Automatic conveying device for gluing of veneers

An automatic conveying device and automatic conveying technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of low manual conveying efficiency, high rework rate, and high error rate, and improve the quality of veneer coating, The effect of increasing labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with accompanying drawing:

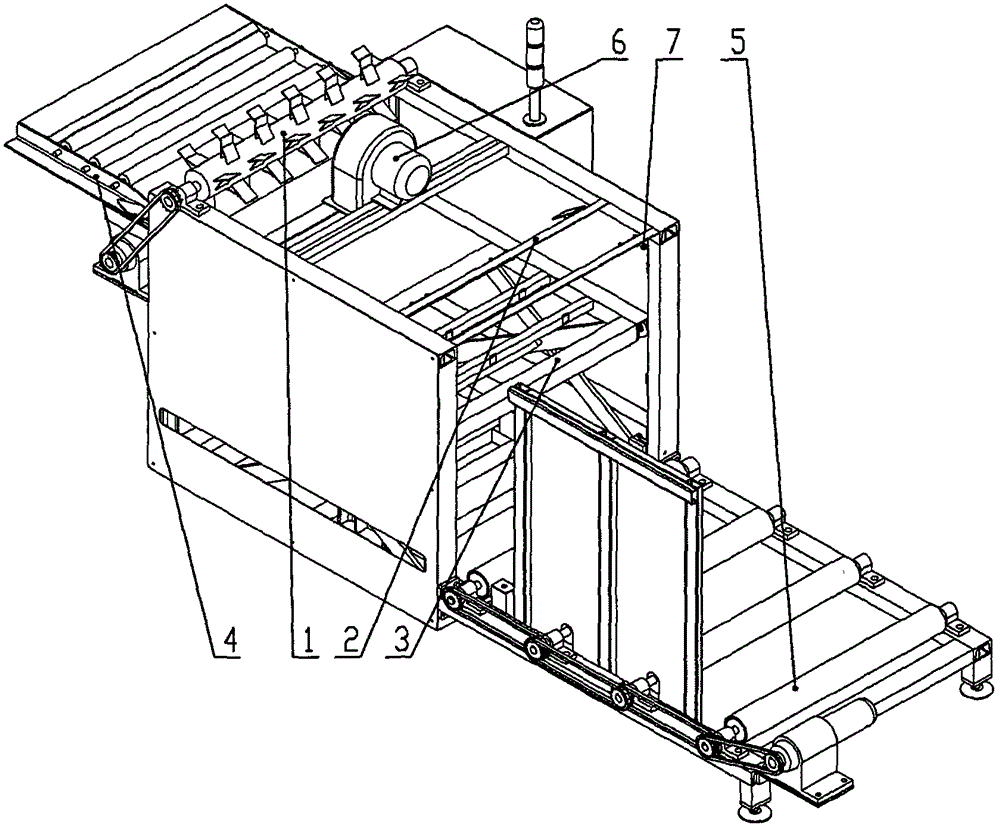

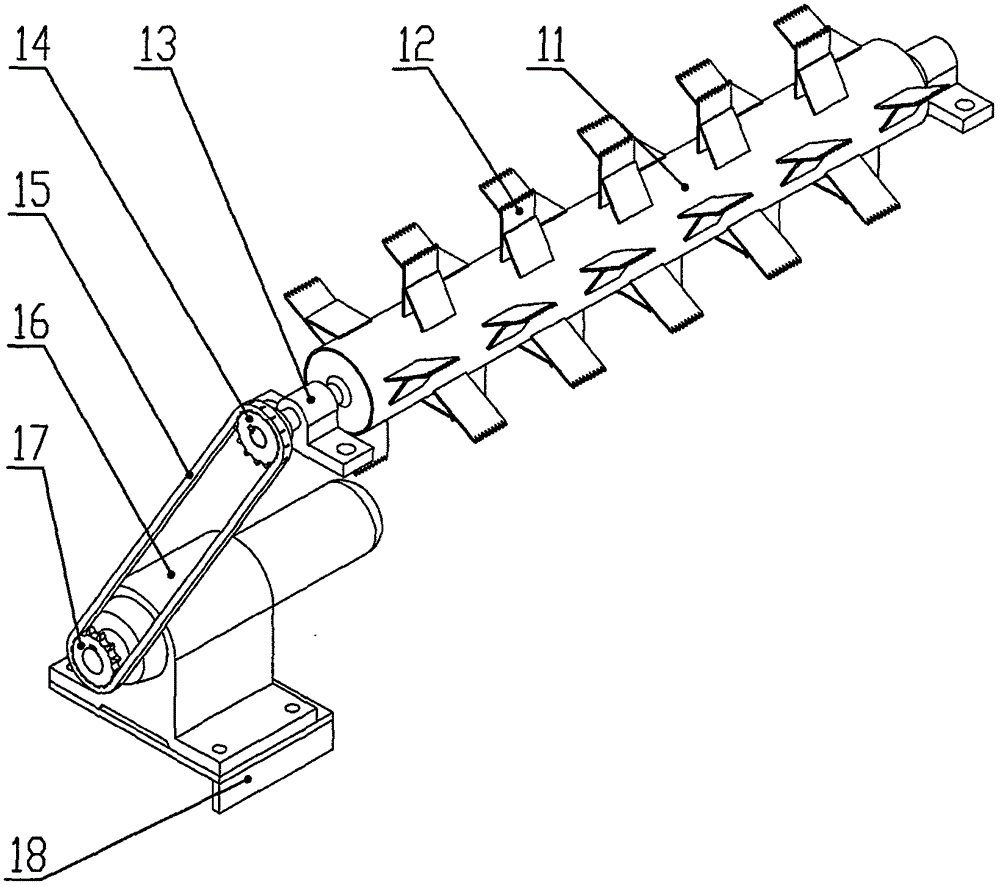

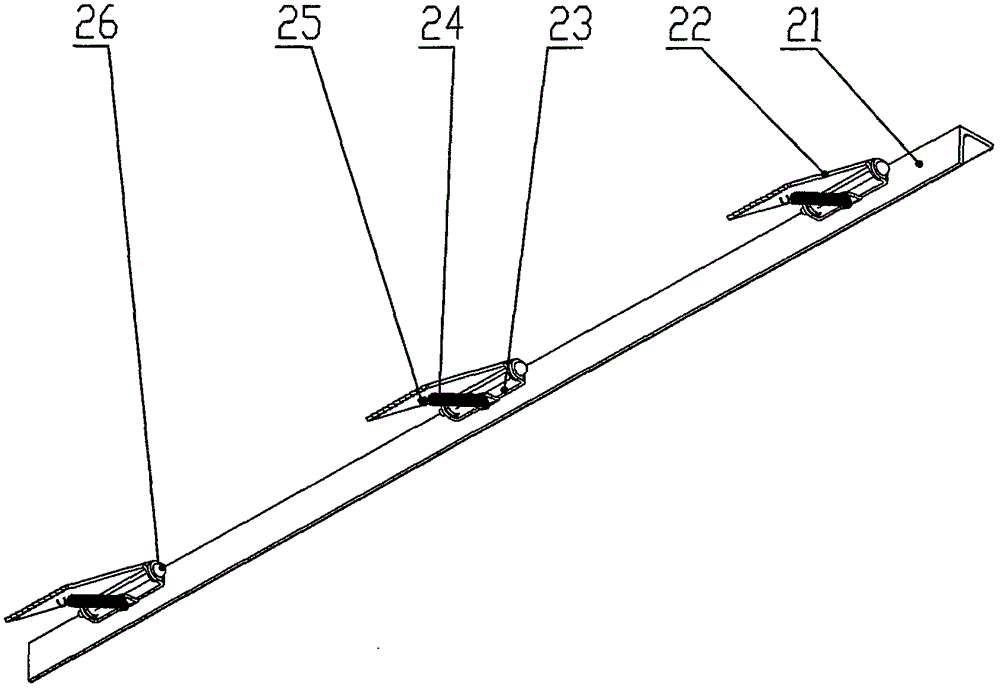

[0028] according to Figure 1 to Figure 7 As shown, the automatic conveying device for plywood veneer gluing according to the present invention includes an automatic veneer conveying mechanism 1, a reverse separation limiting mechanism 2, an automatic lifting platform 3 for material piles, a foldable directional conveying mechanism 4 with waste recycling, Material preparation and shaping conveying mechanism 5 with moisture content detection, automatic recovery mechanism 6 of impurities in the single-sheet material pile, and electrical control mechanism 7;

[0029] The veneer automatic conveying mechanism 1, the reverse separation restricting mechanism 2, the material pile automatic lifting platform 3, the foldable directional conveying mechanism with waste recycling 4, the material preparation and shaping conveying mechanism with moisture content detection 5, the veneer material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com