Desulfurization wastewater zero discharge treatment system and desulfurization wastewater zero discharge treatment process

A desulfurization wastewater and treatment system technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high operation and maintenance costs, large investment costs, and long process flow. Achieve the effects of fast evaporation rate, water saving and system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

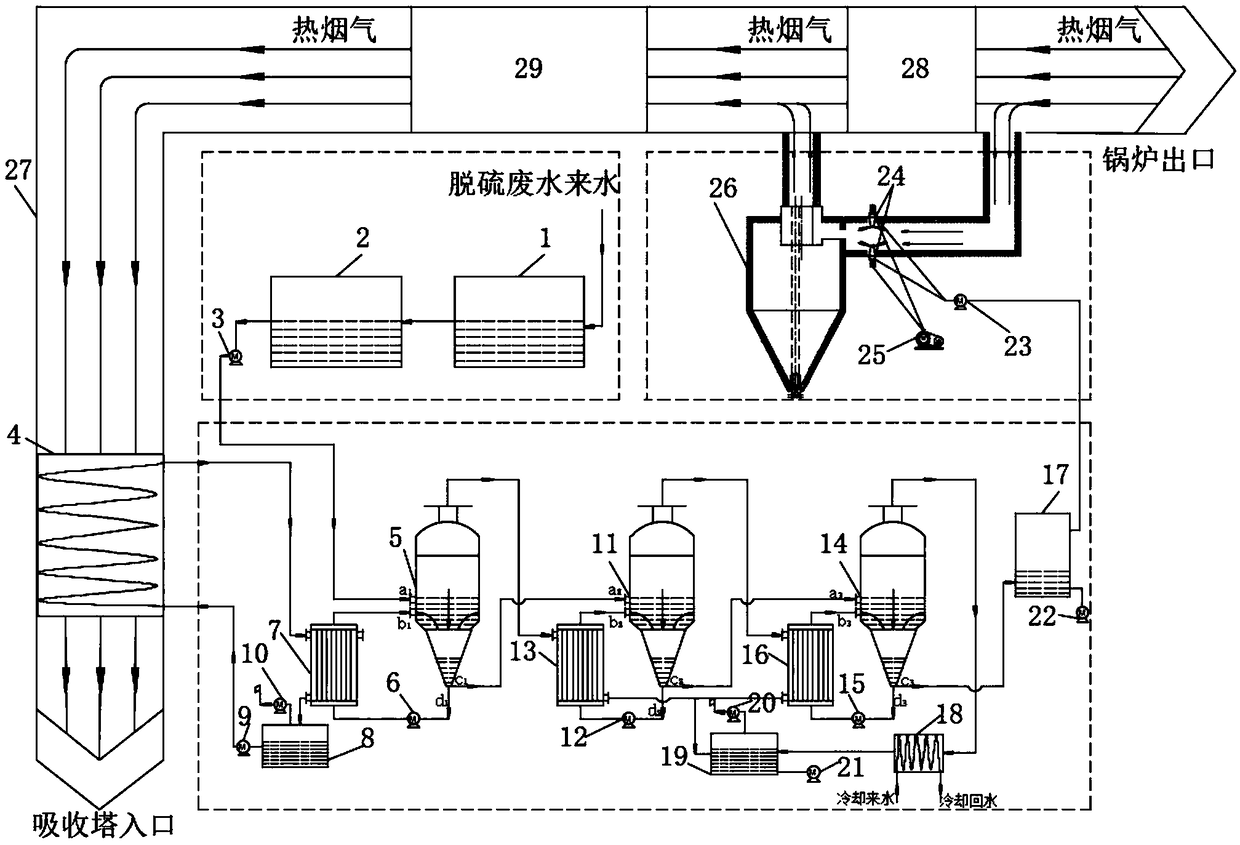

[0039] Such as figure 1As shown, a zero-discharge treatment system for desulfurization wastewater in this embodiment includes a boiler tail flue system, a pretreatment system connected in sequence, a concentration reduction system, and a high-efficiency tail liquid treatment system. The pretreatment system is used to remove Calcium and magnesium hardness and suspended solids in desulfurization wastewater, the concentration reduction system is used to concentrate and reduce the pretreated desulfurization wastewater, and the tail liquid high-efficiency treatment system is used to atomize the concentrated tail liquid evaporation;

[0040] The boiler tail flue system includes a boiler tail flue 27, an air preheater 28 and a dust collector 29 sequentially installed in the inner cavity of the boiler tail flue 27;

[0041] The pretreatment system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com