Preparation method of titanium dioxide pigment special for coating with high weather resistance

A technology of titanium dioxide and weather-resistant coatings, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problem that the coating film is not as dense as the alkaline silicon-coated film, the silicon film is not as compact as the product, and the weather resistance of the product is not as good and other problems, to achieve the effect of excellent hiding performance, excellent anti-powdering ability and excellent dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

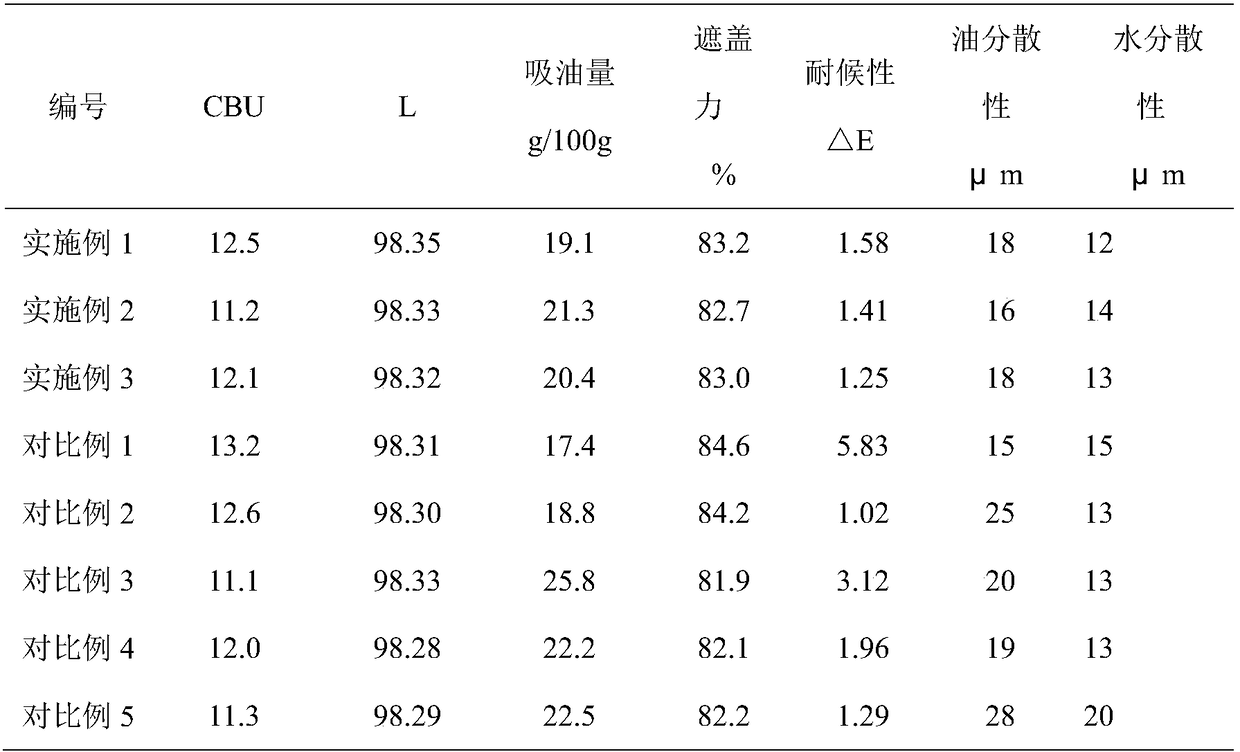

Examples

Embodiment 1

[0022] 1.1. Weigh 400g of the primary rutile titanium dioxide powder prepared by the chlorination method, add deionized water to prepare a slurry with a mass concentration of 20%, use a pH meter to detect the pH value of the slurry during the entire coating process, and use sodium hydroxide solution Adjust slurry pH to 9.5, add sodium silicate solution, the concentration of sodium silicate solution is SiO 2 Calculated as 100g / L, the amount of sodium silicate solution added is calculated as SiO in sodium silicate 2 accounted for TiO 2 0.2% by weight, aging for 20 minutes;

[0023] 1.2. Heat the ground slurry to 70°C, and maintain this temperature throughout the coating process;

[0024] 1.3. Evenly add 3.0% (as SiO 2 accounted for TiO 2 by weight) water-soluble sodium silicate solution, its concentration is SiO 2 Calculated at 100g / L, and at the same time, use a 5% sulfuric acid solution to maintain the pH value of the slurry at 10.5±0.2, and mature for 30 minutes to form ...

Embodiment 2

[0029] 1.1. Weigh 400g of the primary rutile titanium dioxide powder prepared by the chlorination method, add deionized water to prepare a slurry with a mass concentration of 30%, and use a pH meter to detect the pH value of the slurry in the entire coating process, and use potassium hydroxide solution Adjust slurry pH to 11.0, add potassium silicate solution, the concentration of potassium silicate solution is SiO 2 Calculated as 200g / L, the amount of potassium silicate solution added is calculated as SiO in potassium silicate 2 accounted for TiO 2 0.5% by weight, dispersed for 40 minutes;

[0030] 1.2. Heat the ground slurry to 90°C, and maintain this temperature throughout the coating process;

[0031] 1.3. Evenly add 5.0% water-soluble potassium silicate solution (as SiO2 accounted for TiO 2 weight), its concentration is SiO 2 Calculated at 200g / L, and at the same time, use a 10% nitric acid solution to maintain the pH value of the slurry at 9.0±0.2, and mature for 60 ...

Embodiment 3

[0036] 1.1. Weigh 400g of the primary rutile titanium dioxide powder prepared by the chlorination method, add deionized water to prepare a slurry with a mass concentration of 25%, use a pH meter to detect the pH value of the slurry during the entire coating process, and use sodium hydroxide solution Regulate slurry pH to 10.5, add sodium silicate solution, the concentration of sodium silicate solution is SiO 2 Calculated as 150g / L, the amount of sodium silicate solution added is the amount of SiO in sodium silicate 2 accounted for TiO 2 0.3% by weight, dispersed for 30 minutes;

[0037] 1.2. Heat the ground slurry to 80°C, and maintain this temperature throughout the coating process;

[0038] 1.3, Add 4.0% evenly within 100min (as SiO 2 accounted for TiO 2 by weight) water-soluble sodium silicate solution, its concentration is SiO 2 The calculated value is 150g / L, and at the same time, a 10% hydrochloric acid solution is used to maintain the pH value of the slurry at 10±0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com