A perovskite solar cell device for modifying a hole transport layer and a preparation method thereof

A hole transport layer and solar cell technology, applied in the field of solar cells, can solve the problems of difficult control of the crystallization speed and morphology of the absorption layer, and limit the efficiency of perovskite solar cells, so as to improve carrier mobility and diffusion length , Improving charge transport efficiency and improving device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

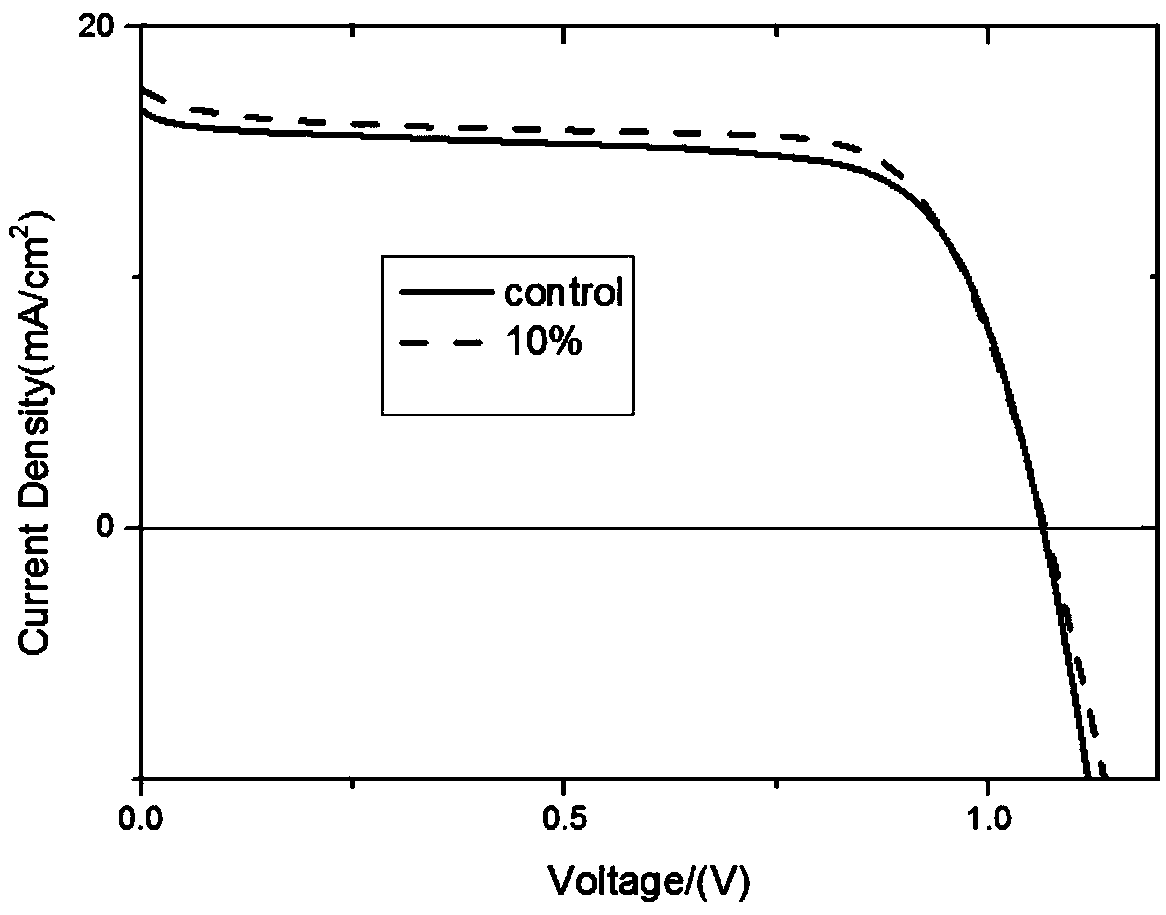

Embodiment 1

[0031] (1) Preparation of perovskite precursor solution

[0032] Weigh 222.6mg of MAI and 645.4mg of PbI respectively 2 Mix and pour into a sealed bottle, pour 700 μL of GBL and 300 μL of DMSO into the above mixture as a solvent, the molar concentration of the solution is 1.4mol / L, and let it stand in a glove box at room temperature for about 20 minutes, until the solute is completely dissolved to obtain calcium Titanium ore precursor.

[0033] (2) Preparation of perovskite solar devices

[0034] The ITO glass sheet was ultrasonically treated with acetone, deionized water, and ethanol, and then treated with plasma. PEDOT:PSS was spin-coated on the ITO glass at a rate of 4000rpm / 30s, and annealed at 130°C for 15min. Dissolve ethyl acetate in ethanol according to the volume ratio of 10%, spin-coat the modification solution on the prepared hole transport layer at a speed of 4000rpm / 30s, and dry naturally; take 35 μL of the precursor solution in step (1) and add dropwise On the...

