Curing system for lime disinfection equipment

A disinfection equipment and curing technology, which is applied in the field of disinfection equipment, can solve problems such as splashing, potential safety hazards for operators, and high mixing requirements, and achieve the effects of reducing energy consumption, improving stability, and reducing the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

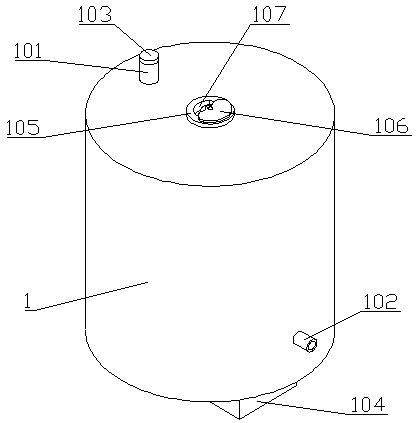

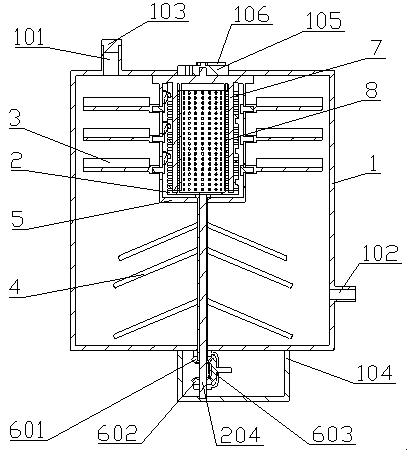

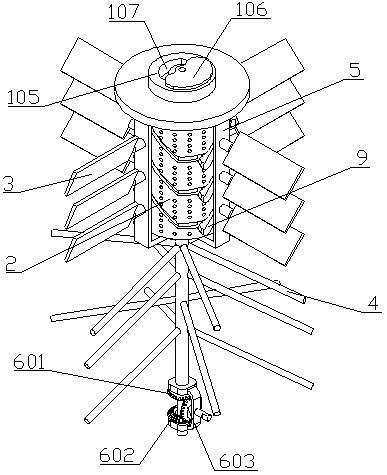

[0046] see Figure 1 to Figure 5 , the embodiment of the present invention provides a slaking system for lime disinfection equipment, which includes a cylinder 1, the axis of which coincides with the axis of the cylinder 1, and a stirring part that runs through the bottom wall of the cylinder 1, and is arranged on the stirring part The inner cylindrical aging filter cartridge 2 is arranged on the stirring part, and several scrapers 8 are slidingly matched with the inner side of the barrel wall of the aging filter cartridge 2, and the driving mechanism is arranged on the outer side of the bottom wall of the barrel body 1;

[0047] One side of the top of the cylinder body 1 is provided with a water inlet pipe 101 running through it, and the bottom of the other side of the cylinder body 1 opposite to the water inlet pipe 101 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com