Waterproof coil material with high elongation, and preparation method thereof

A waterproof membrane and elongation technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of unreachable, low seam peeling strength, low elongation, etc., reduce stress concentration points, and have remarkable waterproof performance , High impermeability effect

Inactive Publication Date: 2019-01-22

马鞍山市永固防水科技有限公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, the asphalt waterproofing membrane still has the problem of low elongation, and the maximum strength when the membrane overlaps with the membrane is torn, that is, the seam peeling strength is low, which cannot meet the high requirements of roads and bridges. Occasion requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

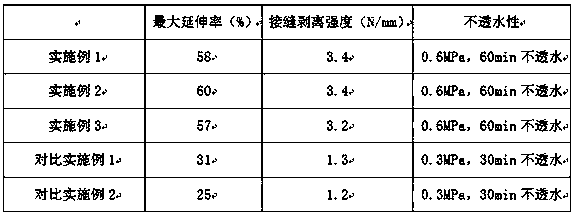

Login to View More Abstract

The invention discloses a waterproof coil material with high elongation, and a preparation method thereof. According to the present invention, the prepared waterproof coil material has high elongationand high seam peeling strength, can be used in construction environments with high requirements, and further has high water impermeability and significant water resistance; by modifying nanometer magnesium oxide and nanometer titanium dioxide with peach gum powder and Shellac, the compatibility of the nanometer inorganic filler and the substrate is enhanced, the uniform dispersion is easily achieved, the stress concentration points are reduced, and the elongation and the seam peeling strength of the target material are improved; and by re-modifying the nanometer inorganic filler with the titanate coupling agent and the polyurethane emulsion, the dispersibility and the compatibility of the filler are further enhanced while the water resistance of the inorganic filler is enhanced so as to improve the waterproof performance of the target material.

Description

technical field The invention belongs to the technical field of waterproof coiled material, in particular to a waterproof coiled material with relatively high elongation and a preparation method thereof. Background technique Elastomer-modified asphalt waterproofing membranes are mainly used for waterproofing of roofs, basements, toilets, bridges, swimming pools and other buildings in various buildings. Japan and the United States also use elastomer-modified asphalt waterproofing membranes. Elastomer-modified asphalt waterproofing membranes The material has become the first material for waterproofing projects, which not only changes the urban landscape, but also improves the drainage and heat insulation performance of the roof. The high-performance elastomer-modified asphalt waterproofing membrane has become a national key development product. However, at present, the asphalt waterproofing membrane still has the problem of low elongation, and the maximum strength when the me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L95/00C08L11/00C08K9/04C08K3/22C08K5/13

CPCC08K2003/222C08K2003/2241C08K2201/011C08L95/00C08L2205/025C08L2205/035C08L11/00C08K9/08C08K9/04C08K3/22C08K5/13

Inventor 赵庆亮

Owner 马鞍山市永固防水科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com