Multilens integration component for low temperature application

A low-temperature application, multi-lens technology, applied in optical components, installation, optics, etc., can solve the problems of difficult to guarantee assembly accuracy, large workload of multi-lens assembly, etc., to achieve high assembly efficiency, prevent optical crosstalk, and implement simple effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

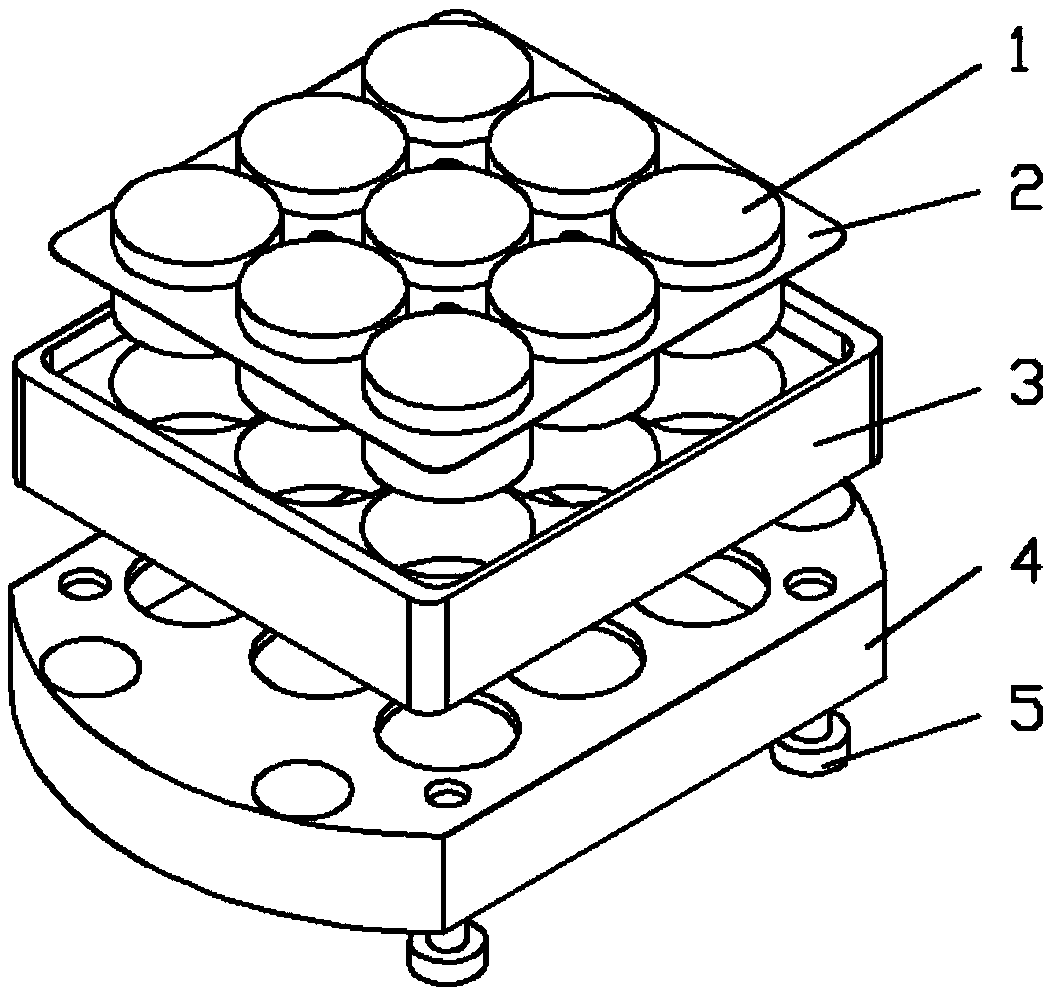

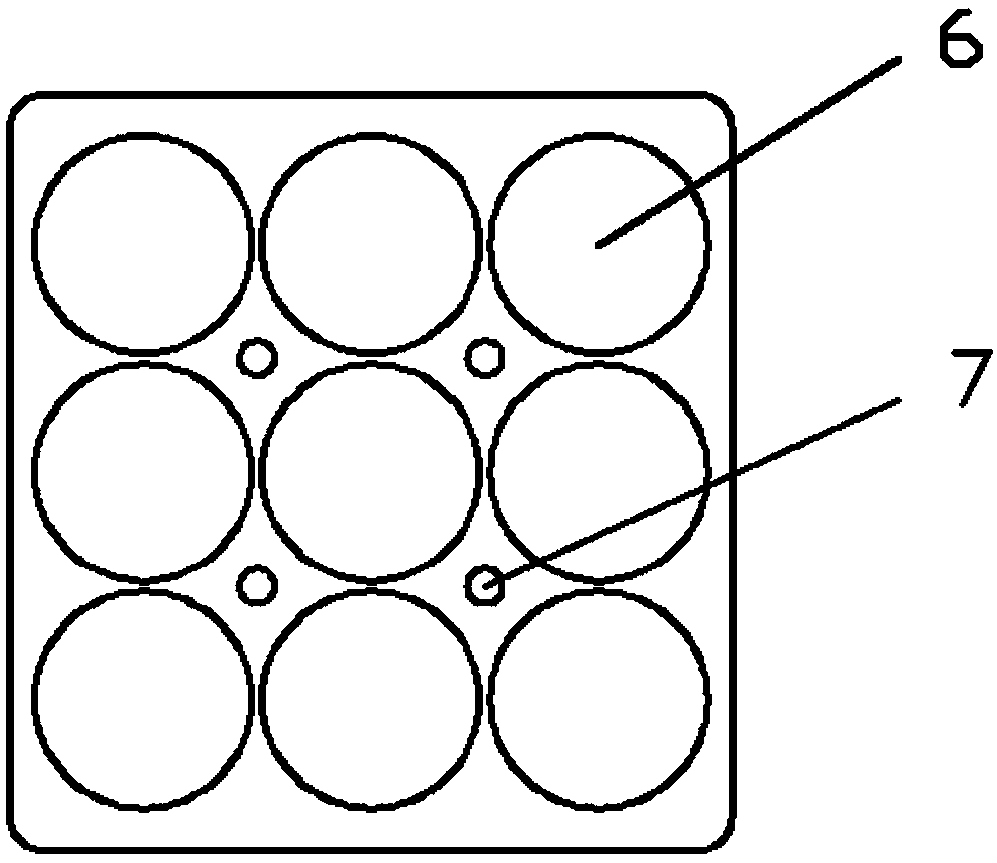

[0014] The present invention provides a specific application example of a multi-lens integrated assembly for low temperature applications, see figure 1 , figure 2 , including lens group array 1, horizontal positioning sheet 2, spacer block 3, lens holder 4 and other parts. The material of the lens group is germanium, and the array size is 3×3. In order to match the expansion coefficient of germanium, the horizontal positioning plate 2, spacer block 3, and lens holder 4 are all processed by Kovar alloy, and the outer surface is blackened. The horizontal positioning sheet 2 is a thin sheet with a thickness of 0.1 mm. It is processed once by chemical etching to ensure the machining accuracy of the aperture and the holes. The horizontal positioning sheet 2 is provided with lens positioning holes 6 arranged in a 3×3 array. The arrangement rules are consistent with the arrangement rules of the lens array, the diameter of each lens positioning hole 6 is 0.02mm larger than the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com