Modified starch and its preparation method and application

A starch and modification technology, applied in the field of modified starch and its preparation, can solve problems such as difficult control of production conditions, heavy pollution, and impact on product quality, achieve good water and moisture resistance, reduce COD concentration, and reduce starch The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

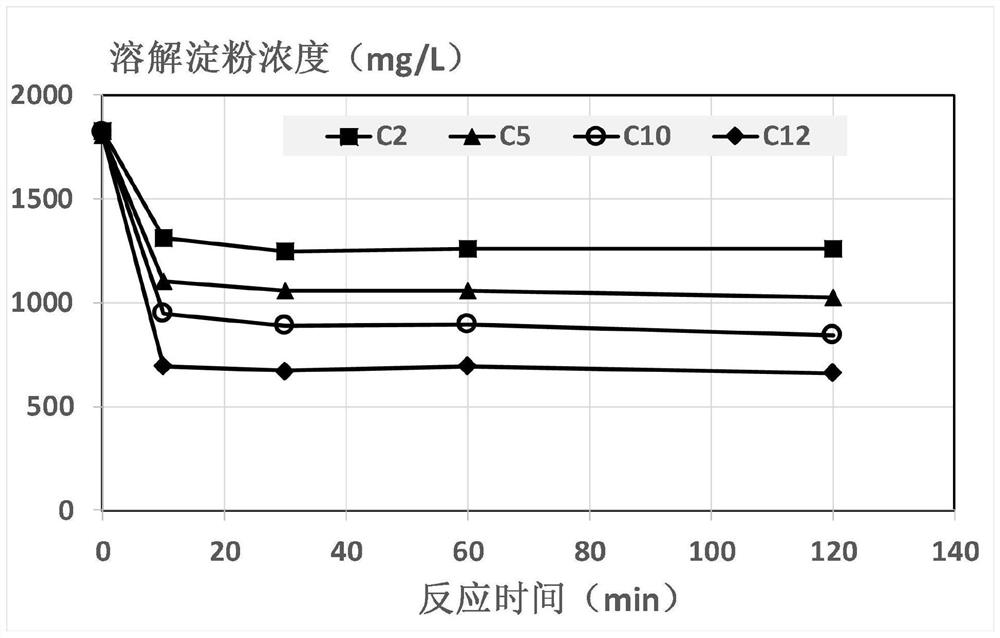

[0351] Example 1 Effect of cationic starch binding agent hexadalkylpyridine hydrochloric acid (number C7) to starch dissolution and fiber surface adsorption after binding reaction

[0352] Experimental step: (1) Take corn amyloid first to prepare 7% "standard starch solution"; (2) take a proper amount of standard starch solution to dilute the concentration of the desired starch solution; (3) take the preformed concentration The starch solution was 500 ml, placed in a beaker, and was placed in a constant temperature water bath 45 ° C, equilibrated to the specified temperature; (4) adding C7 in accordance with the desired concentration, reacting 60 minutes, modified starch solution; (5) Sampling centrifugation 4000X g) 5 minutes, take the supernatant test starch concentration; (6) Add bleaching chemical seizing (BKP) in the residual modified starch solution, maintaining the stirring time 10 minutes; (7) After the reaction, take The slurry was centrifuged (4000 x g) for 5 minutes, an...

