A kind of anti-high overload composite propellant and preparation method thereof

A propellant and oxidant technology, applied in offensive equipment, explosives processing equipment, explosives, etc., can solve the problem that composite propellants cannot meet the needs of use, and achieve the effect of improving anti-overload performance, ensuring work safety, and reducing the degree of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The formula of this embodiment: HTPB, mass content is 8%; Ammonium perchlorate, mass content is 60%; RDXG, mass content is 18%; Aluminum powder, mass content is 6%; Diisocyanate , with a mass content of 3%; triethanolamine; with a mass content of 2%, and dibutyl phthalate, with a mass content of 3%. The composition of raw materials is as follows: HTPB 192.4g, ammonium perchlorate 1443g, RDX 432.9g, aluminum powder 144.3g, diisocyanate 72.15g, triethanolamine 48.1g, dibutyl phthalate 72.15g.

[0031] The preparation method is as follows:

[0032] Step 1, weighing and obtaining corresponding raw materials;

[0033] Step 2: Mix the above raw materials, stir evenly, and stir at a temperature of 50°C to 60°C to obtain a propellant slurry;

[0034] Step 3. Vacuum pouring: pour the propellant slurry into the medicine mold or the engine casing, and the pouring time is not less than 80 minutes;

[0035] Step 4. Curing: heat and cure the mold or the engine housing containing t...

Embodiment 2

[0041] The formula of this embodiment: HTPB, mass content is 8.5%; Ammonium perchlorate, mass content is 57%; Octogen, mass content is 15%; Aluminum powder, mass content is 16.5%; Diisocyanate Esters, with a mass content of 1%; triethanolamine, with a mass content of 1%, and dioctyl adipate, with a mass content of 1%. The composition of raw materials is as follows: HTPB 205.5g, ammonium perchlorate 1376.5g, Octogen 362.5g, aluminum powder 398.5g, diisocyanate 24g, triethanolamine 24g, dioctyl adipate 24g.

[0042] The preparation method is the same as in Example 1.

