Monoatomic catalyst for preparation of low-carbon olefin by means of dehydrogenation of lower low-carbon hydrocarbons, and catalytic method

A low-carbon olefin and catalyst technology, applied in the direction of carbon compound catalysts, catalysts, hydrocarbons, etc., can solve the problems of large pollution, short life, high energy consumption, etc., to reduce costs and pollution, reduce metal consumption, and reduce reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

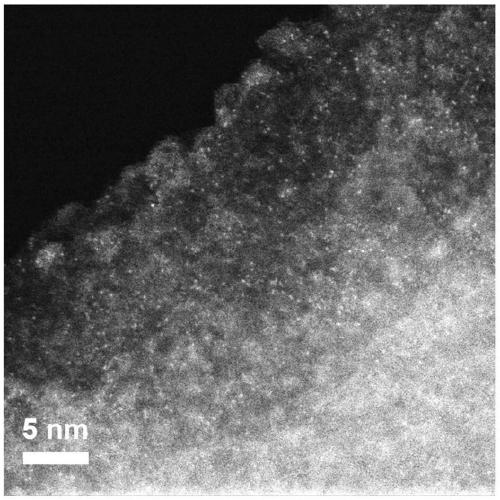

[0021] The preparation process of the catalyst of the present invention is as follows: the metal elements can be added to the corresponding metal precursors in the carrier preparation process through a one-pot method, or the carrier can be prepared first and then impregnated, precipitation, sol-gel, etc. The method loads active metal elements. The loading amount of metal elements and the composition of carrier elements can be controlled by adjusting factors such as raw material ratio, preparation temperature, preparation time and pyrolysis atmosphere.