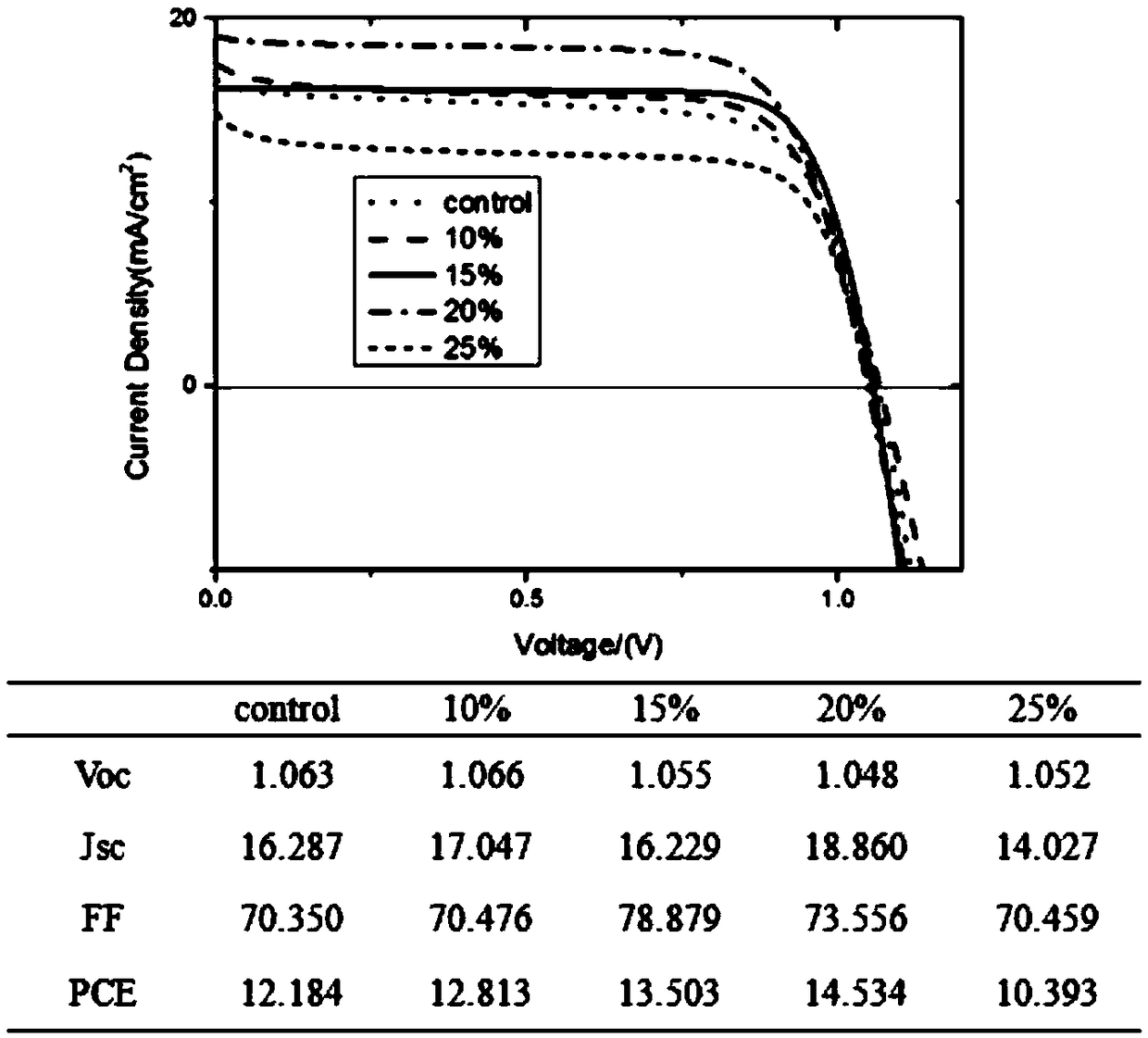

Embodiment 2

[0039] (1) Preparation of perovskite precursor solution

[0040] Weigh 222.6mg of MAI and 645.4mg of PbI respectively 2 Mix and pour into a sealed bottle, pour 700 μL of GBL and 300 μL of DMSO into the above mixture as a solvent, the molar concentration of the solution is 1.4mol / L, and let it stand in a glove box at room temperature for about 20 minutes, until the solute is completely dissolved to obtain calcium Titanium ore precursor.

[0041] (2) Preparation of perovskite solar devices

[0042] The ITO glass sheet was ultrasonically treated with acetone, deionized water, and ethanol, and then treated with plasma. PEDOT:PSS was spin-coated on the ITO glass at a rate of 4000rpm / 30s, and annealed at 130°C for 15min. Prepare modification solutions with volume ratios of ethyl acetate and ethanol of 10%, 15%, 20%, and 25%, respectively, spin-coat it on the prepared hole transport layer at a speed of 4000rpm / 30s, and dry naturally; 35 μL of the precursor solution in step (1) was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com