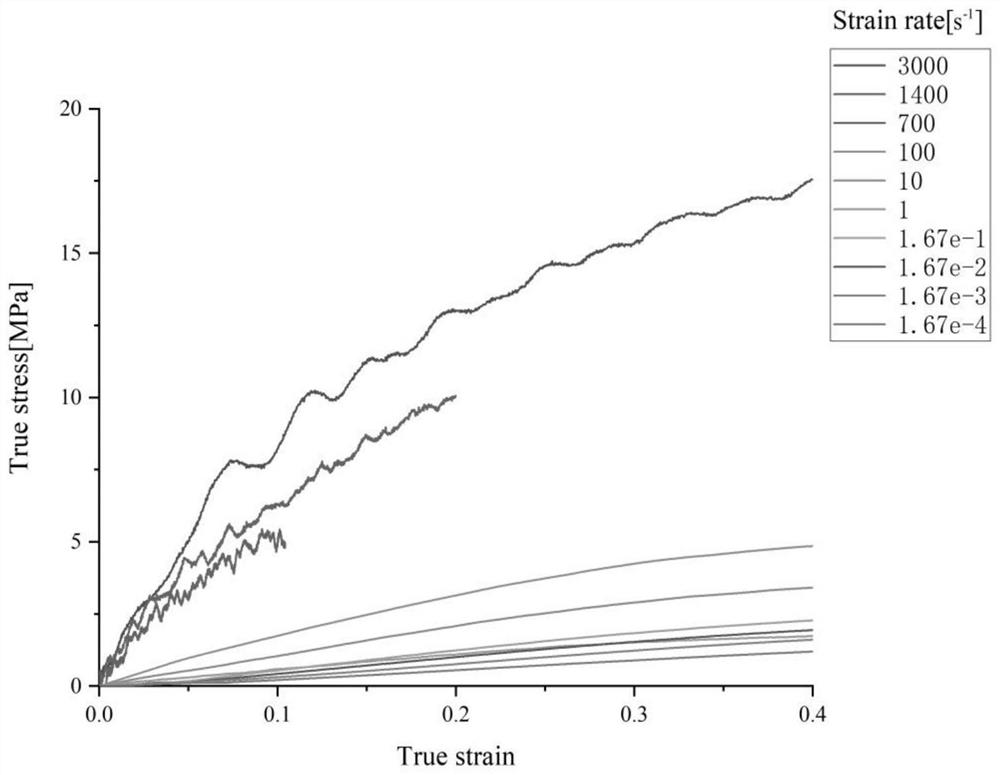

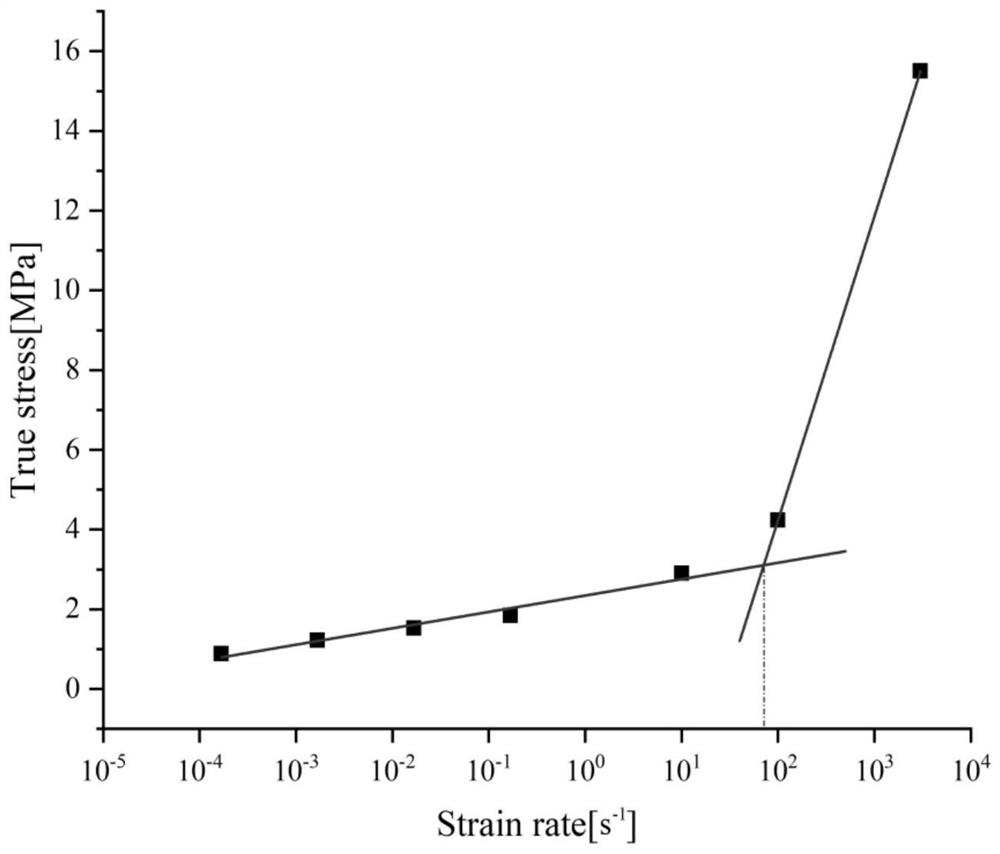

[0043] The propellant grain obtained in this example has a maximum axial strain of about 0.23 and a maximum strain rate of about 3s under a high overload of 12000g -1 . The maximum radial displacement of a point on the outer diameter of the bottom end surface is about 0.27mm, and the propellant grain obtained in this embodiment is capable of resisting a high overload of 12000g.

Embodiment 3

[0045] The formula of this embodiment: HTPB, mass content is 8%; Ammonium perchlorate, mass content is 54.5%; RDX, mass content is 19%; Aluminum powder, mass content is 10%; Diisocyanate , with a mass content of 4%; triethanolamine; with a mass content of 2%, and dioctyl sebacate, with a mass content of 2.5%. The composition of raw materials is as follows: HTPB 192g, perchloric acid 1308.5g, RDX 456.2g, aluminum powder 240g, diisocyanate 96g, triethanolamine 48g, dioctyl sebacate 60g.

[0046] The preparation method is the same as in Example 1.

[0047] The propellant grain obtained in this example has a maximum axial strain of about 0.22 and a maximum strain rate of about 4s under a high overload of 12000g -1 . The maximum radial displacement of a point on the outer diameter of the bottom end surface is about 0.3 mm, and the propellant grain obtained in this embodiment is capable of resisting a high overload of 12000 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com