Negative lead paste and electrolyte additives for reducing sulfation of lead-acid batteries

A lead-acid battery, negative electrode lead paste technology, applied in lead-acid batteries, battery electrodes, acid electrolytes, etc., can solve the problem of easy formation of recrystallization, and achieve the effect of preventing crystal growth, wide source, and reducing salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

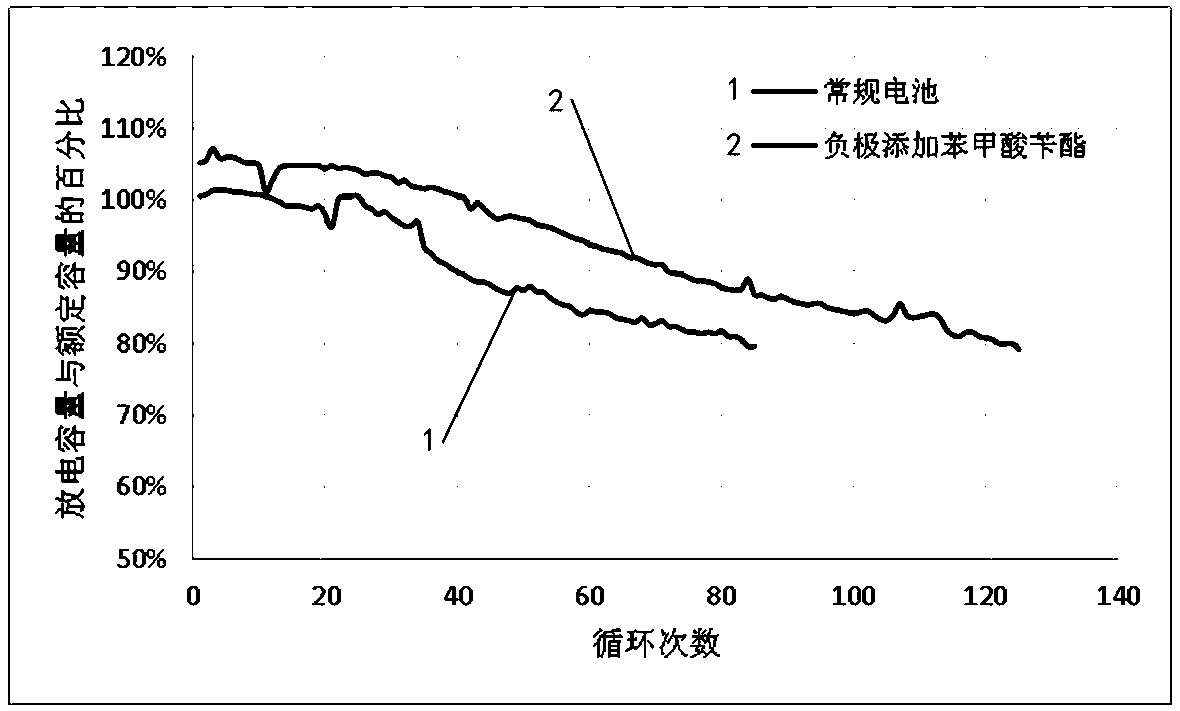

[0018] This embodiment uses conventional negative lead paste, which contains 8.5% of sulfuric acid, 8% of pure water, 0.05% of short fiber, 0.2% of carbon black, 0.4% of lignin, and 1.0% of barium sulfate measured by mass percentage. Benzyl benzoate 0.5%, the balance is lead powder. 100% DOD cycle life comparison test is carried out between the products made of this component and the products of the same specifications in the existing technology, and the specific performance curves are shown in figure 1 .

Embodiment 2

[0020] The present embodiment uses conventional negative lead paste, which contains 9% sulfuric acid, 7% pure water, 0.4% short fiber, 0.1% carbon black, 0.3% lignin, 0.8% barium sulfate, and the balance is lead powder. However, 0.5% benzyl benzoate is added to the supporting electrolyte, and the product made with this component is compared with the product of the same specification in the prior art for a 100% DOD cycle life comparison test. The specific performance curve is shown in figure 2 .

Embodiment 3

[0022] The present embodiment uses conventional negative electrode lead paste, which contains 9% of sulfuric acid, 10% of pure water, 0.7% of short fibers, 0.3% of carbon black, 0.1% of lignin, 0.2% of barium sulfate, and the balance is lead powder. , however, adding EDTA-Na 2 0.6%, the product made with this component and the product of the same specification in the existing technology are subjected to a 100% DOD cycle life comparison test, and the specific performance curve is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com