Linear organic hole transport material and preparation and application thereof

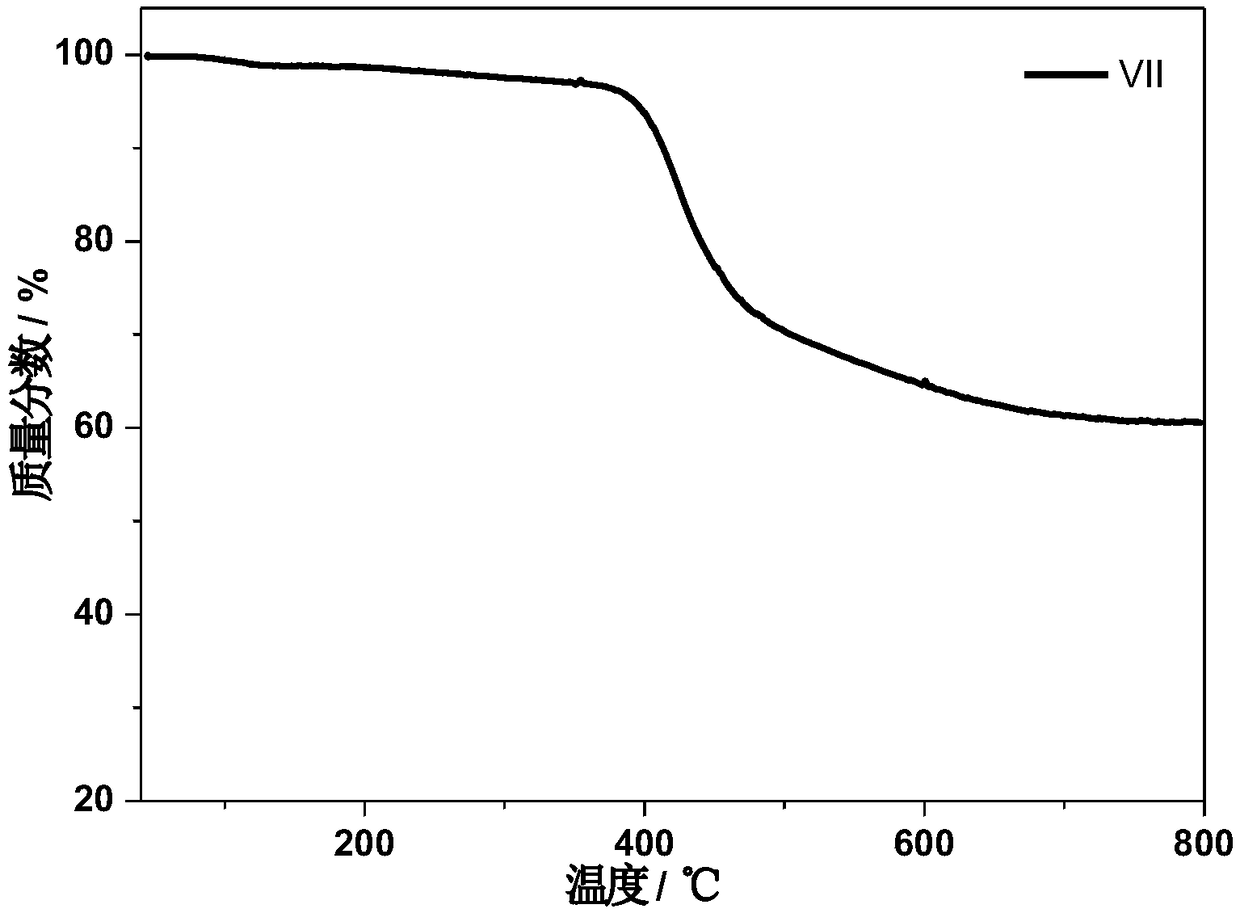

A hole transport material, organic technology, applied in the field of solar cells, to achieve excellent photothermal stability, improve efficiency, and good dissolution and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of above-mentioned linear organic hole transport material, its reaction formula is as follows:

[0050]

[0051]Compound I used in the present invention is based on literature Han, J.; Zheng, X.; Wang, Y.; Hu, L.Guo, C.; Wang, Y.; Li, Y.; Ma, D.; Qiao, W. ; Wang, Z.J.Mater.Chem.C, 2017, 5, 159-165 was prepared and synthesized; compound Ⅲ was synthesized according to literature Wang, Z.; Liang, M.; Tan, Y.; Ouyang, L.; Sun, Z.; Xue.S.J. Mater.Chem.A 2015,3,4865–4874; Compound VI was prepared according to literature Rakstys, K.; Abate, A.; IbrahimDar, M.; Gao, P.; Jankauskas, V.; Jacopin, G.; Kamarauskas , E.; Kazim, S.; Ahmad, S.; Prepared by M.; Nazeeruddi, M.K.J.Am.Chem.Soc.2015, 137, 16172-16178; other reagents were purchased.

Embodiment 1

[0053] A linear organic hole-transporting material has a chemical structural formula of the following formula (VII):

[0054]

[0055] The preparation method of above-mentioned linear organic hole transport material, its reaction formula is as follows:

[0056]

[0057] The above-mentioned linear organic hole transport material is prepared by the following steps:

[0058] Step 1, preparing compound I, compound III and compound VI, compound I according to literature Han, J.; Zheng, X.; Wang, Y.; Hu, L.Guo, C.; Wang, Y.; Li, Y. ; Ma, D.; Qiao, W.; Wang, Z.J.Mater.Chem.C, 2017, 5, 159-165 Preparation and synthesis; Compound Ⅲ according to literature Wang, Z.; Liang, M.; Tan, Y.; Ouyang, L .; Sun, Z.; Xue.S.J.Mater.Chem.A 2015,3, 4865–4874 prepared; compound Ⅵ according to literature Rakstys, K.; Abate, A.; IbrahimDar, M.; Gao, P.; Jankauskas , V.; Jacopim, G.; Kamarauskas, E.; Kazim, S.; Ahmad, S.; Prepared by M.; Nazeeruddi, M.K.J. Am. Chem. Soc. 2015, 137, 16172-16178...

Embodiment 2

[0069] A linear organic hole transport material, the difference from Example 1 is that step 2 is: under the conditions of argon protection and ice bath, add 20mL of anhydrous tetrahydrofuran to the reaction bottle as a solvent, add 2.19g of compound I and mix uniform, then 2mol / L lithium diisopropylamide solution was added dropwise to the reaction system; after the dropwise addition, the reaction solution continued to react for 1 h under ice bath; anhydrous copper chloride was added to the reaction system, the The ratio of compound I, lithium diisopropylamide and anhydrous copper chloride is 1:1.1:1.1. After keeping the reaction in ice bath for 1 hour, the reaction solution is slowly warmed up to room temperature for 8 hours; Quenched with ice water, extracted with ethyl acetate, dried over anhydrous magnesium sulfate, and evaporated under reduced pressure to remove the solvent; the crude product was purified by column chromatography (eluent: petroleum ether / dichloromethane=15 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com