Door sealing structure used in shield starting and receiving construction and construction method of structure

A technology of shield tunneling during construction, which is applied in the direction of foundation structure engineering, earthwork drilling, and sheet pile walls, etc. The effect of small wear of the cutter head and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

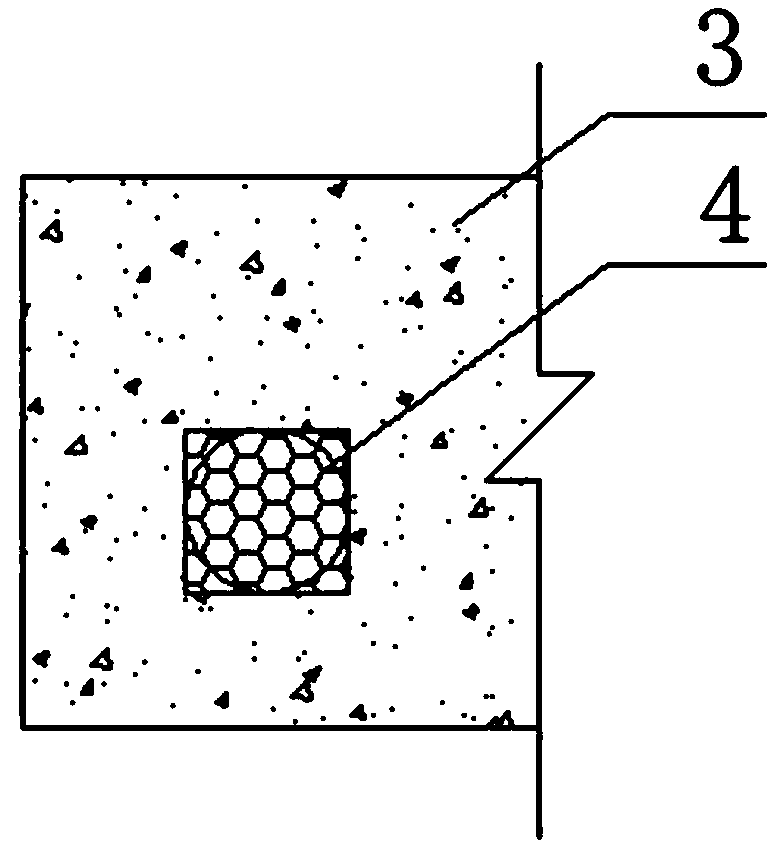

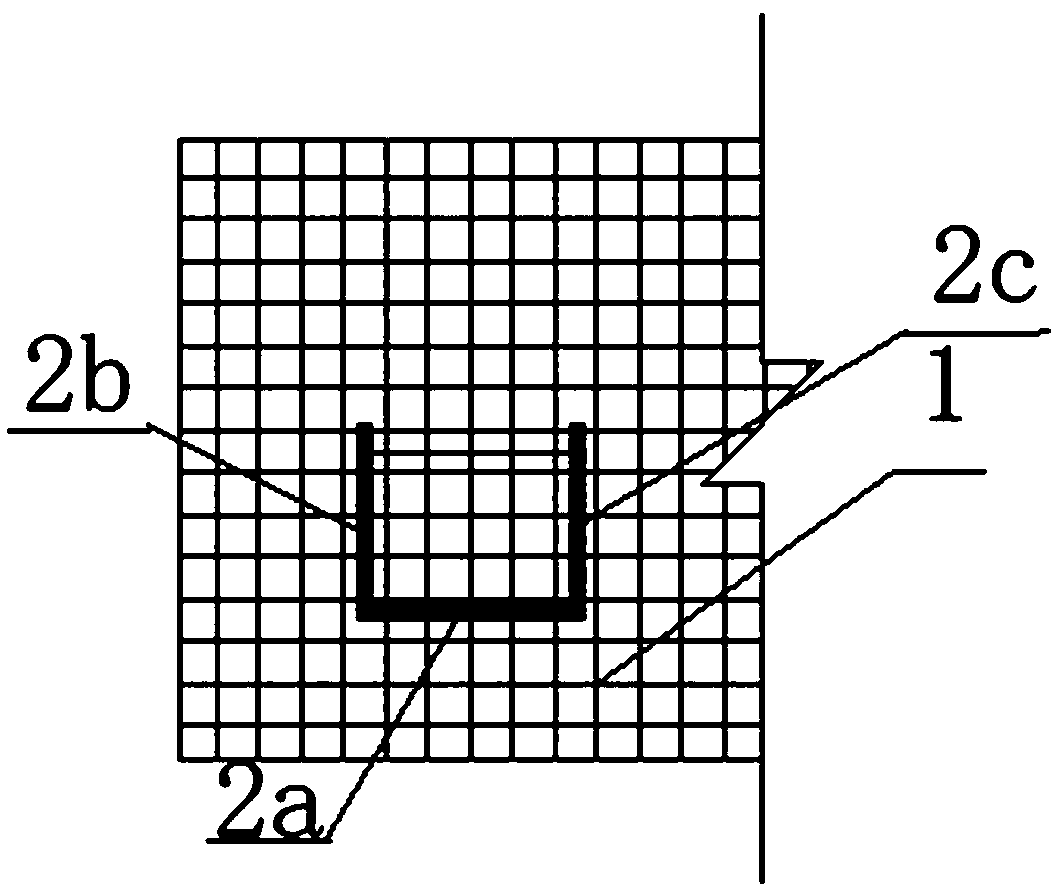

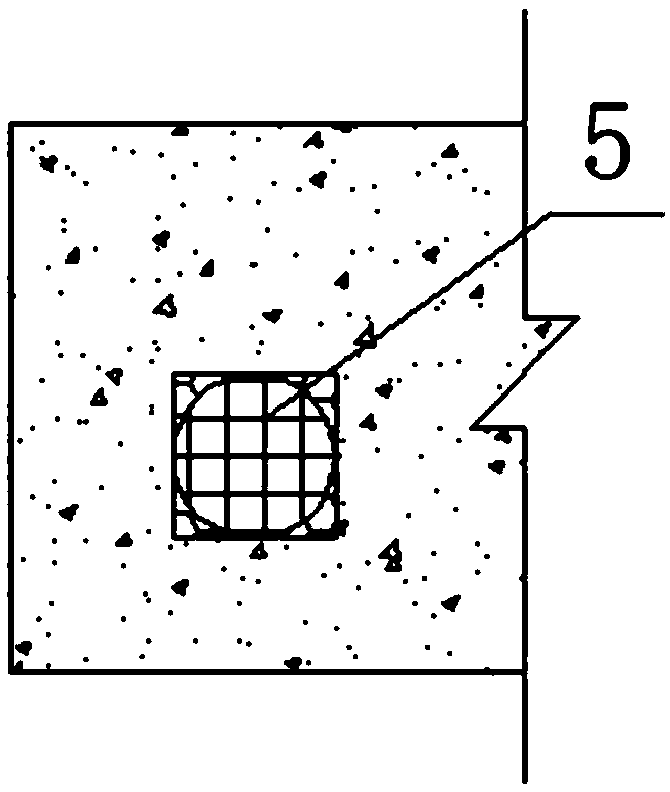

[0027] figure 2 It shows a door-sealing structure used in shield launching and receiving construction, which includes an underground continuous wall: a steel cage embedded in concrete as a skeleton, and the bottom of the shield circular penetration area corresponding to the steel cage 1 is transversely A bottom steel plate 2a is welded, and two side steel plates 2b and 2c of the same size as the bottom steel plate are respectively vertically welded on the left and right sides of the bottom steel plate to form a square upper opening steel formwork, and the corresponding vertical steel bars on the reinforcement cage 1 and The upper and lower surfaces of the bottom steel plate are welded together, and multiple steel bars are welded horizontally between the two side steel plates 2b and 2c; the length of the above bottom steel plate 2a is the diameter of the tunnel plus 1m, the thickness is 2cm to 5cm, and the width is equal to the thickness of the underground diaphragm wall ; Sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com