Preparation method and application of macrolide antibiotic sensor based on iron nitride

A technology of macrolides and antibiotics, applied in chemiluminescence/bioluminescence, analysis by making materials undergo chemical reactions, instruments, etc., can solve the problems of reduced sensitivity of electrochemical sensors, limitations on the application of molecularly imprinted membranes, stability and Reduced reproducibility and other issues, to achieve excellent electron transfer capabilities, lower detection costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of FeN-nanoarray

[0031] (1) Use dilute hydrochloric acid, absolute ethanol and deionized disposable electrode for ultrasonic cleaning to remove the oxide layer and surface impurities of the disposable electrode;

[0032] (2) Weigh 1 mmol iron nitrate hexahydrate Fe(NO 3 ) 3 ·6H 2 O and 3 mmol urea CO(NH 2 ) 2 , put it into a 50 mL beaker, add 30 mL of deionized water and stir until clear, then transfer to a 50 mL polytetrafluoroethylene reactor;

[0033] (3) Put the disposable disposable electrode treated in step (1) into the solution in the reaction kettle in step (2), and react at a temperature of 100°C for 12 hours to prepare the iron hydroxide nanosheet array precursor body electrode;

[0034] (4) Insert the iron hydroxide nanosheet array precursor electrode obtained in step (3) into ammonia water for 5 seconds and then take it out, heat it to 340°C in ammonia environment and keep it for 8 hours, then continue to naturally Cool down to...

Embodiment 2

[0036] Example 2 Preparation of FeN-nanoarray

[0037] (1) Use dilute hydrochloric acid, absolute ethanol and deionized disposable electrode for ultrasonic cleaning to remove the oxide layer and surface impurities of the disposable electrode;

[0038] (2) Weigh 2 mmol iron nitrate hexahydrate Fe(NO 3 ) 3 ·6H 2 O and 6 mmol urea CO(NH 2 ) 2 , put it into a 50 mL beaker, add 30 mL of deionized water and stir until clear, then transfer to a 50 mL polytetrafluoroethylene reactor;

[0039] (3) Put the disposable disposable electrode processed in step (1) into the solution in the reaction kettle in step (2), and react at a temperature of 110°C for 11 hours to prepare the iron hydroxide nanosheet array precursor body electrode;

[0040] (4) Insert the iron hydroxide nanosheet array precursor electrode obtained in step (3) into ammonia water for 15 seconds and then take it out, heat it to 370°C and keep it for 6 hours in an ammonia environment, then continue to naturally Cool d...

Embodiment 3

[0042] Example 3 Preparation of FeN-nanoarray

[0043] (1) Use dilute hydrochloric acid, absolute ethanol and deionized disposable electrode for ultrasonic cleaning to remove the oxide layer and surface impurities of the disposable electrode;

[0044] (2) Weigh 3 mmol iron nitrate hexahydrate Fe(NO 3 ) 3 ·6H 2 O and 9 mmol urea CO(NH 2 ) 2 , put it into a 50 mL beaker, add 30 mL of deionized water and stir until clear, then transfer to a 50 mL polytetrafluoroethylene reactor;

[0045] (3) Put the disposable disposable electrode treated in step (1) into the solution in the reaction kettle in step (2), and react at a temperature of 130°C for 9 hours to prepare the iron hydroxide nanosheet array precursor body electrode;

[0046] (4) Insert the iron hydroxide nanosheet array precursor electrode obtained in step (3) into ammonia water for 30 seconds and take it out. In the ammonia environment, heat to 400°C and keep it for 4 hours, then continue to naturally Cool down to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

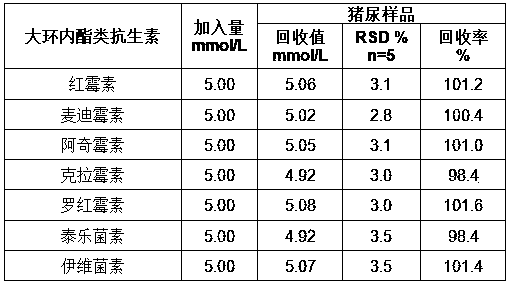

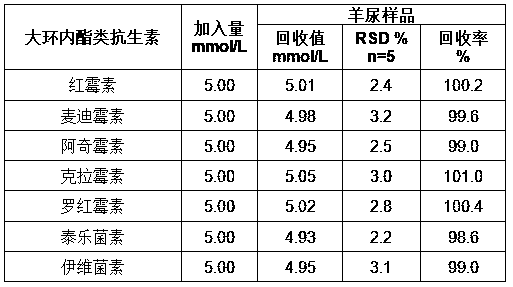

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com