Distributed real-time monitoring system for manufacturing equipment

A real-time monitoring and distributed technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of data inconcentration, difficult to maintain, poor real-time performance, etc., to improve the efficiency of the solution, fast data transmission, The effect of efficient data storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical solution and technical purpose of the present invention, the present invention will be further introduced below with reference to the accompanying drawings and specific embodiments.

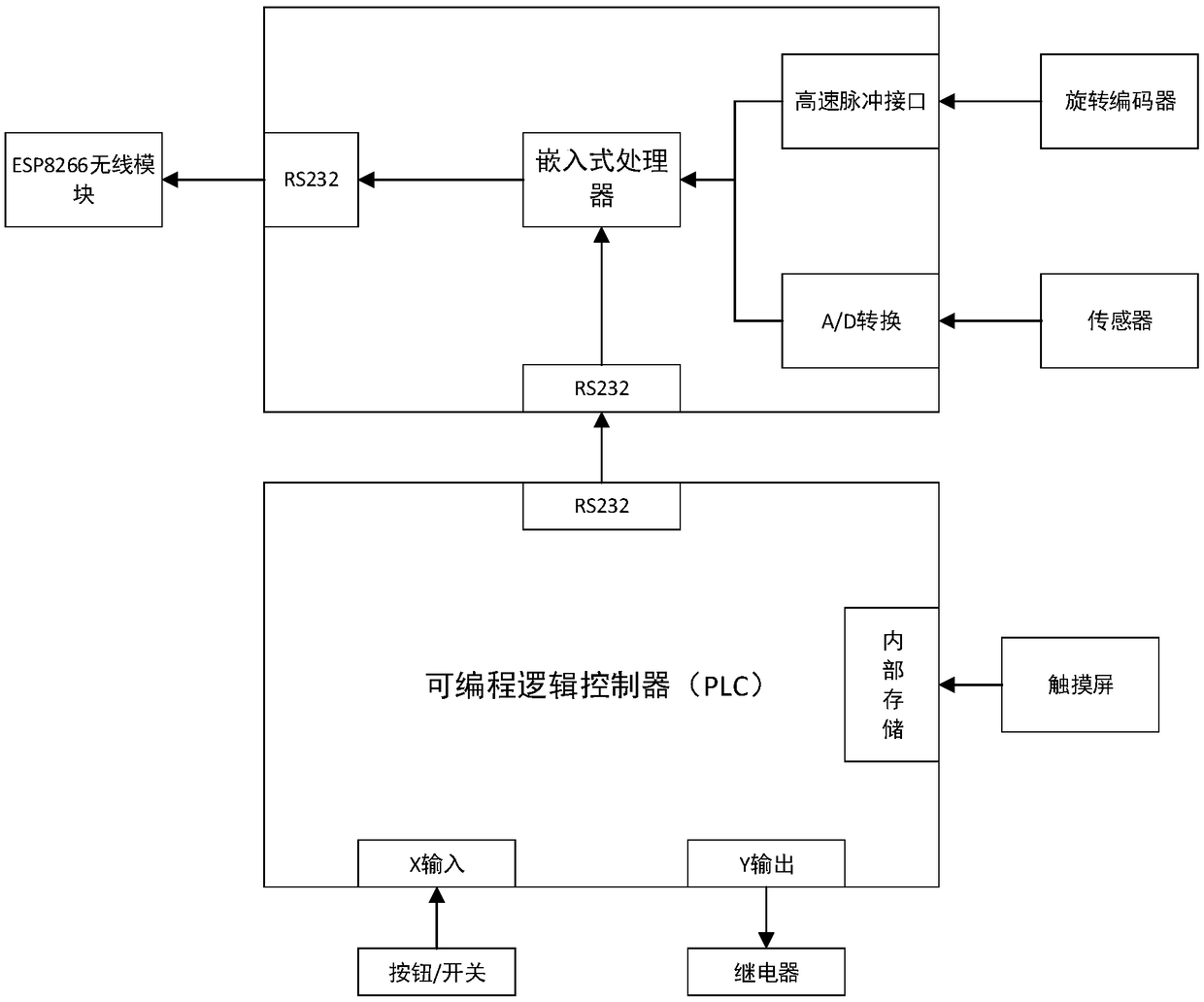

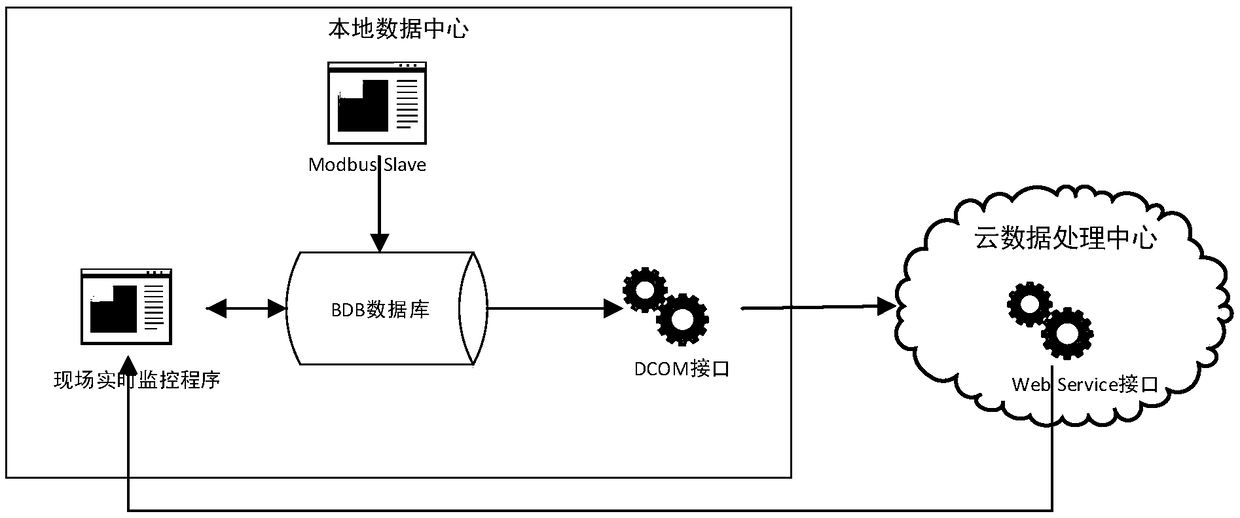

[0025] A distributed real-time monitoring system for manufacturing equipment of the present invention includes a data acquisition unit, a data processing module, a data transmission module, local servers installed in each factory, and a cloud server for querying each local server;

[0026] The data acquisition unit includes a pressure sensor, a photoelectric distance sensor, an eddy current sensor, an encoder, and a PLC;

[0027] The pressure sensor, the photoelectric distance sensor, and the eddy current sensor are respectively used to collect the pressure of the pressure-bearing parts of the manufacturing equipment, the displacement of key parts, and the moving speed of the parts.

[0028] The encoder is arranged on the electronic spindle of the equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com