Independent rotary nozzle type compact gluing head capable of being detected online and gluing method thereof

A technology of independent rotation and gluing head, which is applied in the direction of coating, liquid coating device on the surface, etc., which can solve the problems affecting the gluing efficiency and gluing quality, large working space and power consumption, and mechanical structure occupancy, etc. , to achieve the effects of compact structure, improved scope of application, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

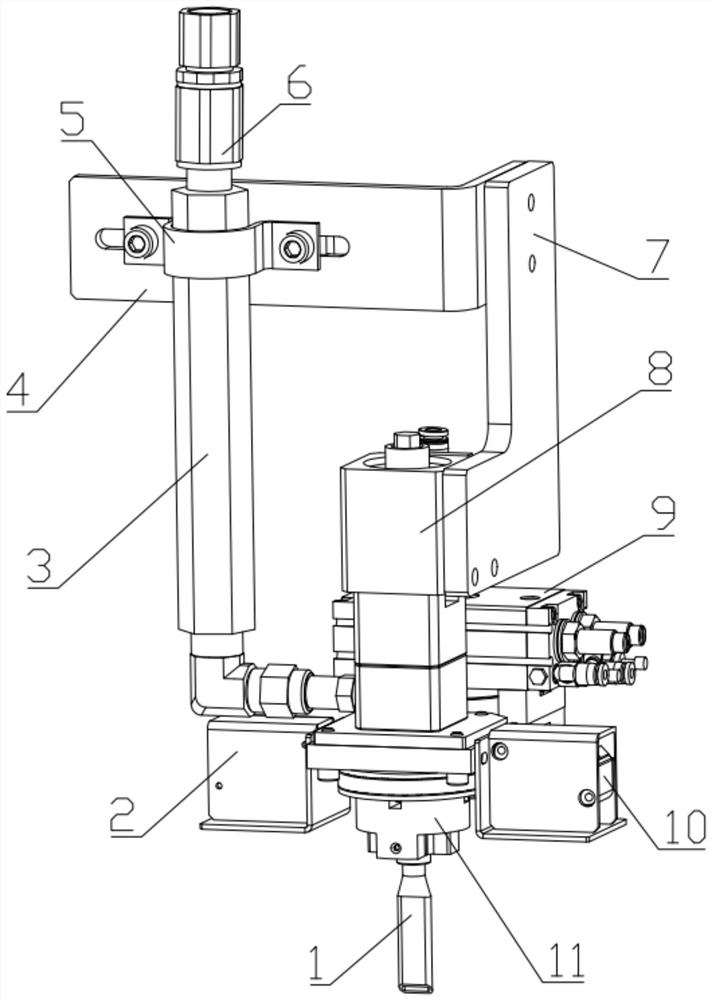

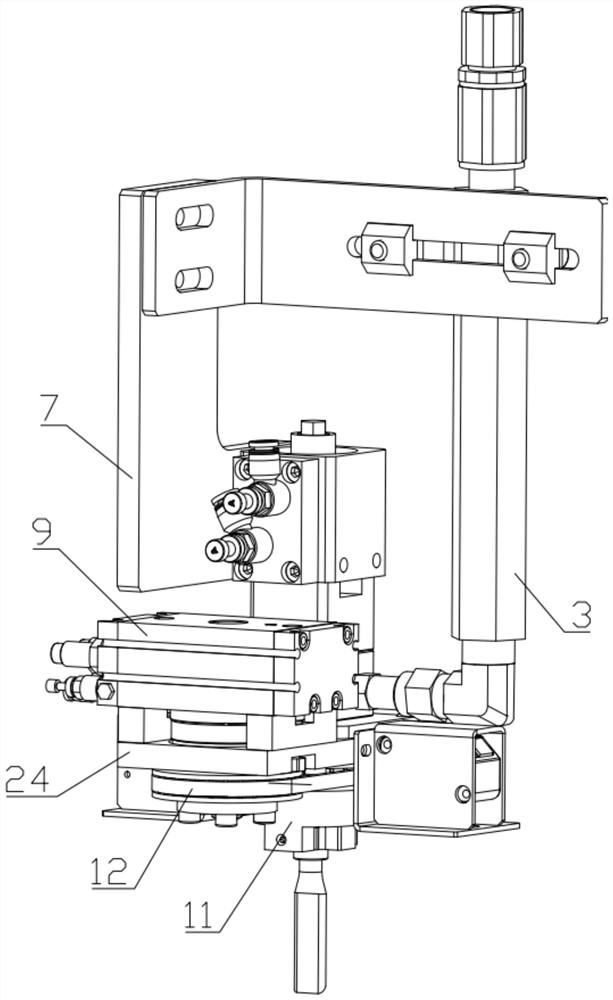

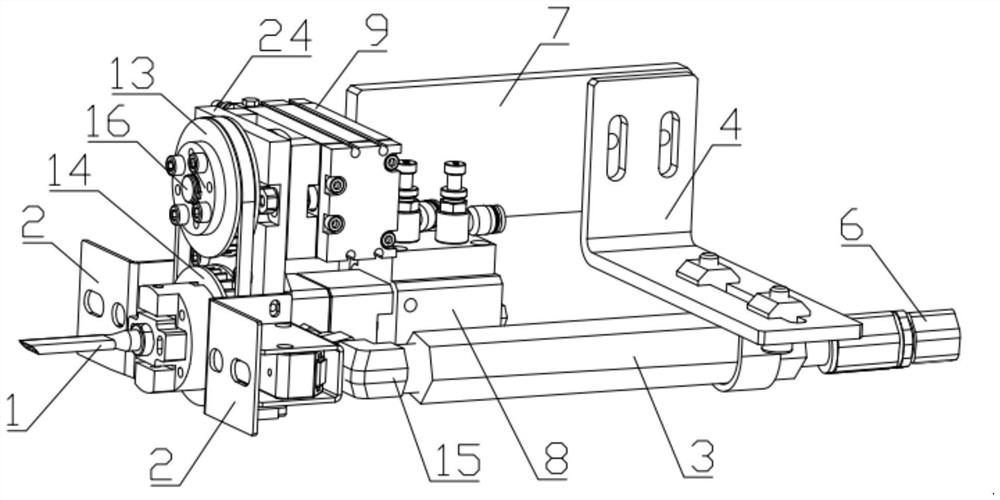

[0033] Such as figure 1 , 2 , 3, 4 and 5, the independent rotating nozzle type compact gluing head that can be detected online, including the gluing valve head connecting plate 24, the glue supplying assembly of the gluing valve, the nozzle rotating mechanism, the gluing head sealing assembly and the online Bilateral detection device. The glue supply assembly of the glue valve includes a glue valve 8 and a glue valve head 23; the shell of the glue valve 8 is connected to the glue valve head connecting plate 24 by screws; the glue valve head 23 passes through the glue valve head connecting plate 24 provides the valve head placement hole, and a shoulder on the top of the glued valve head 23 is axially limited by the top surface of the glued valve head connecting plate 24; Glue port connection; on the premise of reducing the resistance of high-viscosity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com