A method for determining the segregation state of an alloy surface and a method for manufacturing the alloy

A technology of alloy and state, applied in computer combinatorial chemistry, chemical process analysis/design, etc., can solve problems such as large differences, ensuring whether segregation occurs on the surface of materials, and inability to calculate accurately, to achieve high precision, fast and accurate judgment, The effect of quick judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

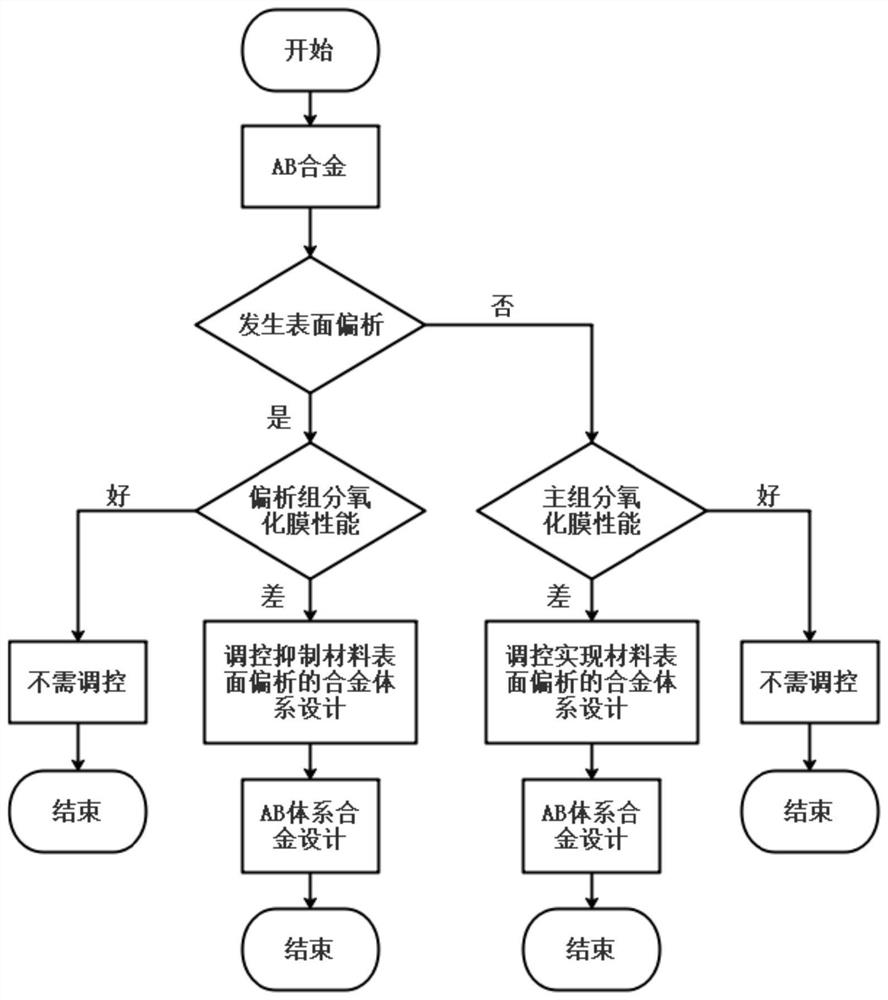

[0033] A method for judging the surface segregation state of stainless steel Fe-Cr alloy and manufacturing stainless steel Fe-Cr alloy material. First, if figure 1 As shown, it is determined whether the surface segregation of the Fe-Cr alloy occurs and the elemental composition of the alloy is selected.

[0034] The design calculation method for determining whether surface segregation occurs in Fe-Cr alloy is:

[0035] W=E(Fe-Cr)-1 / 2[E(Fe-Fe)+E(Cr-Cr)], wherein, E(Fe-Cr)=75kJ / mol, E(Fe-Fe)=118kJ / mol mol, E(Cr-Cr)=152kJ / mol, calculated according to the formula: W=-60kJ / mol, that is, W<0, so it can be determined that element surface segregation will occur in Fe-Cr alloy. According to the comparison of the surface tension values of the two elements, it can be seen that the surface tension of the Fe element is greater than that of the Cr element, so it can be determined that the surface segregation of the Fe element will occur in the Fe-Cr alloy.

[0036] In order to suppress...

Embodiment 2

[0040] A method for judging the surface segregation state of a silicon steel Fe-Si alloy and manufacturing a silicon steel Fe-Si alloy material. First, if figure 1 As shown, determine whether the surface segregation of Fe-Si alloy occurs and select the elemental composition of the alloy.