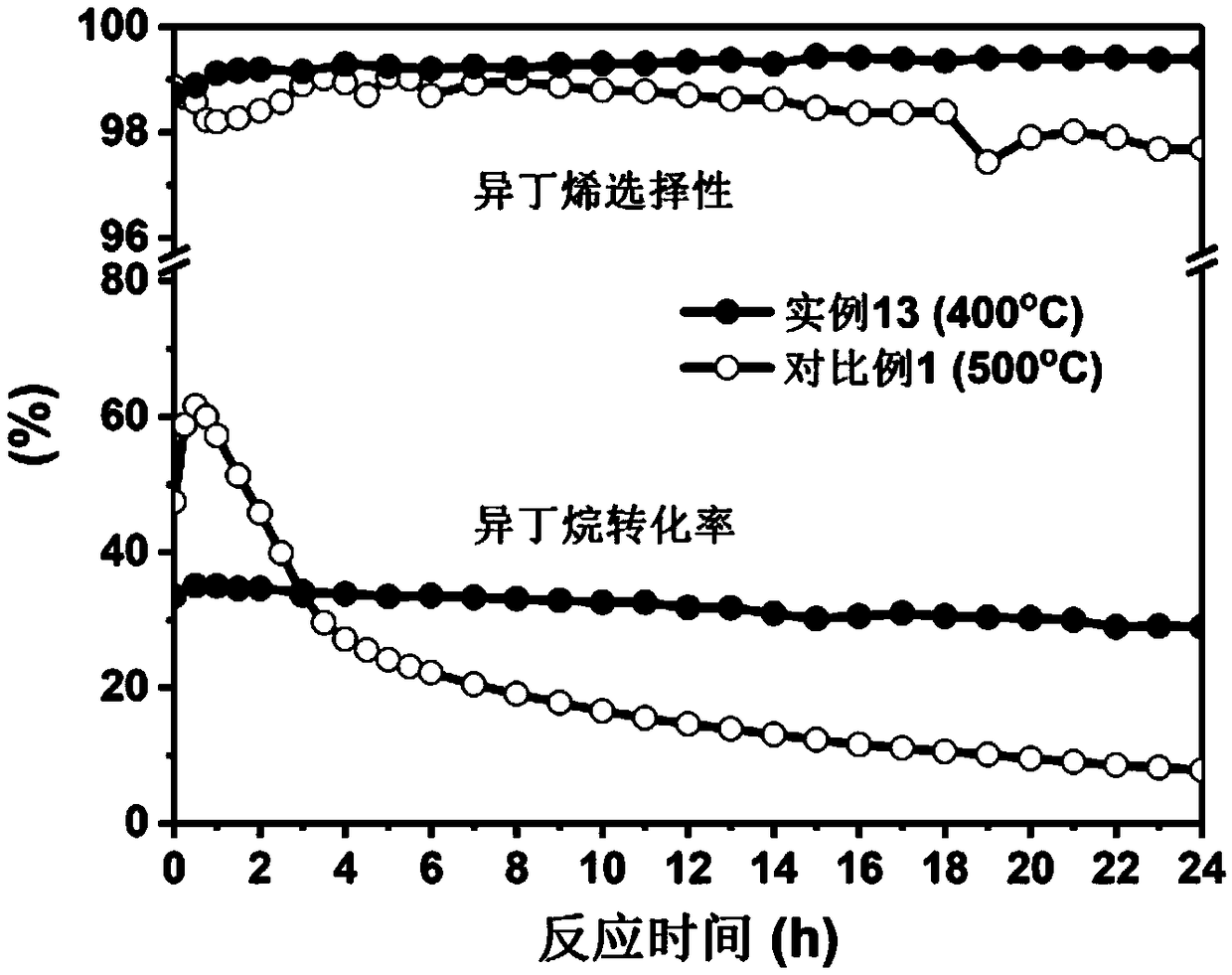

[0022] The method for testing the catalytic performance of the single-atom catalyst provided by the present invention is as follows: the catalyst can be used to catalyze the dehydrogenation reaction of a variety of low-carbon hydrocarbons (such as isobutane, n-butane, butene, propane, ethane), In order to obtain the corresponding low-carbon olefins. The catalytic reaction is carried out in the reactor, and the composition of the ...

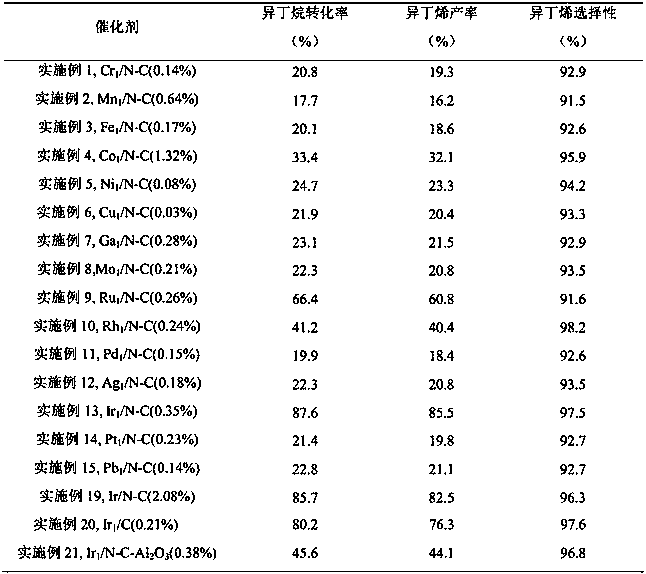

Embodiment 1

[0024] Example 1: Preparation of monoatomic chromium-supported nitrogen-doped carbon material catalyst. Dissolve 1.2mmol of chromium acetylacetonate and 12mmol of zinc nitrate in 120mL of methanol, and dissolve 72mmol of 2-methylimidazole in 120mL of methanol. After being fully dissolved, the 2-methylimidazole solution was added to the iridium acetylacetonate-zinc nitrate solution and stirred at room temperature for 24 hours. The solid product was obtained by centrifugal separation, washed with N,N'-dimethylformamide and methanol several times, dried in vacuum at 60°C for 24 hours, pyrolyzed in an argon atmosphere at 920°C for 3 hours and naturally cooled to room temperature. The monoatomic chromium-supported nitrogen-doped carbon material catalyst is prepared. After acidolysis of the catalyst, the mass loading of chromium measured by plasma emission spectroscopy (ICP-OES) is 0.14%, which is marked as Cr 1 / N-C (0.14%). Then evaluate the catalytic performance of the catalyst f...

Embodiment 2

[0025] Example 2: The monoatomic manganese-supported nitrogen-doped carbon material catalyst was prepared according to the method of Example 1, except that chromium acetylacetonate was replaced with manganese acetylacetonate. Measure the mass load of manganese and mark it as Mn 1 / N-C (0.64%); Then, the catalytic performance of the catalyst for the dehydrogenation of low-carbon hydrocarbons was evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com