Invisible glass shaping method

A technology of glass and quartz glass, which is applied in the direction of chemical instruments and methods, glass/slag layered products, coatings, etc., which can solve the problem of not being able to meet the requirements of equipment, the inability to meet the stealth characteristics of multi-base station radars, and the reduction of visible light transmission characteristics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The application will be further described in detail below with reference to the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the related invention, but not to limit the invention. In addition, it should be noted that, for ease of description, only the parts related to the relevant invention are shown in the drawings.

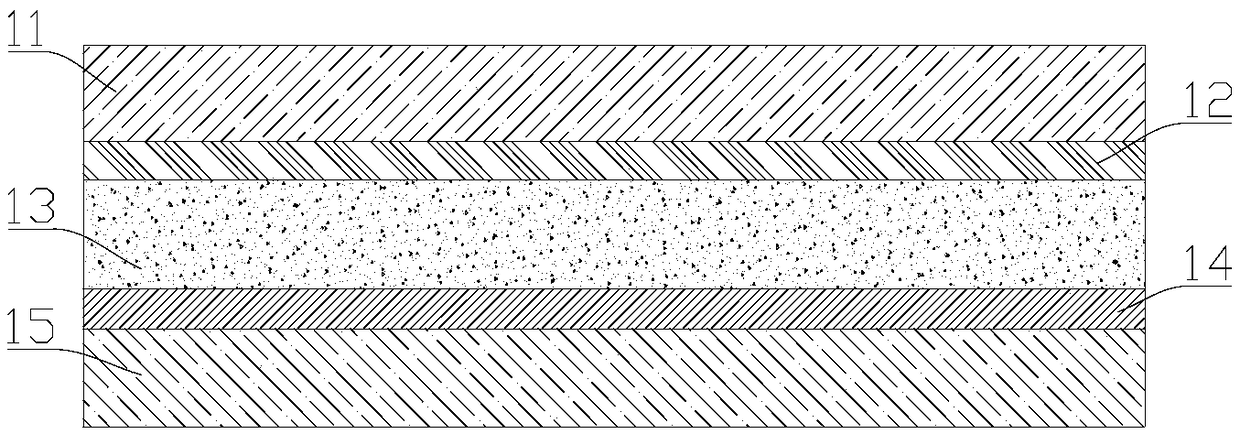

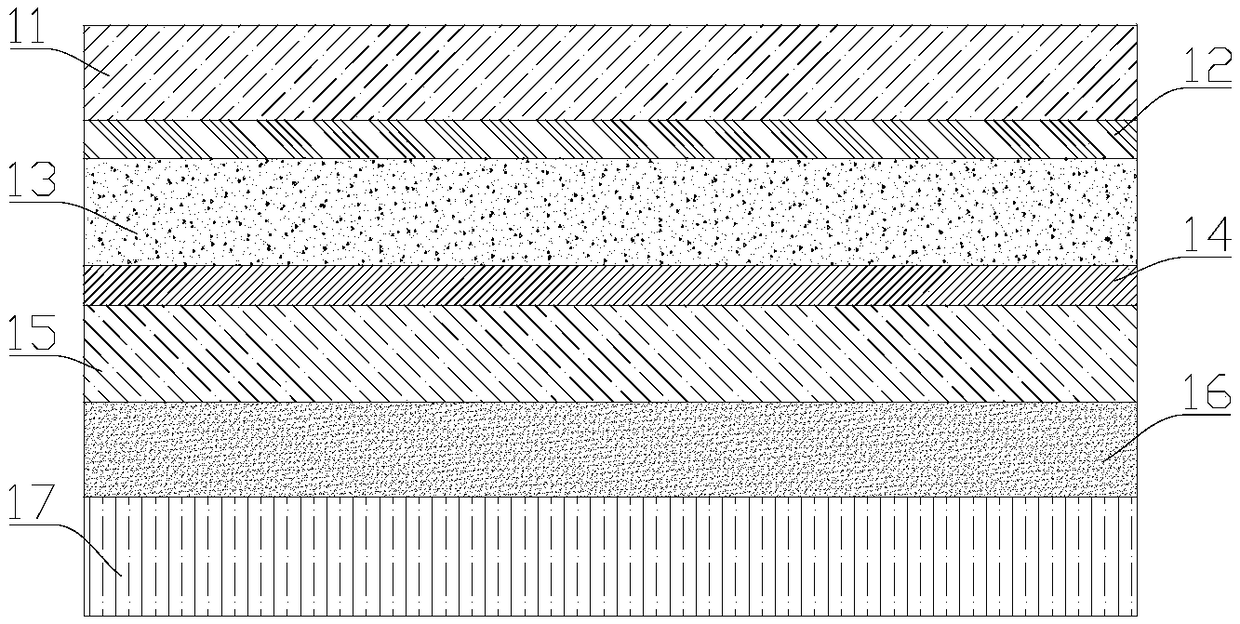

[0035] figure 1 It is a schematic cross-sectional view of the stealth glass provided by the embodiment of the present application. Such as figure 1 As shown, the stealth glass provided by the embodiment of the present application includes a first protective layer 11 on the outer side, a second protective layer 15 on the inner side, and a metamaterial sandwiched between the first protective layer 11 and the second protective layer 15. The structural layer 12, the first transition layer 13, and the radar wave reflection layer 14. The foregoing various layer structures are all light-trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com