[0041] The design calculation method for determining whether surface segregation occurs in Fe-Si alloy is:

[0042] W=E(Fe-Si)-1 / 2[E(Fe-Fe)+E(Si-Si)], wherein, E(Fe-Si)=297kJ / mol, E(Fe-Fe)=118kJ / mol mol, E(Si-Si)=310kJ / mol, calculated according to the formula: W=83kJ / mol, that is, W>0, so it can be judged that the Fe-Si alloy will not segregate on the surface of elements.

[0043] Considering that in the Fe-Si silicon steel alloy, the surface tension of Fe is much greater than that of Si, and the iron oxide film formed at high temperature is poor in compactness, which easily leads to the problem of oxide film peeling off, it is necessary to add a third component to realize that this compon...

Embodiment 3

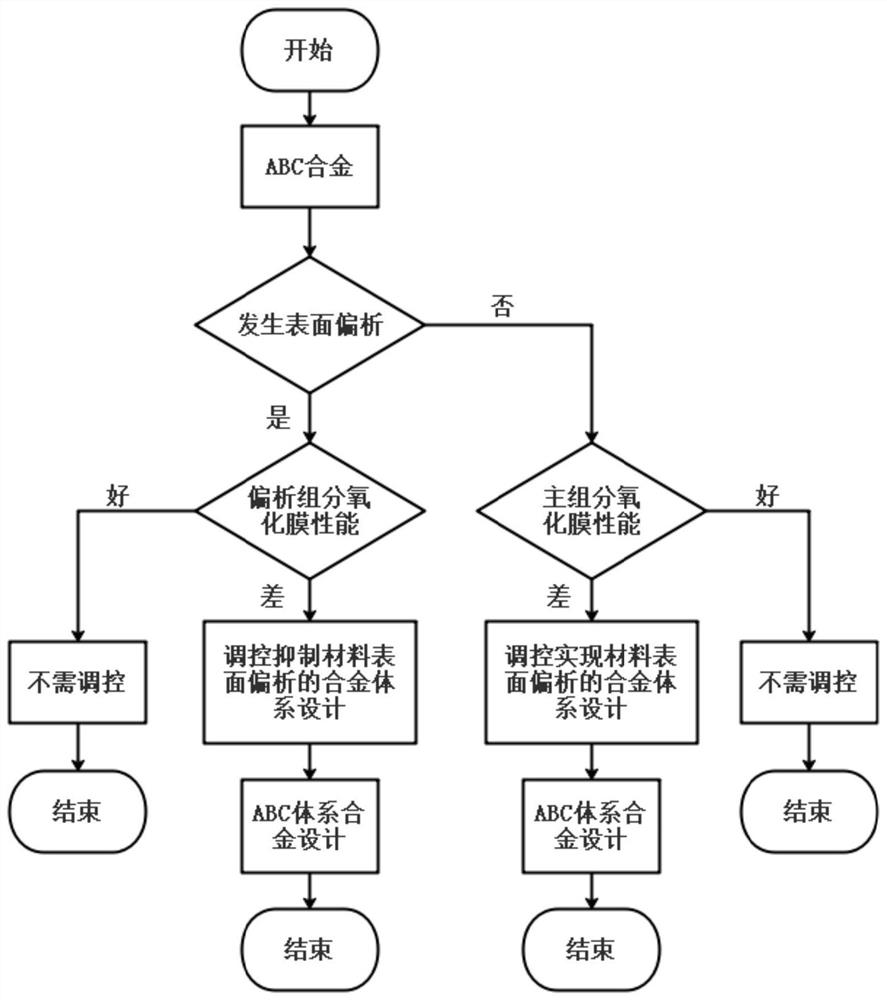

[0047] A method for judging the surface segregation state of Sn-Bi-Ag lead-free solder alloy used in the field of low-temperature soldering and manufacturing Sn-Bi-Ag lead-free solder alloy material. First, if figure 2 As shown, it is determined whether the surface segregation of the Sn-Bi-Ag alloy occurs and the elemental composition of the alloy is selected.

[0048] The design calculation method to determine whether the alloy has surface segregation is to calculate the following parameter values respectively:

[0049] W1=E(Sn-Bi)-1 / 2[E(Sn-Sn)+E(Bi-Bi)],

[0050] W2=E(Sn-Ag)-1 / 2[E(Sn-Sn)+E(Ag-Ag)],

[0051] W3=E(Bi-Ag)-1 / 2[E(Bi-Bi)+E(Ag-Ag)], wherein, E(Sn-Bi)=180kJ / mol, E(Sn-Sn)=187kJ / mol, E(Bi-Bi)=196.6kJ / mol, E(Sn-Ag)=157kJ / mol, E(Ag-Ag)=162.9kJ / mol, E(Bi-Ag)=192kJ / mol, according to the formula Calculations can be obtained: W1=-11.8, W2=-17.95, W3=12.25. At this time, W3>0, W2<W1<0, so it can be judged that the surface segregation of Ag element in this alloy will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com