Corrosion-resistant ultra-trace metal impurity program-controlled injection pump system

A metal impurity, ultra-trace technology, applied in the field of syringe pump systems, can solve the problems of metal impurity pollution, easy to be corroded, difficult to meet strong chemical corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

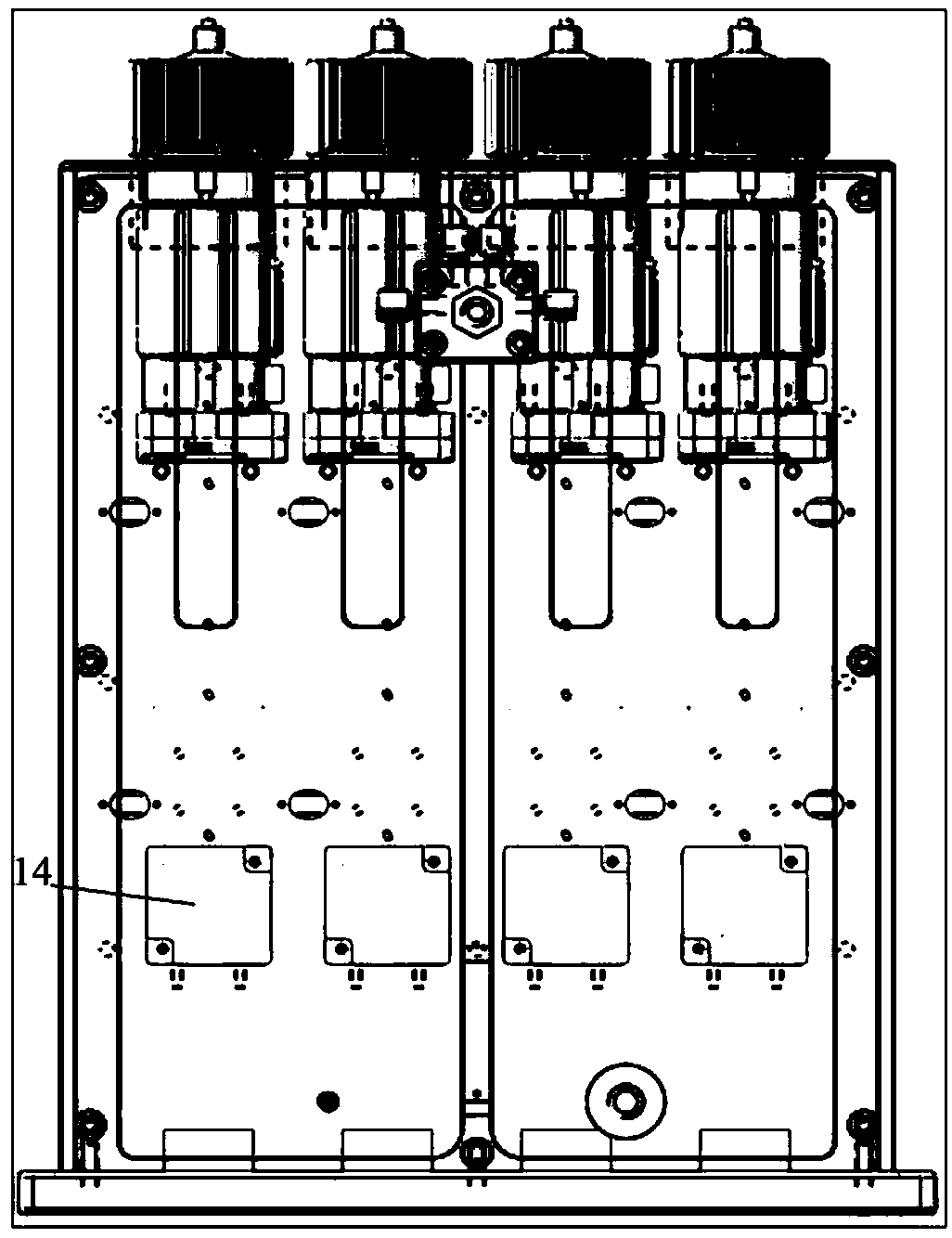

Image

Examples

Embodiment Construction

[0026] In order to better understand the content described in the present invention, the system structure and working principle of the present invention are described in detail below.

[0027] The syringe barrel 1 of the system is made of polymer materials (fluorine-containing plastics, polypropylene, etc.) that are resistant to strong chemical corrosion, and the outer side of the syringe barrel is covered with a syringe barrel fixing sleeve 2 to prevent the syringe barrel from moving up and down and the polymer material syringe barrel. deformation to ensure the accuracy of fluid injection; the syringe barrel fixing sleeve 2 is made of polymer material with high mechanical strength, and its thickness is thick to ensure its mechanical strength; the syringe barrel fixing sleeve 2 is an external thread 15 (such as Figure 2A and Figure 2B As shown), so that it can be screwed into the sealing shell 11 of the system, and when it is screwed, the outer edge of the lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com