TiB2 reinforced aluminum alloy powder for additional material manufacturing and preparation method thereof

A technology of additive manufacturing and aluminum alloy, which is applied in the field of preparation of TiB2 reinforced aluminum alloy powder, can solve problems such as low strength, low mechanical properties, and complex design, and achieve the goals of improving powder performance, shortening the preparation process, and reducing preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

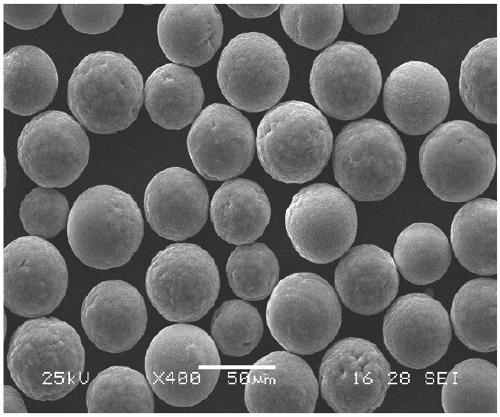

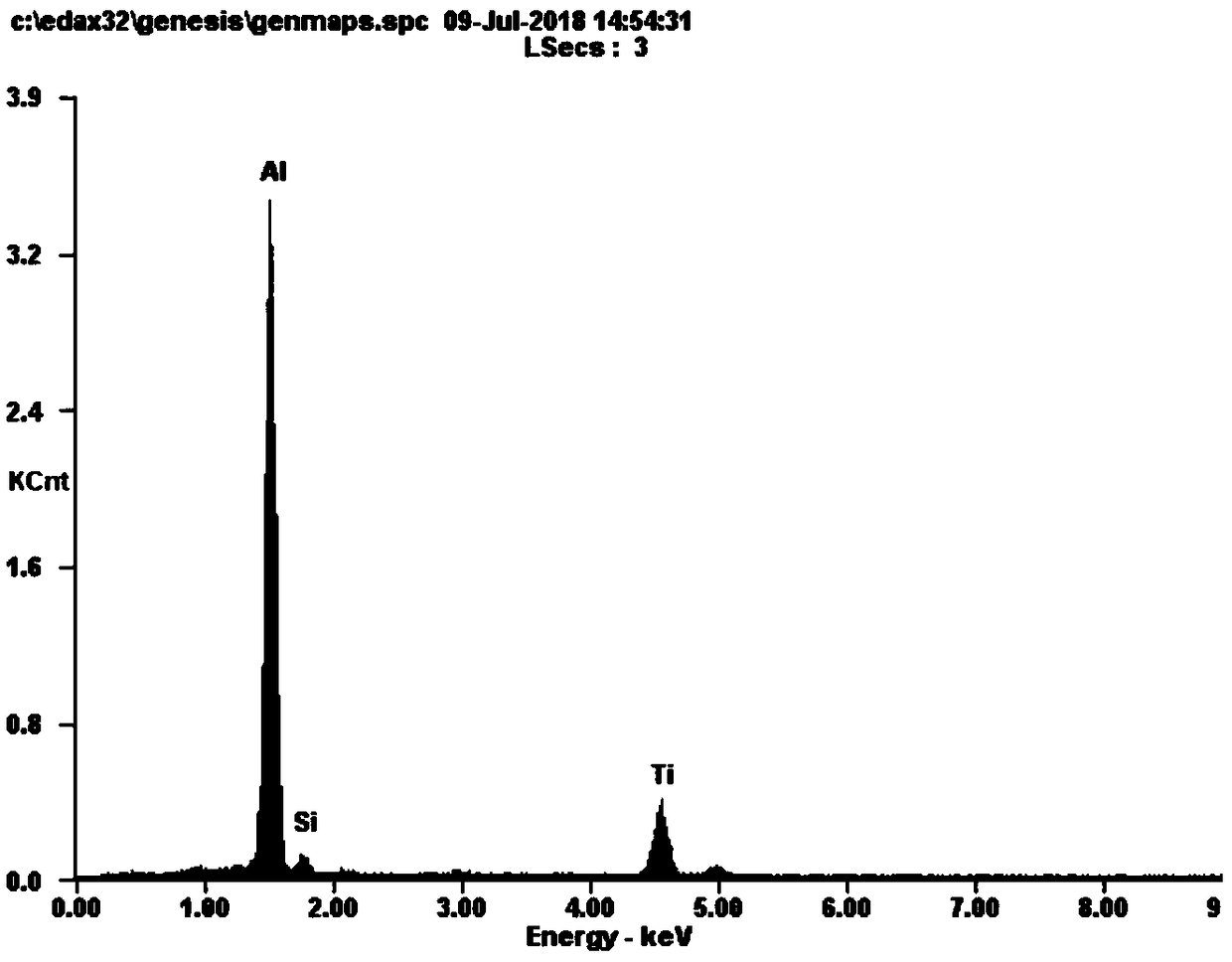

[0035] a. 97g of AlSi 10 Mg powder and 3g of TiB 2 powder mixed together, where TiB 2 The powder purity is 99.5%, the particle size range is 0-5μm, and the average particle size is 1.5μm; AlSi 10 The particle size range of Mg powder is 20-60μm, d 50 It is 42μm, the fluidity is 70s / 50g, and the sphericity is 90%.

[0036] b. Set the mass ratio of ball to material to 3:1, and 300g of grinding balls (by and The composition of the ball) is mixed with the mixed powder and put into a ball mill for ball milling. The overall ball milling time is 14 hours, and the ball milling speed is 200r / min.

[0037] By this method, TiB-containing 2 AlSi 10 The tensile strength of the Mg composite material powder can reach 530MPa by testing the universal mechanical testing machine.

Embodiment 2

[0039] a. 95g of AlSi 10 Mg powder and 5g of TiB 2 powder mixed together, where TiB 2 The powder purity is 99.6%, the particle size range is 0-5μm, and the average particle size is 2μm; AlSi 10 The particle size range of Mg powder is 20-60μm, d 50 It is 44μm, the fluidity is 68s / 50g, and the sphericity is 91%.

[0040] b. Set the mass ratio of ball to material to 4:1, mix 400g of balls with the mixed powder, put them into a ball mill for ball milling, and fill with argon gas for protection during the ball milling process. The overall ball milling time is 16 hours, and the ball milling speed is 350r / min.

[0041] Argon protection is filled during ball milling, which can effectively prevent the oxidation reaction of the aluminum alloy during the ball milling process, and the TiB thus prepared 2 Reinforced aluminum alloy powder, the tensile strength can reach 535MPa.

Embodiment 3

[0043] a. 94g of AlSi 10Mg powder and 6g of TiB 2 powder mixed together, where TiB 2 The powder purity is 99.7%, the particle size range is 0-5μm, and the average particle size is 2.5μm; AlSi 10 The particle size range of Mg powder is 20-60μm, d 50 It is 45μm, the fluidity is 63s / 50g, and the sphericity is 93%.

[0044] b. Set the mass ratio of ball to material to 5:1, put 500g of grinding balls (by and The grinding ball composition) is mixed with the mixed powder, and 0.5 parts by weight of stearic acid is added to the mixed powder as a process control agent, and they are put into a ball mill together for ball milling, and nitrogen protection is filled in the ball milling process. The overall ball milling time 18h, ball milling speed 450r / min.

[0045] Adding stearic acid into the mixed powder as a process control agent can prevent the excessive agglomeration of the aluminum alloy powder during the ball milling process, and the prepared TiB 2 Reinforced aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com