Adsorbent for extracorporeal blood circulation to remove LDL, preparation method thereof, and perfusion device

An adsorbent and external circulation technology, which is applied to suction devices, chemical instruments and methods, other chemical processes, etc., can solve the problems of high metal ion adsorption rate, high antibody cost, low adsorption rate, etc. Specific adsorption, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take 20mL of polyacrylic acid carrier resin, use epichlorohydrin or 1,4-butanediol diglycidyl ether for epoxidation, control the pH at 8 to 11, and react at 30°C for 3 hours to obtain the epoxidized carrier , the epoxidized carrier was purified to neutral pH with purified water. Mix the epoxidized support with the aminating agent at a volume ratio of 1: (2 to 6), and react at 30°C for 1.5 hours to aminate the support. The aminating agent includes ammonia water, ethylenediamine, 1,2 - propylenediamine or 1,3-propylenediamine. The carrier was washed and purified to neutral pH using purified water. Mix the aminated carrier with polyacrylic acid and EEDQ at a mass ratio of 10:0.2:0.1, control the pH to 3 to 7, react at room temperature for 12 hours, immobilize the polyacrylic acid ligand on the carrier, and clean and purify the adsorbent. Obtain LDL adsorbent.

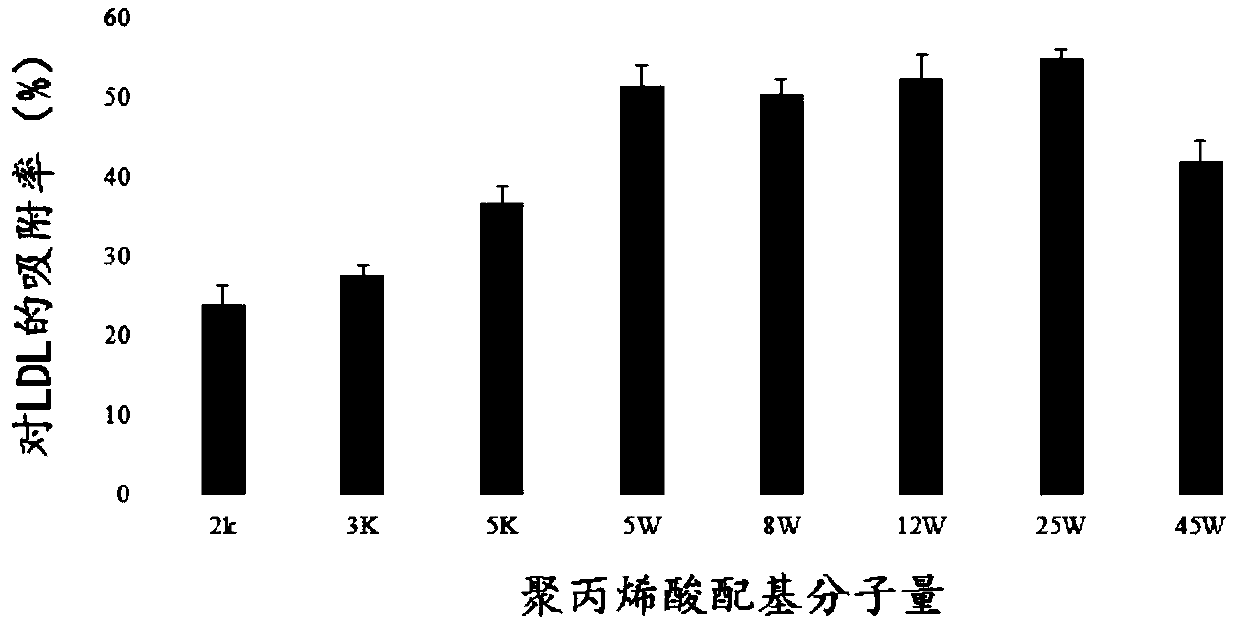

[0043] Using polyacrylic acid ligands with different molecular weights (2,000 to 450,000, that is, 2k to 45w),...

