A contact clamping force test auxiliary device for fuse type isolating switch

A technology of isolating switch and auxiliary device, applied in the direction of measuring device, instrument, force/torque/work measuring instrument, etc., can solve the problem of not easy to center, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

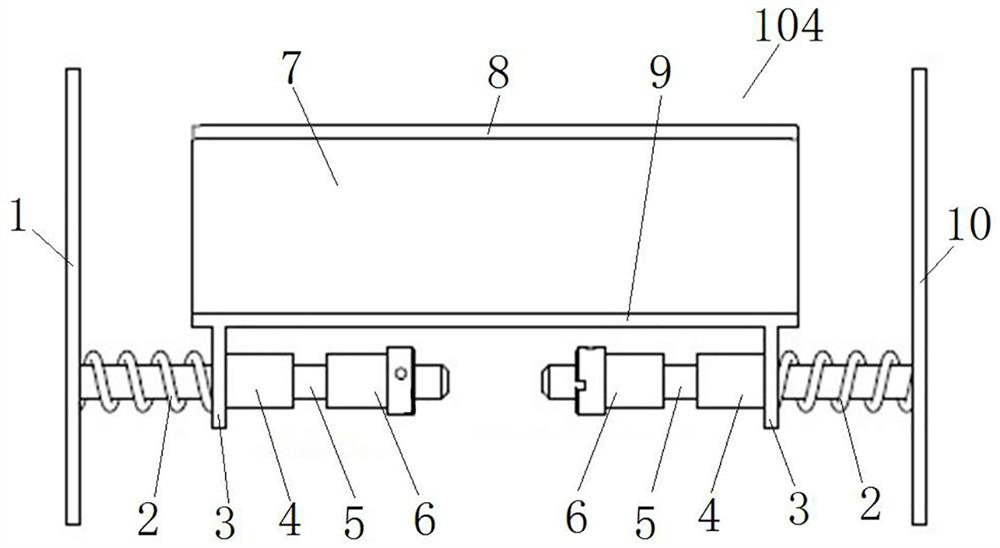

[0040] like figure 1 and figure 2 As shown, the contact clamping force test auxiliary device 104 includes a left top pressure plate 1 and a right top pressure plate 10, the left top pressure plate 1 and the right top pressure plate 10 are arranged in parallel and spaced apart, the right side of the left top pressure plate 1 and the left side of the right top pressure plate 10 Both sides are provided with support shafts 5, that is, the two support shafts 5 are arranged on opposite sides of the two top pressure plates, and the support shafts 5 are arranged perpendicular to the respective top pressure plates, wherein the two support shafts 5 are coaxial and arranged at intervals. Wherein, the opposite sides of the two top pressing plates are used to press fit with the inner side of the bending section of the handle on the cover plate.

[0041] In this embodiment, a pulling plate is provided between the left top pressing plate 1 and the right top pressing plate 10. The pulling p...

Embodiment 2

[0051] In Embodiment 1, only one compression spring is arranged between the ear plate 3 and the corresponding top pressure plate, and the specifications of the two compression springs 2 are the same, so that the pulling plate is placed on the two tops under the elastic force of the two compression springs 2. The middle position of the pressure plate, in this embodiment, a pressure spring is arranged between the ear plate and the left top pressure plate, and two pressure springs are arranged between the ear plate and the right top pressure plate. The sum of the elastic force of the compression spring is the elastic force of a compression spring between the ear plate and the left top pressure plate, so that the pulling plate is in the middle position of the two top pressure plates under the elastic force of the three compression springs.

Embodiment 3

[0053] In Embodiment 1, the plate body is a U-shaped structure, including two parallel plate segments and a connecting plate segment 7. The two parallel plate segments are provided with hook holes, and the connecting plate segment 7 is used for pushing and matching with the hand-held segment of the handle 103. , so as to drive the handle 103 to move together when the tension meter pulls the pulling plate, wherein the connecting plate segment 7 constitutes the handle pushing portion; in this embodiment, the plate body is an L-shaped structure, including a vertical plate segment and a horizontal plate segment, The horizontal plate segment is provided with hook holes, and the vertical plate segment is used to stop and cooperate with the handle, so as to drive the handle to move together when the tension meter pulls the pulling plate, wherein the vertical plate segment constitutes the handle push portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com