A glue spraying machine for semiconductor processing

A glue spraying machine and semi-conductor technology, which is applied in the direction of liquid spraying devices, paint spraying booths, spraying devices, etc., to achieve the effects of good glue spraying quality, stable glue spraying, and uniform glue spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

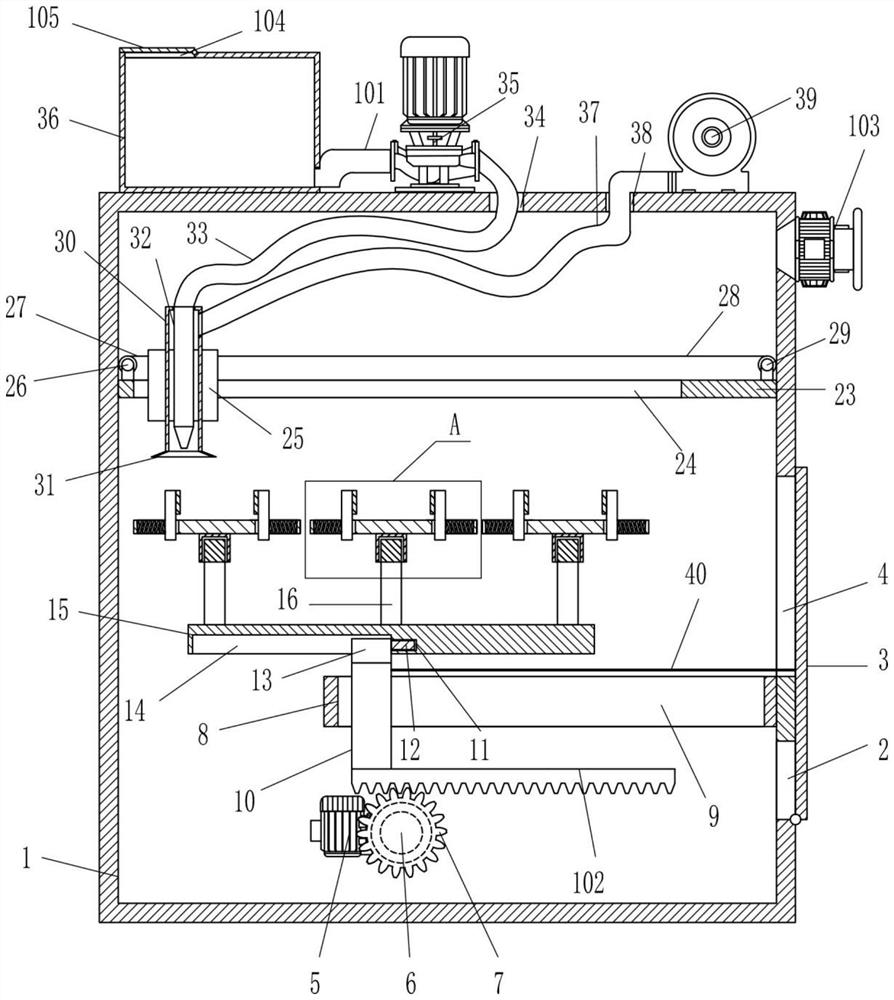

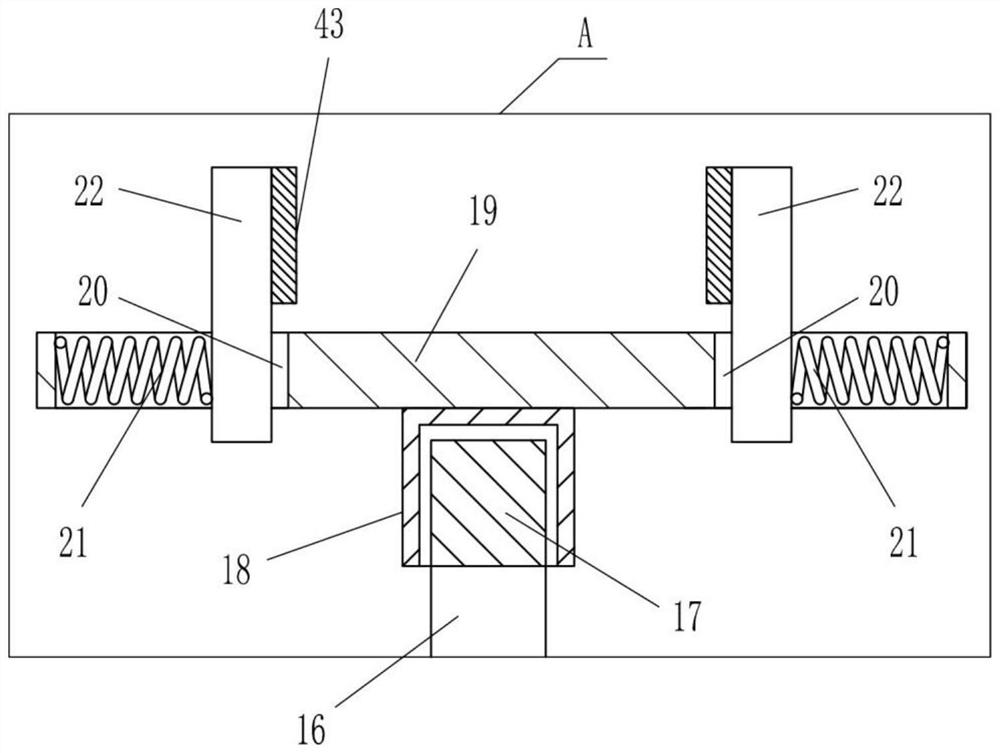

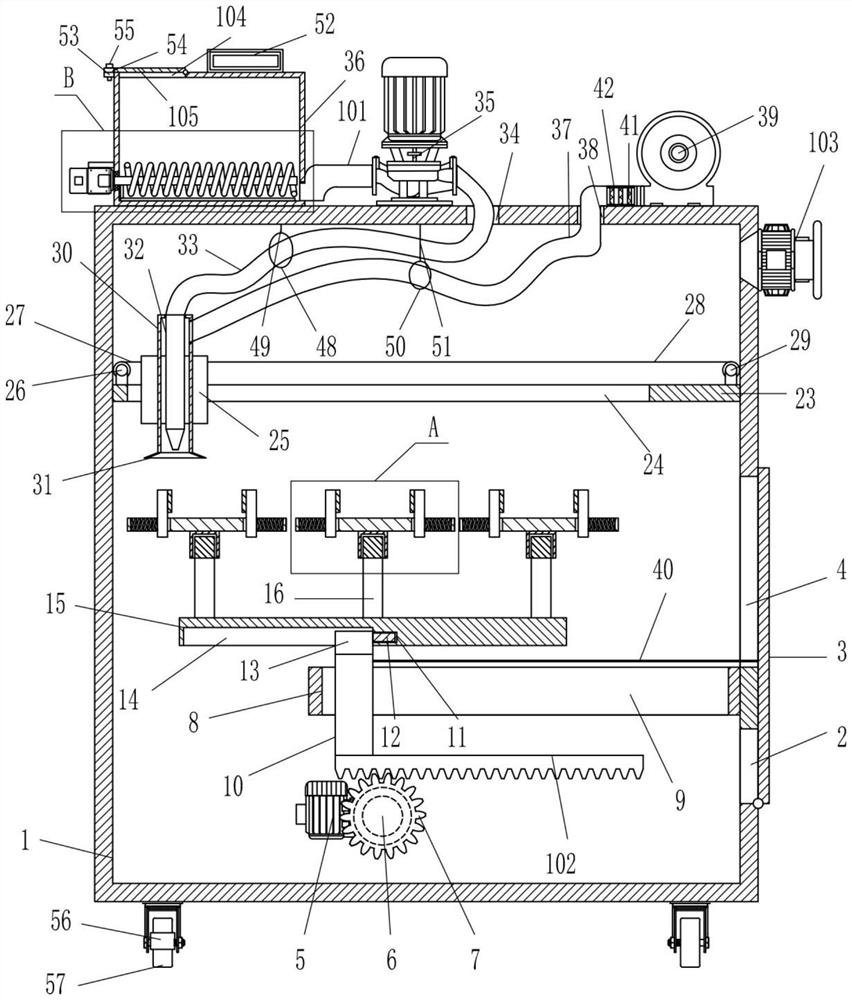

[0031] A glue sprayer for semiconductor processing, such as Figure 1-4 As shown, it includes a glue spray box 1, a sealing plate 3, a first motor 5, a first rotating shaft 6, a circular gear 7, a first mounting plate 8, a first sliding rod 10, a block 12, a first sliding block 13, The second mounting plate 15, the fixed rod 16, the fixed plate 19, the elastic member 21, the second slide bar 22, the third mounting plate 23, the second slider 25, the first electric reel 26, the first backguy 27, the second Second pull wire 28, second electric reel 29, air duct 30, wind bucket 31, glue gun 32, first hose 33, glue pump 35, glue tank 36, second hose 37, blower 39, elastic cord 40. Rubber pipe 101, rack 102 and air pump 103; the first installation plate 8 is fixed in the glue spray box 1, the first installation plate 8 is provided with the first chute 9, the first slide bar 10 and the first The chute 9 is slidingly connected, the rack 102 is fixedly connected to the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com