Vacuum electron beam welding method for special-shaped complex large-thickness fuel loading bin

A vacuum electron beam and electron beam welding technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult to achieve 8-10mm thick joint welding, difficult to control deformation, softening of heat affected zone, etc. , to achieve the effect of improving welding quality, preventing sag, and improving weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and example, the invention is described further.

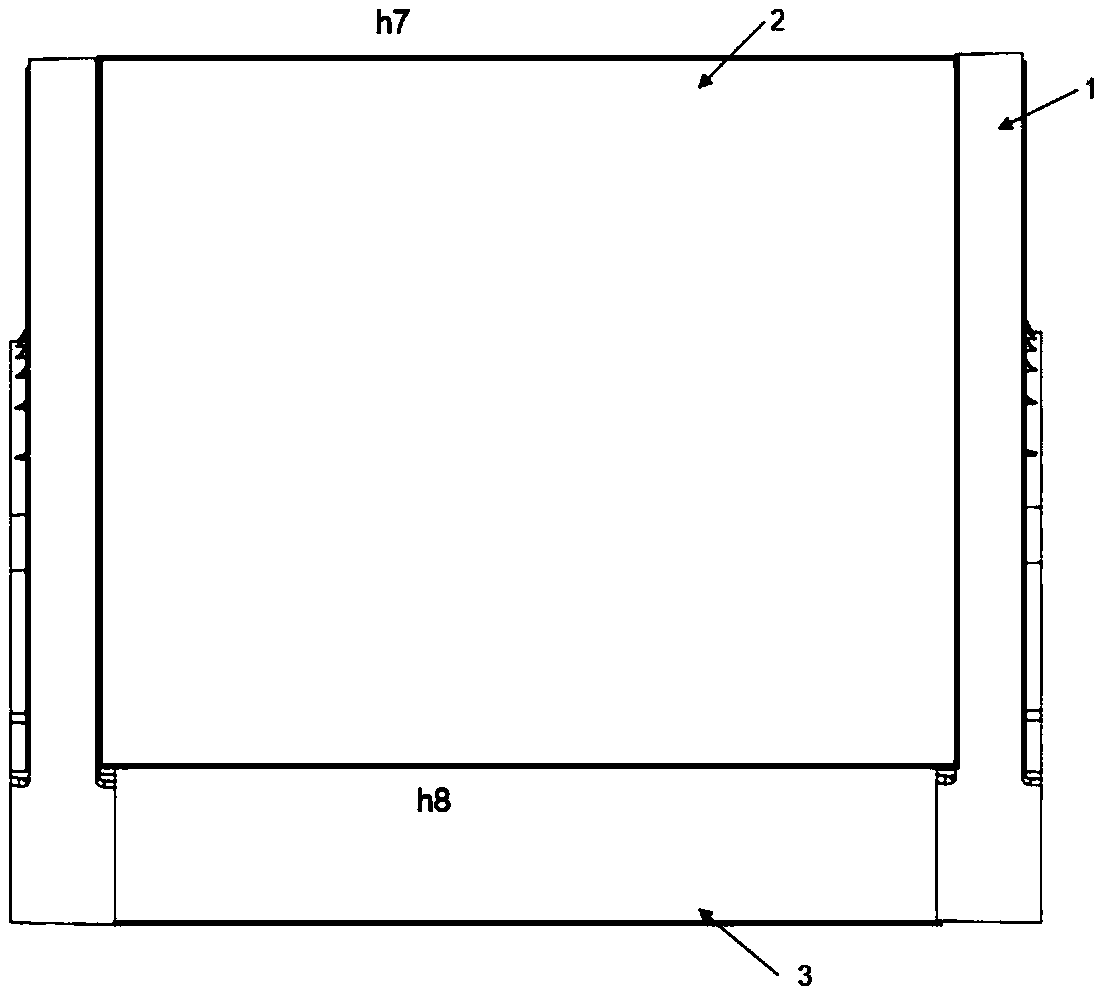

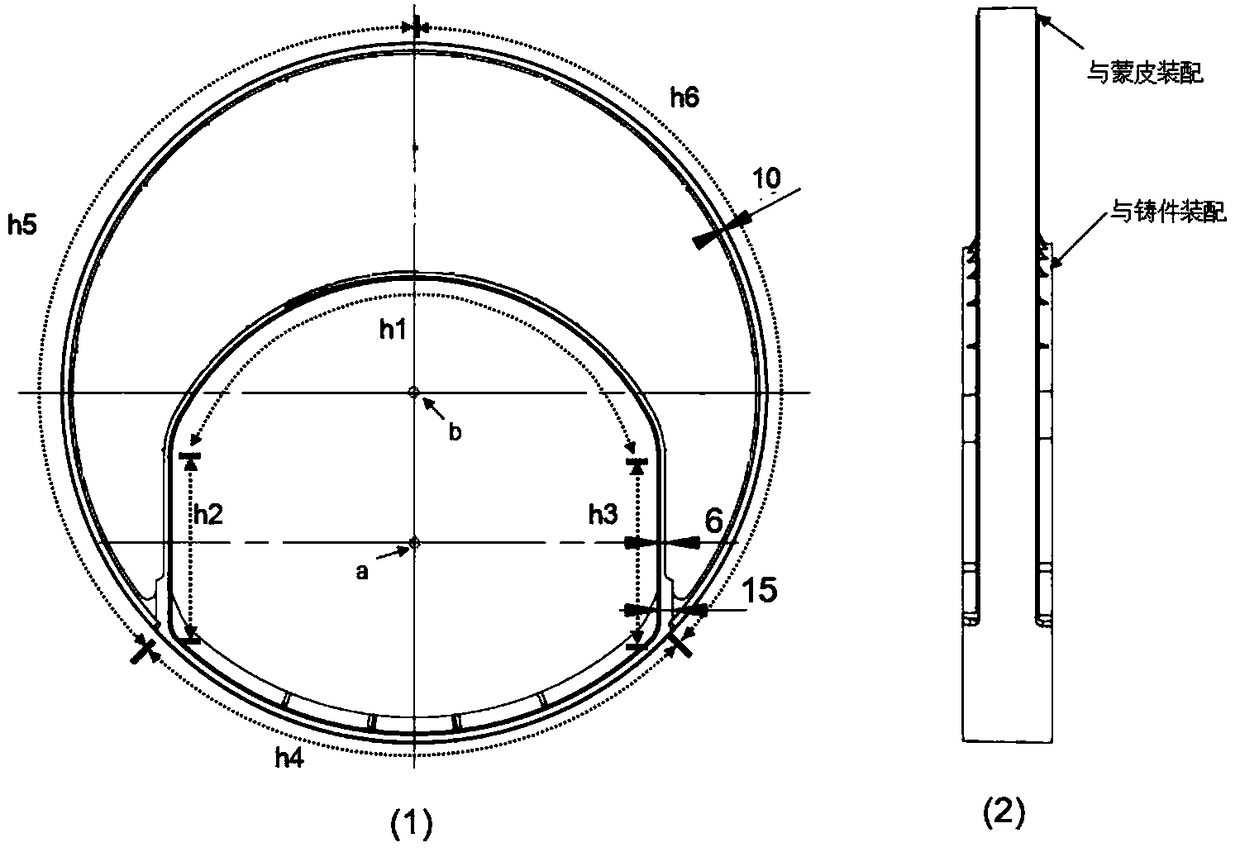

[0043] Taking an aircraft fuel tank as an example ( figure 1 ), consisting of 2 end frames, 1 casting and 2 skins. The material of the casting is ZL114A aluminum alloy, and the material of the end frame and skin is 5A06 aluminum alloy. The total length of the fuel tank is 1100mm, the diameter is 900mm, and the maximum thickness of the welded joint is 15mm.

[0044] Concrete implementation plan carries out according to the following steps:

[0045] Step 1: Preparation before welding;

[0046] Pickle the end frame and skin of the fuel tank to remove surface oil and oxide film, and dry it at 50-80°C for 20-30min. Use a wire brush to polish the end frame, skin and the casting area to be welded to a bright metallic luster, and wipe it clean with acetone;

[0047] Step 2: End frame and casting welding assembly;

[0048] Use the welding tool to assemble the two end frames an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com