High-temperature-resistence viscosity-reducing adhesive tape and preparation method thereof

A kind of adhesive tape and high temperature technology, which is applied in the field of high temperature adhesive tape and its preparation, can solve the problems of residual adhesive risk and other problems, and achieve the effects of reducing the risk of residual adhesive, cost advantages, and reduced peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

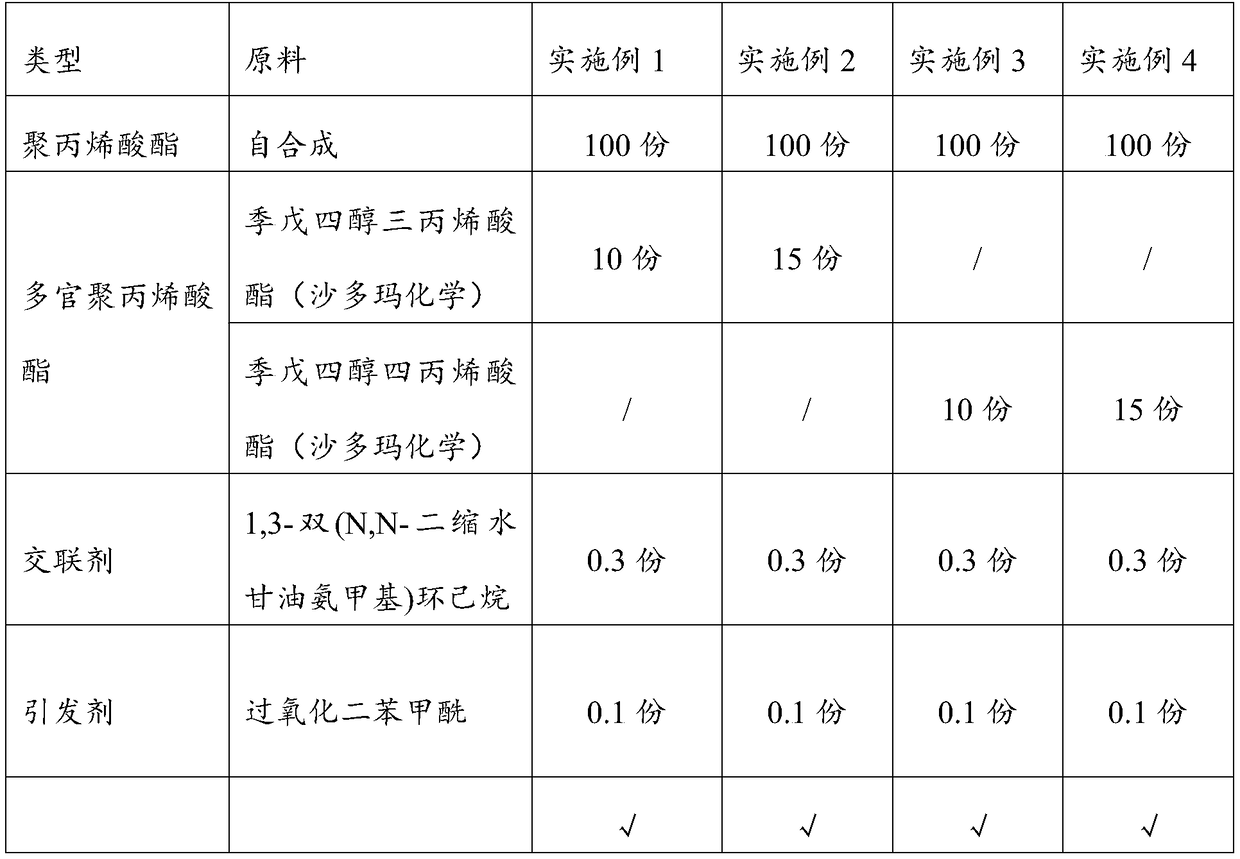

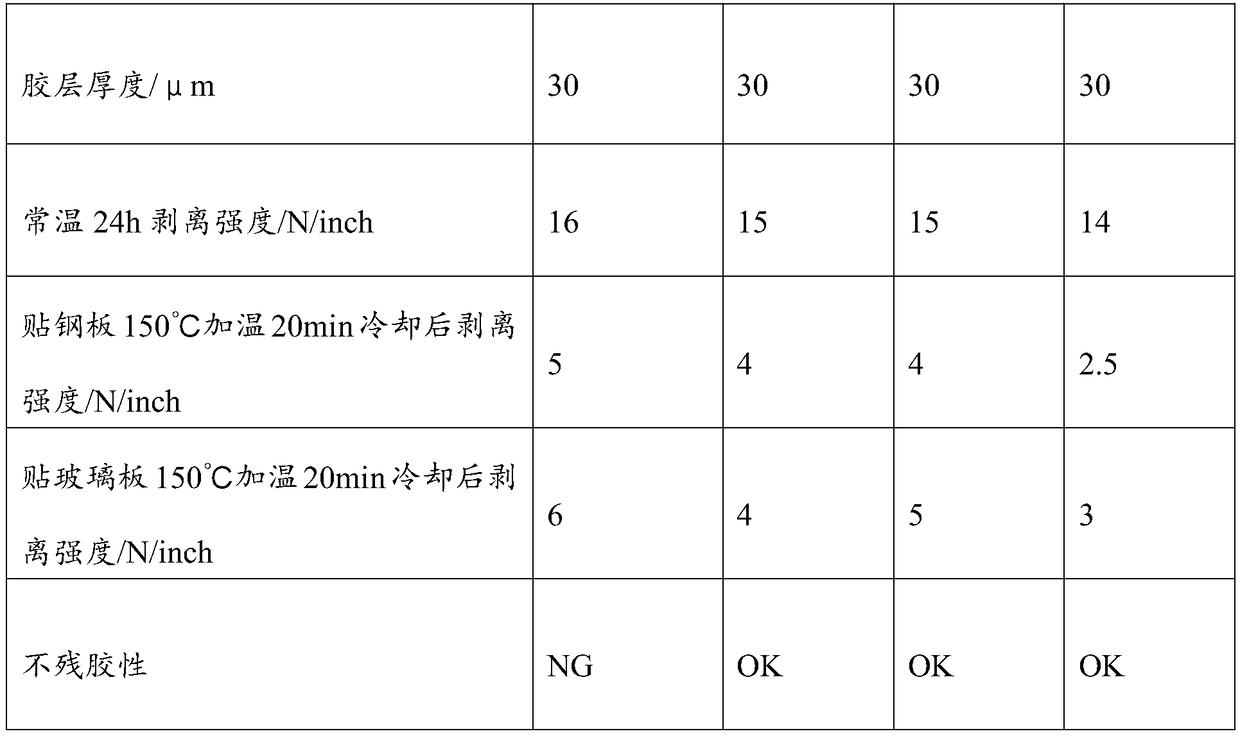

[0031] The raw materials used in the high-temperature viscosity-reducing polyacrylate pressure-sensitive adhesives of Examples 1 to 4 are shown in Table 1:

[0032] Table 1: Types of raw materials used in the high-temperature tack-reducing polyacrylate pressure-sensitive adhesives of Examples 1-4

[0033]

[0034] The preparation method of the high temperature adhesive tape of embodiment 1~4 is as follows:

[0035] 1) Put 40 parts of isooctyl acrylate, 5 parts of acrylic acid, 1 part of hydroxyethyl methacrylate, 0.2 parts of azobisisobutyronitrile and 60 parts of ethyl acetate into the reaction kettle, under the condition of nitrogen gas, 65-68 ℃ for 3 hours, 70~73℃ for 1 hour, 75~78℃ for 4 hours, and the system was cooled down to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com