Ozone and urea integrated desulfurization and denitrification device and desulfurization and denitrification method

A desulfurization and denitrification, ozone technology, applied in the direction of chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of secondary pollutants, short survival time of free radicals, and increase the cost of denitrification, so as to save operating costs and achieve excellent denitrification Effect, the effect of saving denitrification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

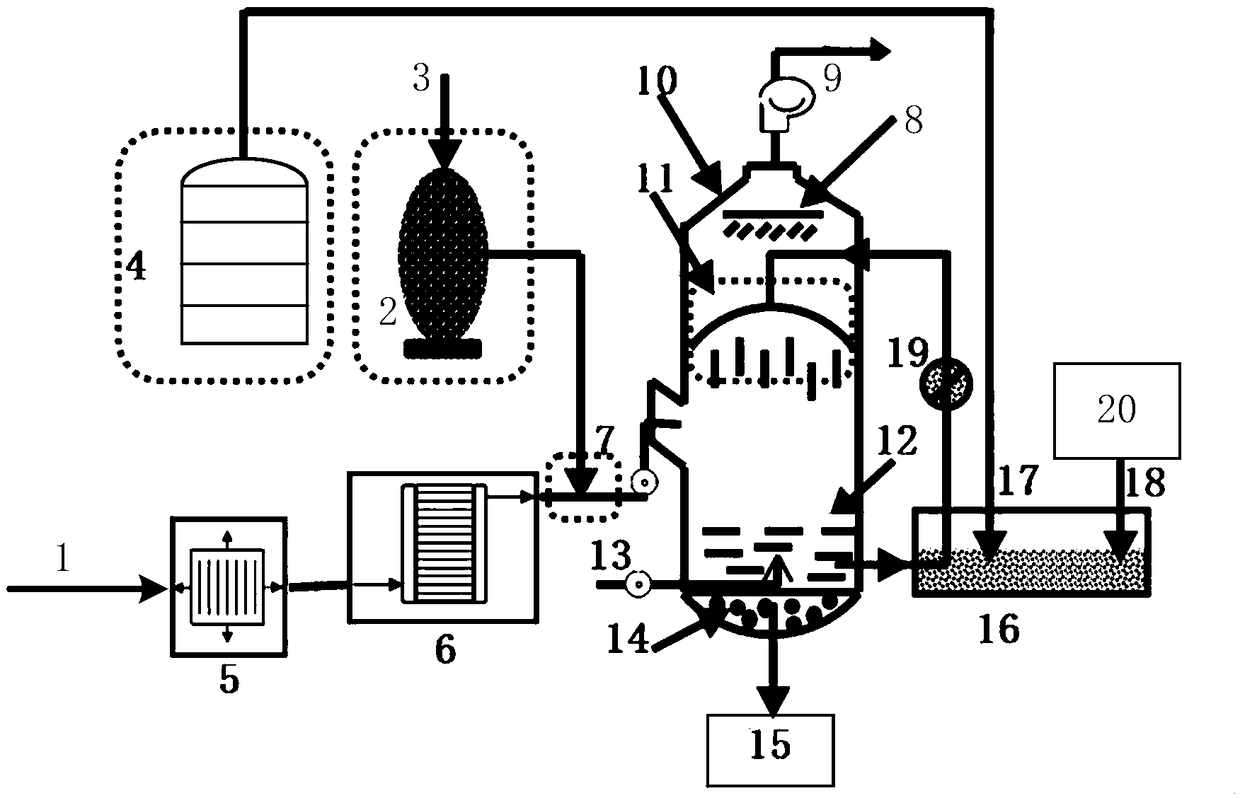

[0026] Such as figure 1 As shown, the integrated desulfurization and denitration device of ozone combined with urea includes a flue gas transmission pipeline 1, a urea storage tank 4, an air preheater 5, an electrostatic precipitator 6, an ozone injection device 7 (that is, an ozone mixed oxidation reactor), Ozone generator 8, desulfurization and denitrification tower 10, slurry storage tank 16, circulation pump 19 and tail flue 9.

[0027]The input port of the air preheater 5 is connected with the smoke outlet of the flue gas transmission pipe 1 . The output port of the air preheater 5 is connected with the input port of the electrostatic precipitator 6 . The output port of the electrostatic precipitator 6 communicates with the flue gas input port of the ozone injection device 7 . A nitric oxide concentration detection sensor is arranged in the pipeline between the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com