Full-automatic LCD glue dispenser

A glue dispensing machine, fully automatic technology, applied in the direction of cleaning method using gas flow, pretreatment surface, chemical instruments and methods, etc., can solve the problems of not being able to invest immediately, so as to improve the quality of glue application, increase the production capacity of glue dispensing, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing:

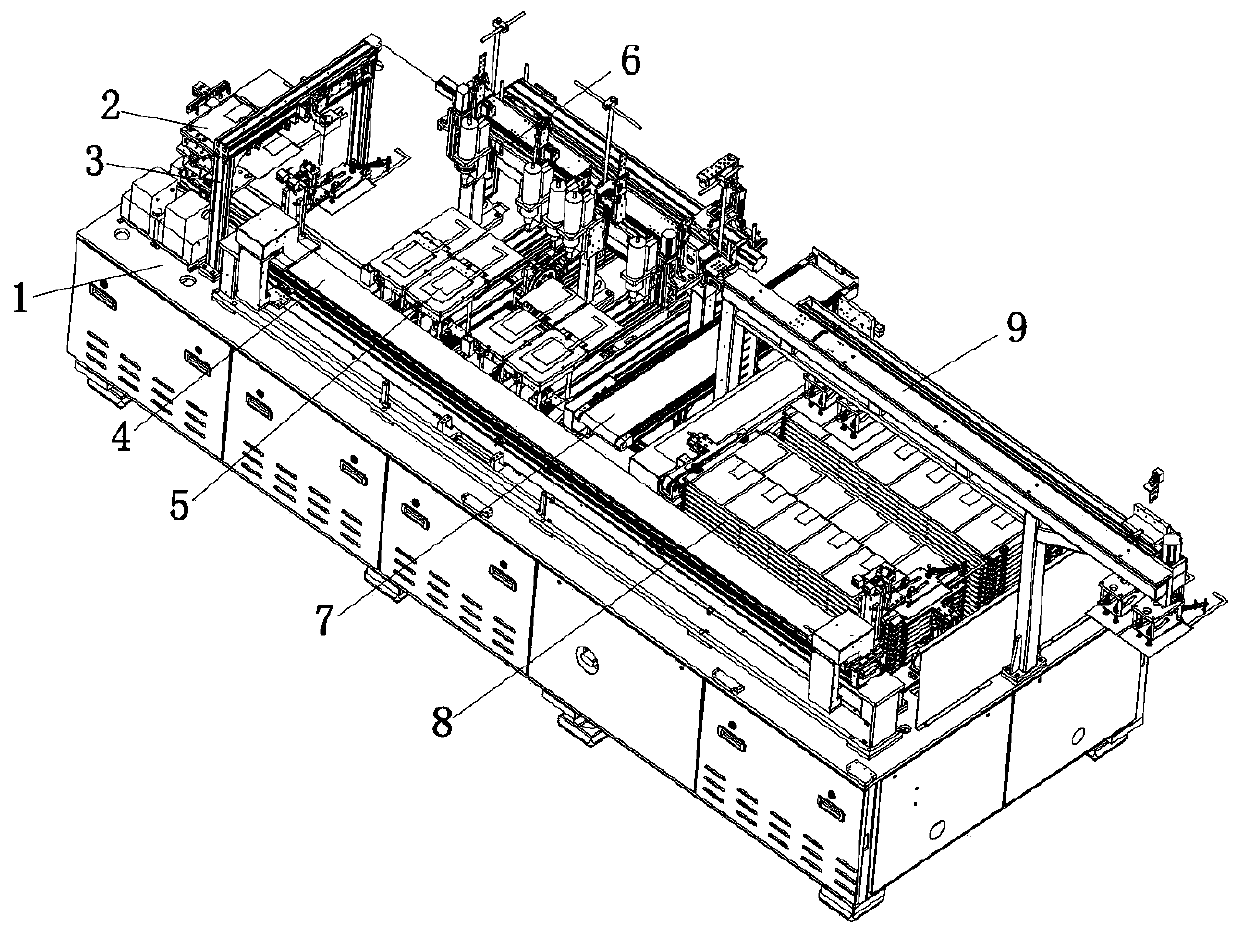

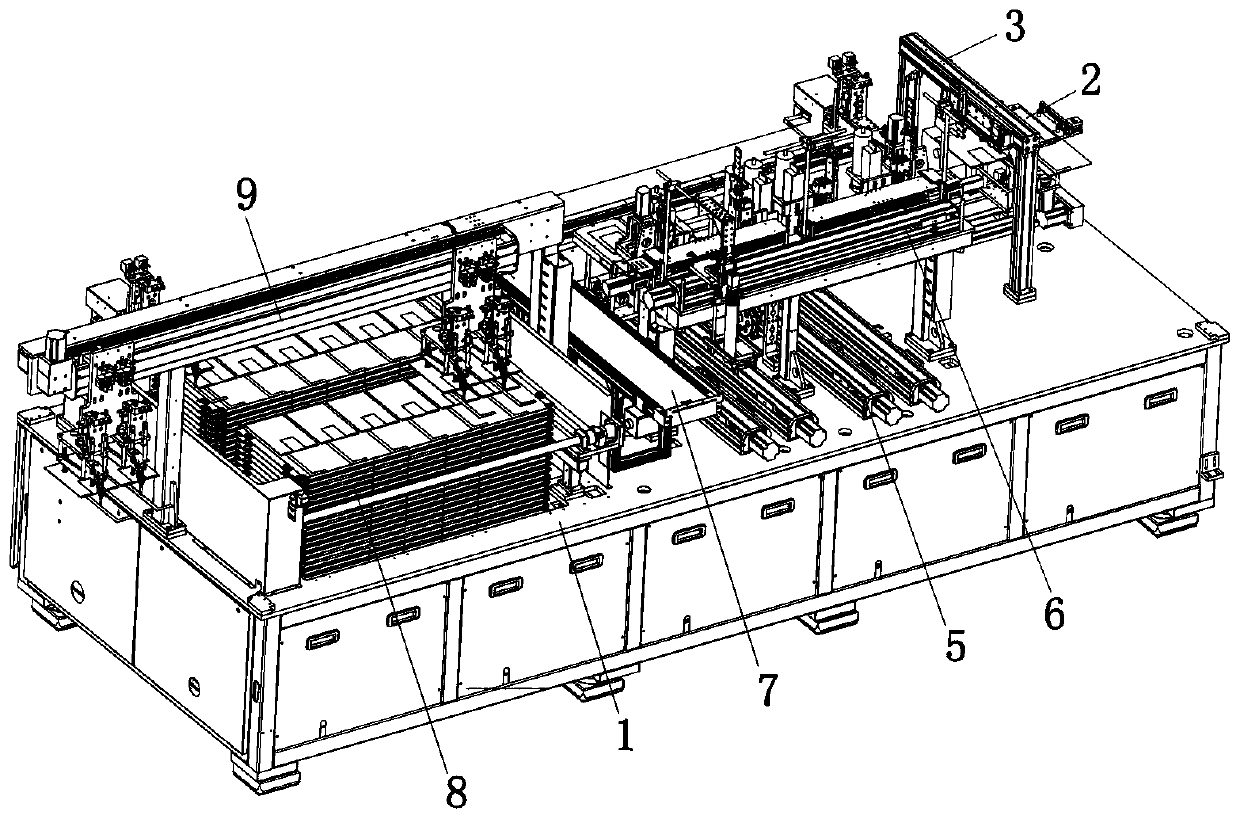

[0047] like Figure 1 to Figure 19 As shown, the technical scheme adopted by the present invention is as follows: a fully automatic LCD dispensing machine, comprising a feeding and cleaning mechanism, a feeding arm 4, a dispensing mechanism, a waste belt 7, a solidified unloading mechanism 8 and an unloading arm 9. Among them, the above-mentioned feeding and cleaning mechanism is arranged on the machine platform 1; the above-mentioned dispensing mechanism and curing and unloading mechanism 8 are respectively arranged at intervals behind the feeding and cleaning mechanism; the waste belt 7 is arranged on the dispensing mechanism and the curing and unloading mechanism. Between the mechanisms 8; the above-mentioned loading arm 4 is arranged on one side of the glue dispensing mechanism and the curing blanking mechanism 9; the unloading arm 9 straddles the top of the curing blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com