Urban sludge pit reduction pretreatment method based on vacuum pre-pressing method

A vacuum pre-pressing method, a technology of municipal sludge, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc. The effect of improving bearing capacity and increasing drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

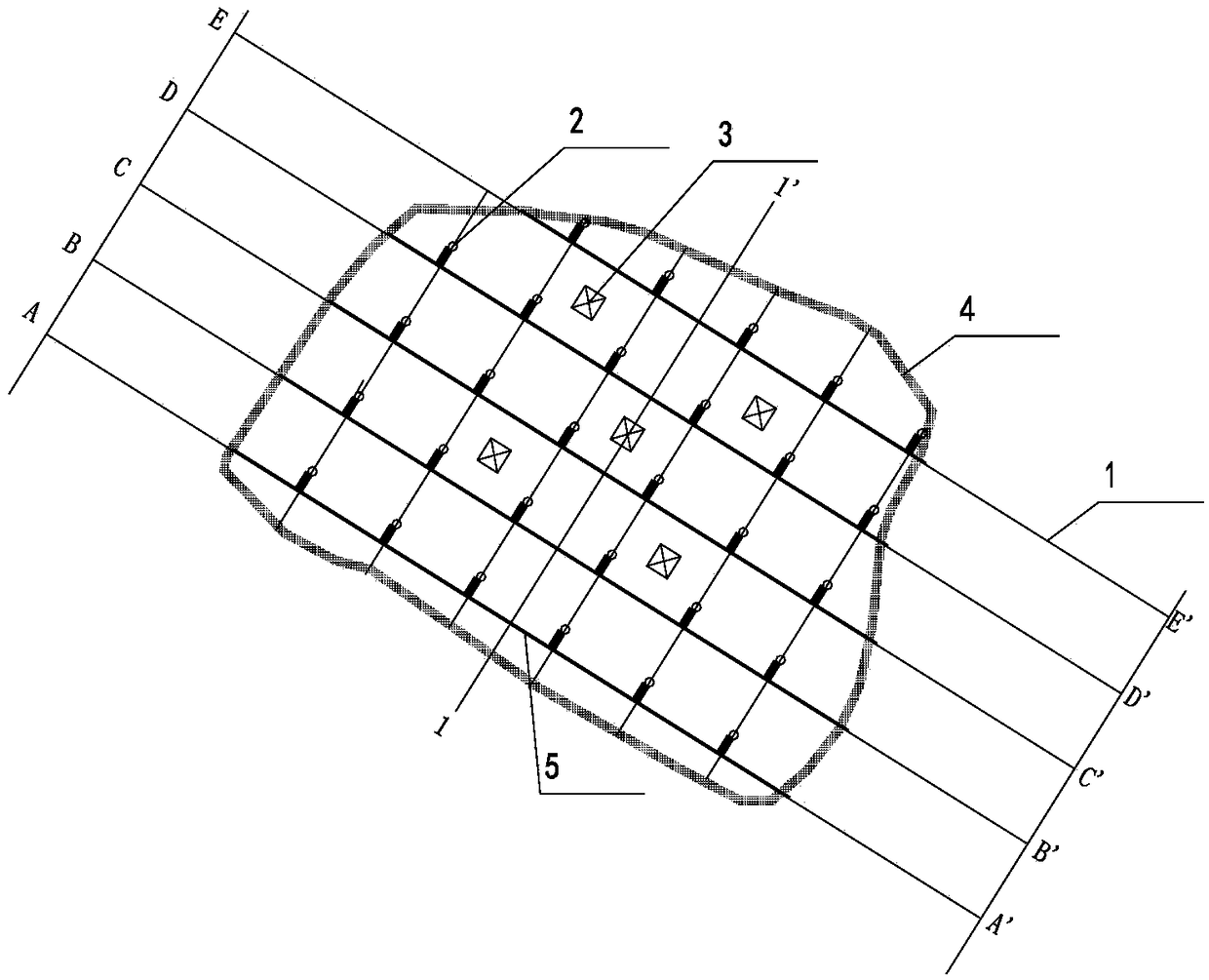

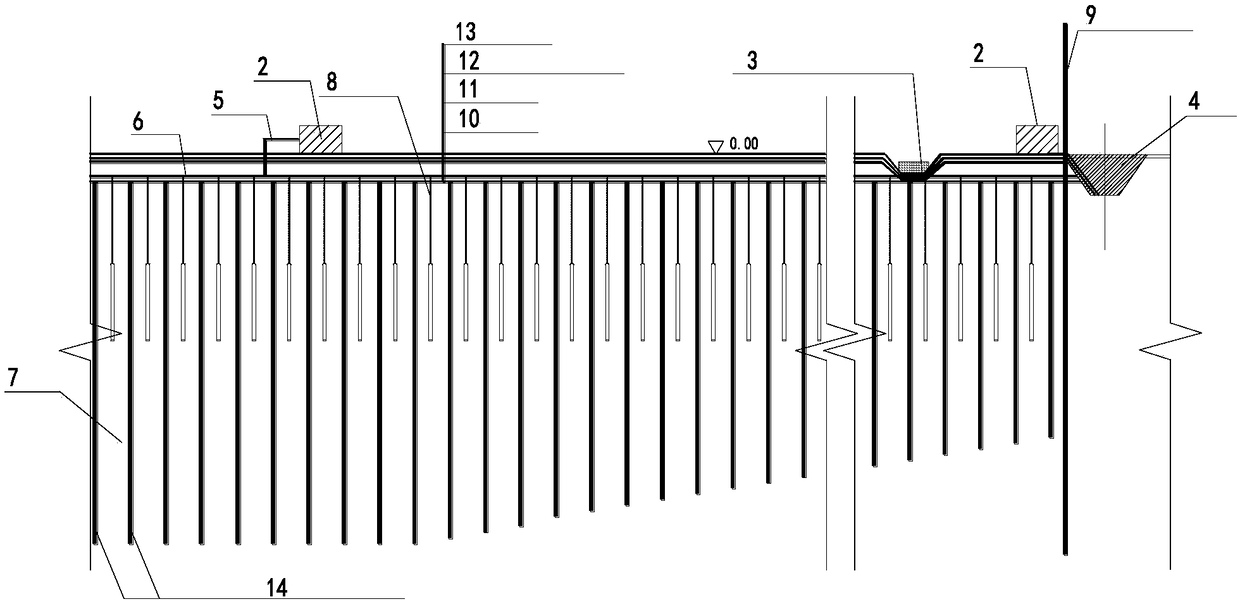

[0050] Such as Figure 1-8 As shown, a method of urban sludge pit reduction pretreatment based on vacuum preloading method, the construction steps are as follows:

[0051] (1) Woven geotextile 10 is laid on the surface of sludge 7;

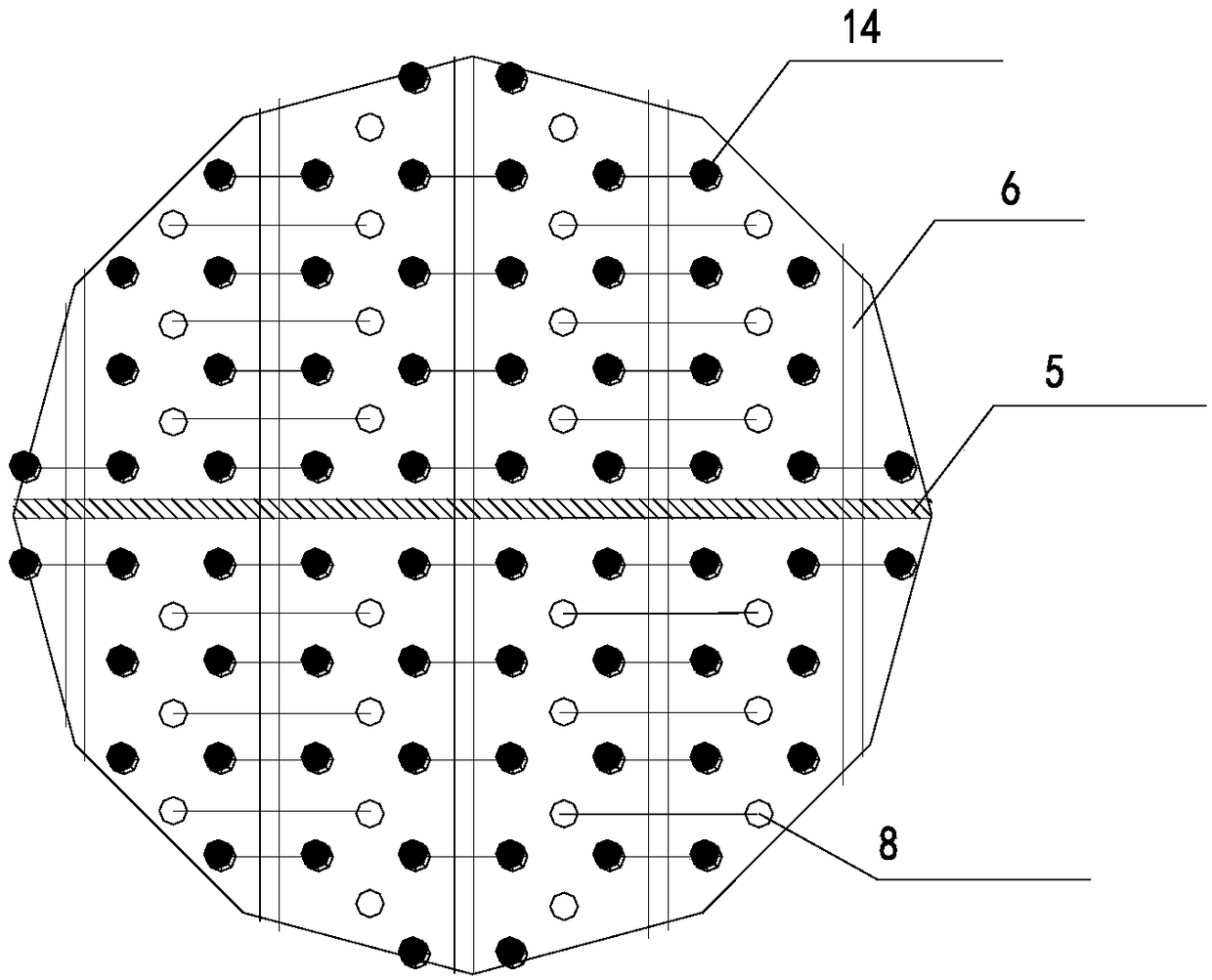

[0052] (2) vertical drainage body 14 (drainage board) is punched, and the head of the binding board is reserved; the surface of vertical drainage body 14 is smeared with active enzyme before entering;

[0053] (3) Lay the vacuum main pipe 5 and the filter pipe 6. The vacuum main pipe 5 and the filter pipe are arranged orthogonally. A filter pipe 6 is arranged between every two rows of vertical drainage bodies 14. The two sides of the filter pipe 6 are respectively connected to the adjacent reserved The head of the board is bound and connected; a vacuum main pipe 5 perpendicular to the filter pipe 6 is set every 20-30m;

[0054] (4) Set up active drainage bag 8, drainage bag 8 exposes the enough length of sludge surface to tie up with filter pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com