Embodiment 2

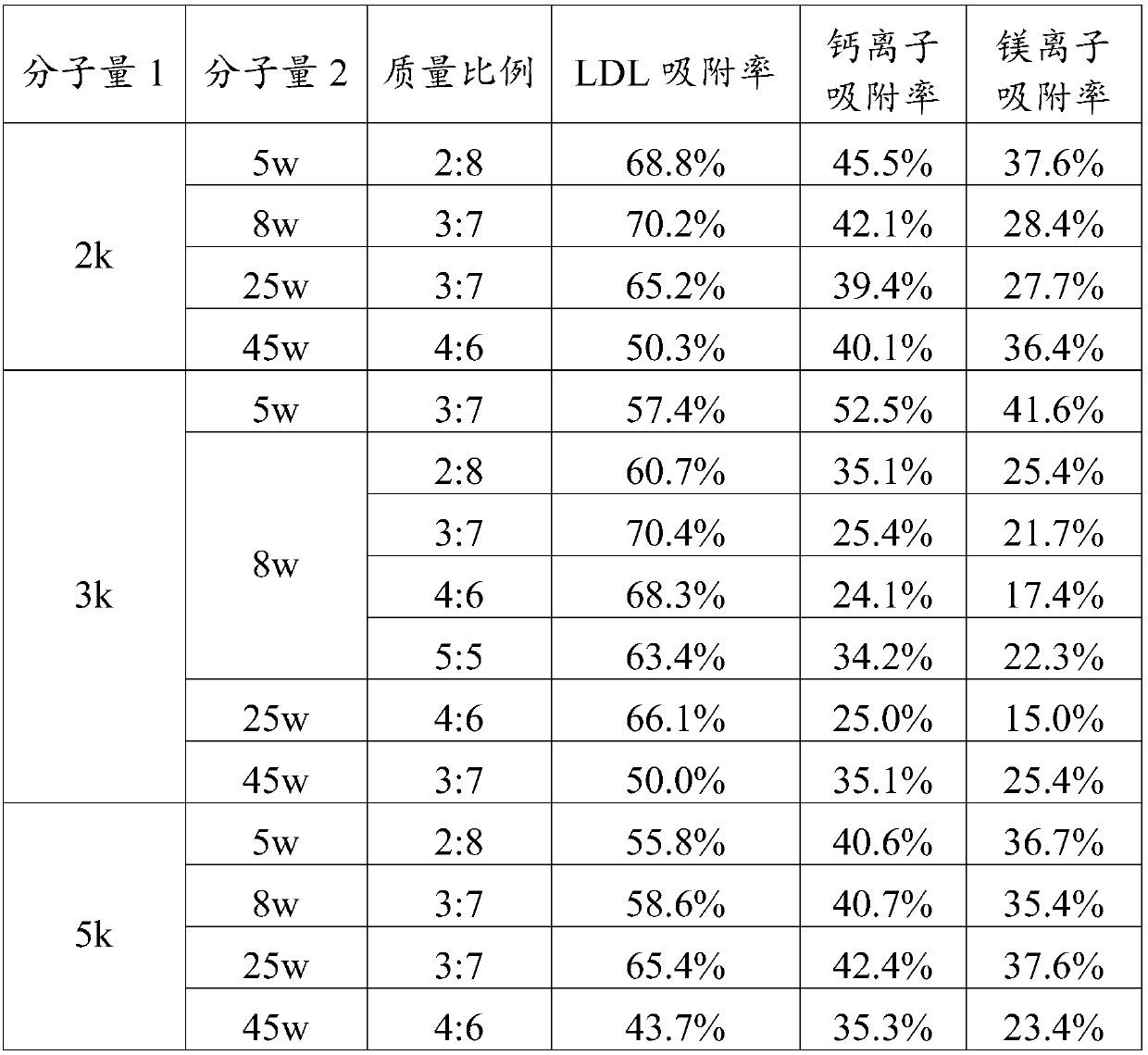

[0049] Two polyacrylic acid ligands with different molecular weights were mixed in proportion, and the adsorbent was synthesized by the method in Example 1. The adsorption rates of the obtained adsorbents for LDL and metal ions are shown in Table 2 below. The mass ratio in Table 2 refers to the mass ratio of the polyacrylic acid ligand with a molecular weight of 1 and the polyacrylic acid ligand with a molecular weight of 2 in the total mass of the ligand mixture.

[0050] Table 2 The proportion of polyacrylic acid ligand and the adsorption rate of its adsorbent

[0051]

[0052] By comparing Table 2 with Table 1, it can be seen that mixing polyacrylic acid with different molecular weights as a ligand can increase the adsorption rate of the adsorbent to LDL or maintain a high adsorption rate to LDL, while reducing the adsorption rate of the adsorbent. The adsorption rate of metal ions is even reduced by about 50%, which improves the safety of the use of the adsorbent. Thi...

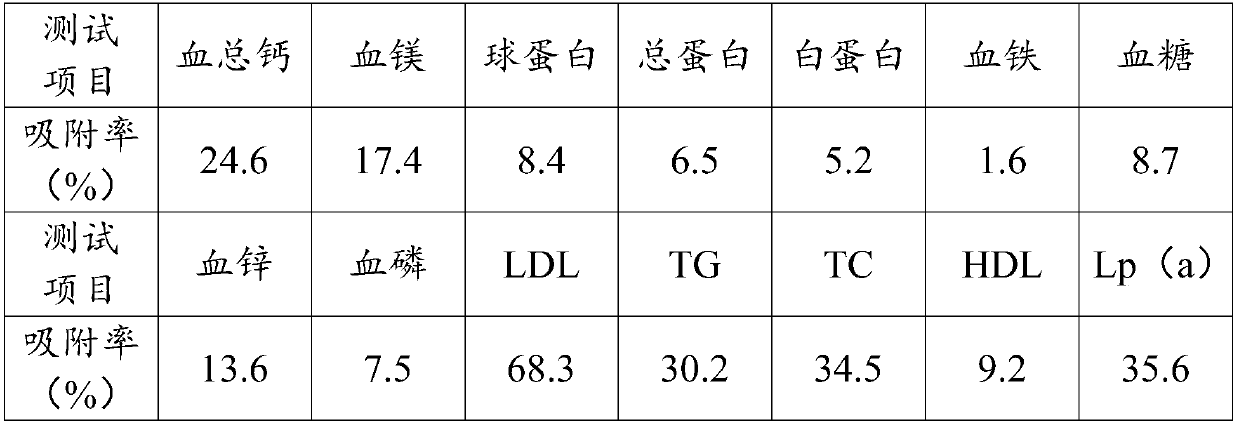

Embodiment 3

[0077] The adsorbent prepared by mixing the acrylic ligands with molecular weights of 3k and 8w at a mass ratio of 4:6 in Example 2, that is, adsorbent 2, was pre-flushed with electrolyte in a static or dynamic manner. Preflushing can be performed in two ways, static or dynamic. Among them, the step of static preflushing includes adding 1mL to 10mL of electrolyte solution to 1mL of adsorbent, sucking out the electrolyte solution completely after shaking for 10 minutes, and performing static plasma experiment on the remaining adsorbent; dynamic preflushing includes putting 100mL of adsorbent into In a cylinder with a diameter of 5 cm, use more than 50 mL of electrolyte solution to pre-flush from bottom to top at a speed of 30 mL / min. After pre-flushing, take 1 mL of adsorbent for static plasma experiments. The composition of the electrolyte solution used is shown in Table 8 below.

[0078] Table 8 Electrolyte solution

[0079]

[0080] After using different electrolytes to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com