Preparation method and equipment of 4-trifluoromethyl-nicotinic acid

A technology of trifluoromethylnicotinic acid and trifluoromethylnicotinic acid amide, which is applied in the field of 4-trifluoromethylnicotinic acid preparation, can solve the problems of high cost and achieve the effects of low cost, reduced reduction rate and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

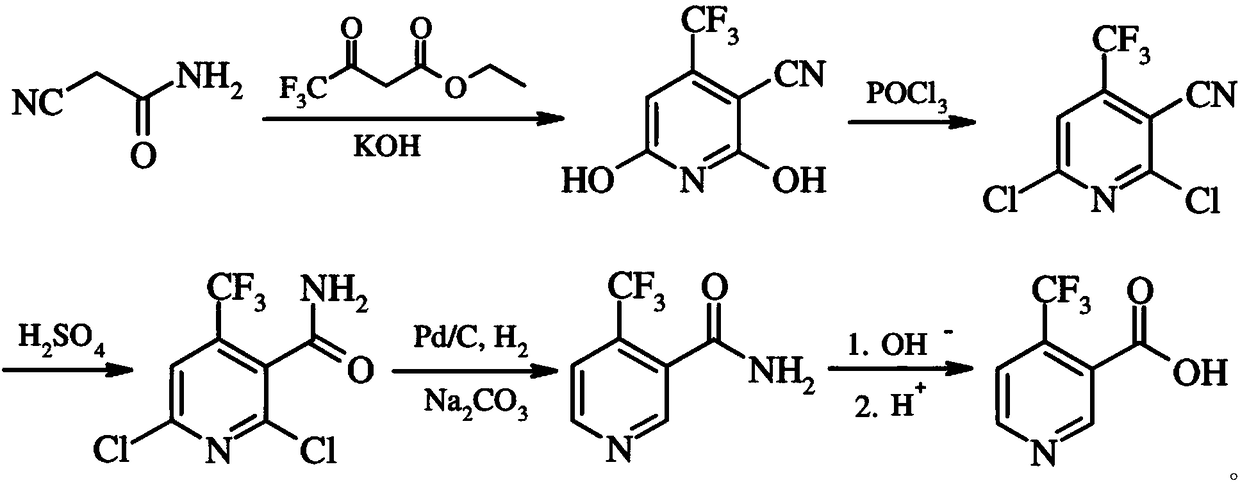

[0022] A preparation method of 4-trifluoromethyl nicotinic acid, comprising the following steps:

[0023] 1. After mixing cyanoacetamide, ethyl trifluoroacetoacetate and KOH, reflux at 75°C for 6 hours, then filter, wash and dry to obtain 2,6-dihydroxy-3-cyano-4 - trifluoromethylpyridine;

[0024] 2. Dissolve 2,6-dihydroxy-3-cyano-4-trifluoromethylpyridine in dichloroethane, then add phosphorus oxychloride and mix, then add dropwise N,N dimethylformamide, in Reflux at 125°C for 6 hours, cool, add to ice-water mixture, stir and separate layers, extract the water layer with dichloroethane, combine organic layers, dry over anhydrous sodium sulfate, filter with suction, and obtain 2,6- Dichloro-3-cyano-4-trifluoromethylpyridine;

[0025] 3. Mix 2,6-dichloro-3-cyano-4-trifluoromethylpyridine with sodium bromide, then add 80% sulfuric acid dropwise to the solution, and obtain 2,6-dichloro- 4-trifluoromethylnicotinamide;

[0026] 4. Add 2,6-dichloro-4-trifluoromethylnicotinamide ...

Embodiment 2

[0030] In step 4, feed nitrogen before high-pressure hydrogenation, carry out N 2 Replace 3-4 times to avoid leaving air in the autoclave during hydrogenation.

Embodiment 3

[0032] A preparation method of 4-trifluoromethyl nicotinic acid, comprising the following steps:

[0033] 1. After mixing cyanoacetamide, ethyl trifluoroacetoacetate and KOH, reflux at 80°C for 10 hours, then filter, wash and dry to obtain 2,6-dihydroxy-3-cyano-4 - trifluoromethylpyridine;

[0034] 2. Dissolve 2,6-dihydroxy-3-cyano-4-trifluoromethylpyridine in dichloroethane, then add phosphorus oxychloride and mix, then add dropwise N,N dimethylformamide, in Reflux at 135°C for 10 h, cool, add to ice-water mixture, stir and separate layers, extract the water layer with dichloroethane, combine organic layers, dry over anhydrous sodium sulfate, filter with suction, and obtain 2,6- Dichloro-3-cyano-4-trifluoromethylpyridine;

[0035] 3. Mix 2,6-dichloro-3-cyano-4-trifluoromethylpyridine with sodium bromide, then add 80% sulfuric acid dropwise to the solution, and obtain 2,6-dichloro- 4-trifluoromethylnicotinamide;

[0036] 4. Add 2,6-dichloro-4-trifluoromethylnicotinamide in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com