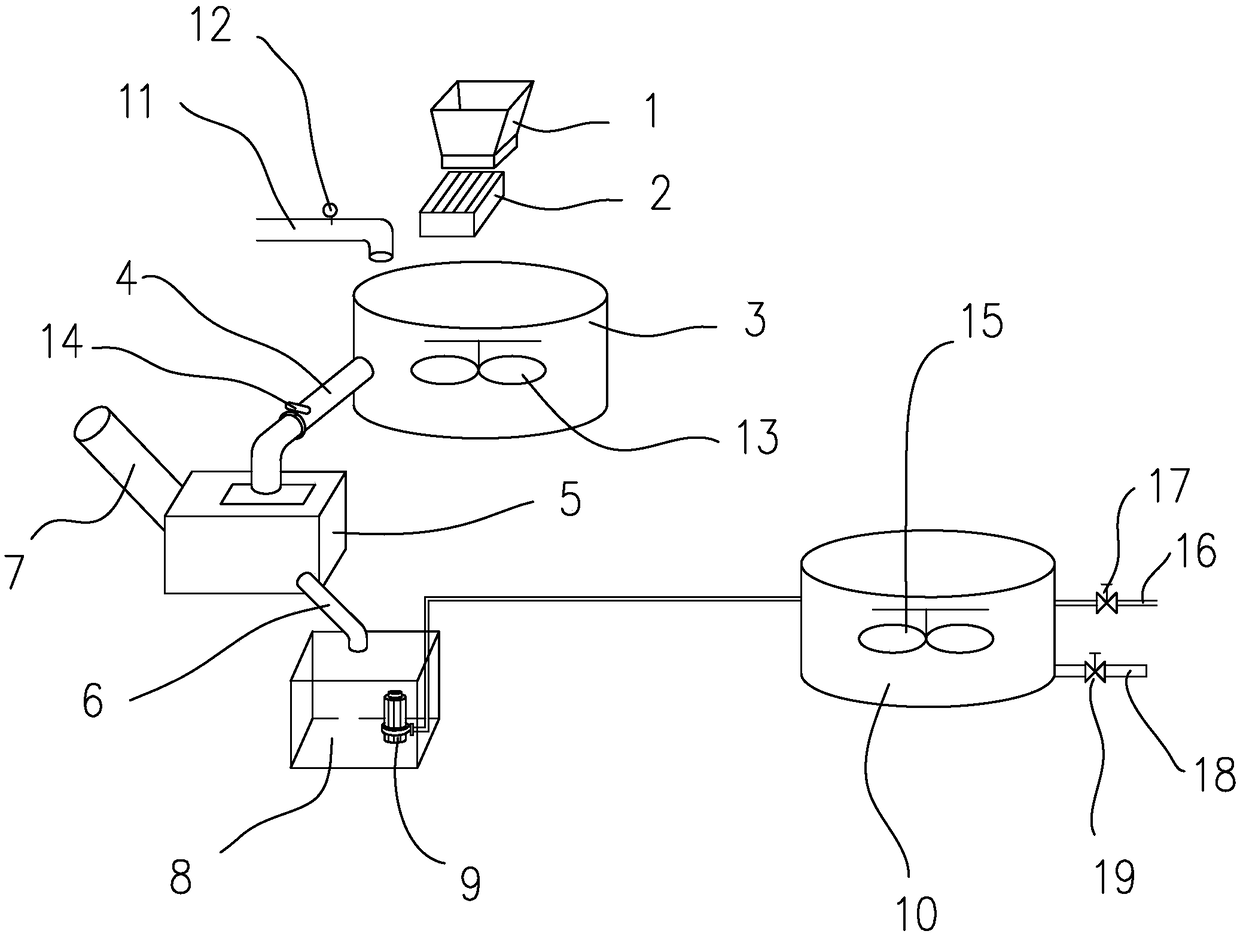

[0062] The kitchen waste is transported to the crusher and the crushing grid by gravity conveying or manual shovel, so that the diameter is less than 20mm. The kitchen waste is fresh kitchen waste produced within 3 days, with a moisture content of about 80%. Then it is transported by gravity into the soaking pool, where 55°C hot water is added (the mass ratio of kitchen waste to hot water for soaking is 1:1.5), and soaked for 30 minutes. The solid-liquid mixture in the soaking tank is sent to the squeezer for squeezing, and separated into kitchen waste residue and kitchen waste filtrate. Take 3L filtrate in a beaker, first add 5.22g FeCl 3 (mass fraction 38%), then add 32.2g CaO (mass fraction 65%, 180 mesh), after stirring at 200r / min for 1min, then 100r / min for 5min. After coagulation, the kitchen waste filtrate was left to stand for 30 minutes, and the supernatant was taken for testing. The removal rate of TN can reach more than 41%, the removal rate of TP can reach more...

Embodiment 3

[0064] The kitchen waste is transported to the crusher and the crushing grid by gravity conveying or manual shovel, so that the diameter is less than 20mm. The kitchen waste is fresh kitchen waste produced within 3 days, with a moisture content of about 80%. Then it is transported by gravity into the soaking pool, where 55°C hot water is added (the mass ratio of kitchen waste to hot water for soaking is 1:1.5), and soaked for 30 minutes. The solid-liquid mixture in the immersion tank is sent to the squeezer for squeezing, separated into kitchen waste residue and kitchen waste filtrate, and the kitchen waste filtrate is transported to the coagulation reaction device. equipped with 3m 3 In the coagulation reaction device of kitchen waste filtrate, add 0.33‰FeCl successively 3 Solution (mass fraction 38%) and 0.7% lime powder were stirred at a speed of 200r / min for 1min, and then stirred at a speed of 100r / min for 5min. After coagulation, the kitchen waste filtrate was allowed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com