Embodiment 2

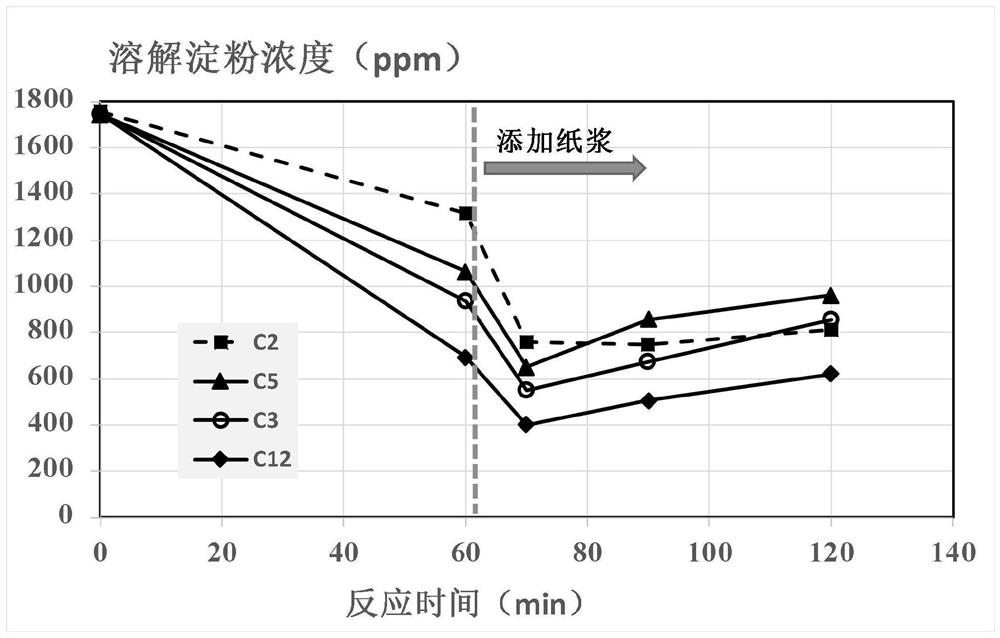

[0358] Effect of Example 2 Reaction Time on Starch Binding Reaction

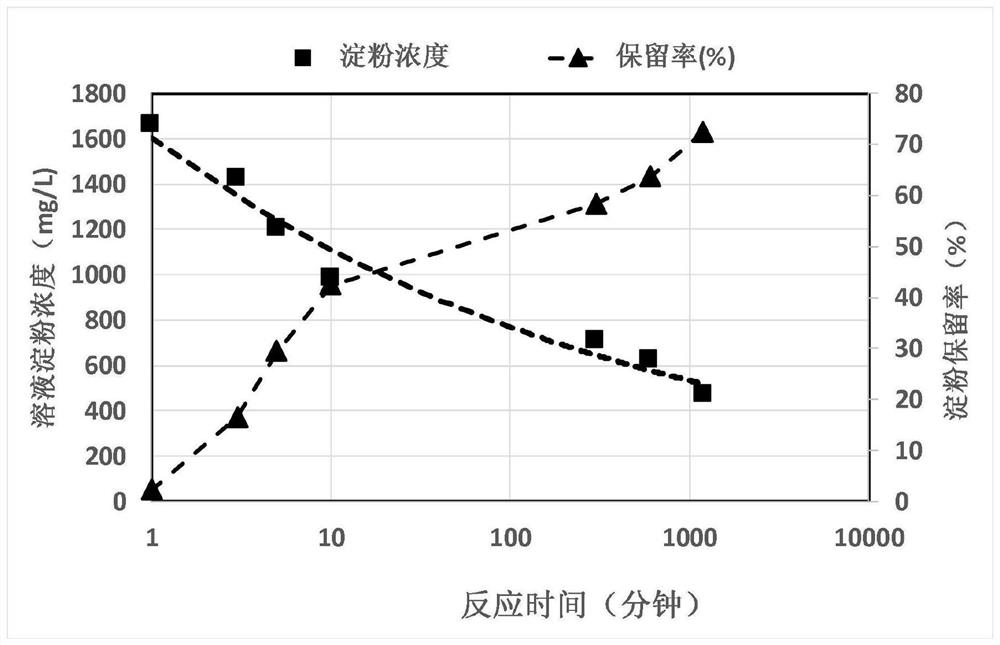

[0359]Experimental step of starch reaction: (1) Take corn amyloid first to prepare 7% "standard starch solution"; (2) Take a proper amount of standard starch solution to add ion water to the starch concentration of about 1800 mg / L (or other desired concentration) (3) Take the preformed concentration of starch solution 500ml or OCC white water, place the beaker, and put it into a 40 mg / L starch binding agent to the specified temperature; (4) to the designated temperature; (4) When the reaction reaches 1, 3, 5, 10, 30, 60, 90, 120, 300, 600 and 1200 minutes, sample centrifugation (4000 x g) for 5 minutes, take the supernatant test starch content and COD concentration;

[0360] Test step of the starch adsorption reaction time: Step (1) - (4) Suitress, (5) When the starch reaction reacted for 60 minutes, 3% chemical seizing (BKP) was added according to the required pulp concentration, stirred and started to adso...

Embodiment 3

[0365] Example 3 The reaction temperature on starch binding reaction and the effect of adsorption of modified starch

[0366] Experimental step: (1) Take a corn starch sample to prepare 7% "standard starch solution"; (2) Take a proper amount of standard starch solution to add ion water to the starch concentration of about 600 mg / L; (3) take the preformed concentration of starch solution 500ml, placed in a beaker, and put into a constant temperature water bath in advance to test the test temperature, equilibrate to the designated temperature; (4) Add 30 mg / L cation starch binding agent C7, react 60 minutes, Modified starch solution; (5) Sampling centrifugation (4000 x g) 5 minutes, take the supernatant test starch content and COD concentration; (6) Add chemical secting in the remaining modified starch solution (BKP) (Note: The amount of starch binding agent is equivalent to 1000 g / t sterilizing pulp), retains stir; (7) reaction for 10 minutes, penetrating centrifugation (4000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com