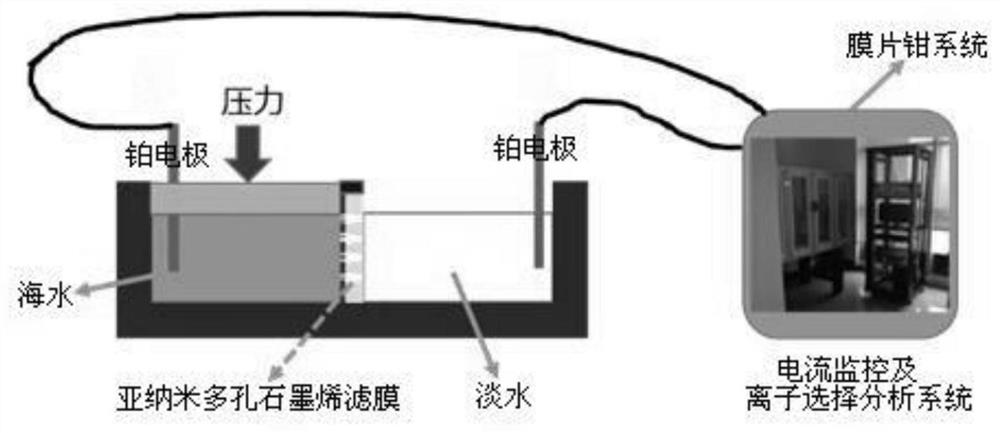

Subnanometer porous graphene permeable membrane and its preparation method and application

A porous graphene and sub-nanometer technology, applied in semi-permeable membrane separation, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc., can solve problems such as difficult to control size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

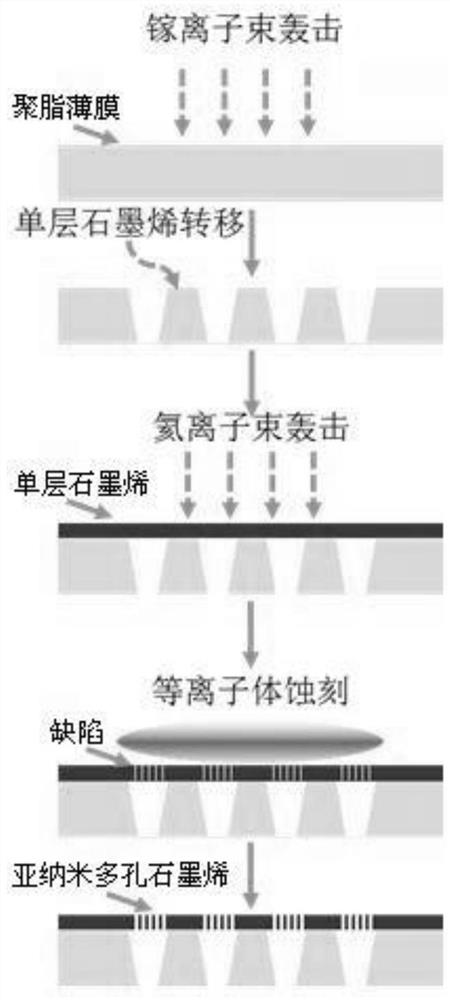

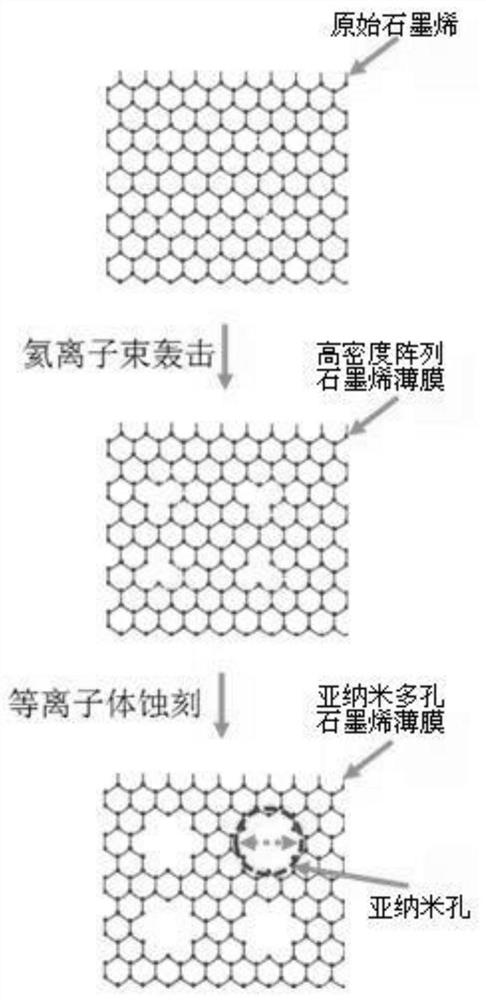

[0030] 1. Select a polyester film of 1cm x 1cm and a thickness of 0.5mm as the substrate, use deionized water to ultrasonically clean the polyester film substrate for 1min, and dry it with nitrogen to obtain the polyester film substrate for use;

[0031] 2. Use gallium as the ion source to carry out focused ion beam bombardment on the polyester film substrate, and set the working parameters as follows: select a 15 μm aperture, set the ion beam bombardment area as a circle, the diameter of the circle is 2 μm, and set the nanopore The array period is 2.5μm, the beam current is set to 0.4pA, and the dose of the focused ion beam is set to 0.07nC / μm 2 , forming a high-density nanohole array with a diameter of 2 μm on a polyester film substrate, and preparing a polyester film with a high-density nanohole array to support single-layer graphene;

[0032] 3. Transfer single-layer graphene to a polyester film with a high-density nanopore array to obtain a polyester film-based single-lay...

Embodiment 2

[0036] 1. Select a polyester film with a size of 1cm x 1cm and a thickness of 1mm as a substrate, use deionized water to ultrasonically clean the polyester film substrate for 5 minutes, and dry it with nitrogen to obtain a polyester film substrate for use;

[0037] 2. Use gallium as the ion source to carry out focused ion beam bombardment on the polyester film substrate, set the working parameters as follows: select a 15 μm aperture, set the ion beam bombardment area as a circle, the diameter of the circle is 1 μm, and set the nanopore The array period is 1.5μm, the beam current is set to 0.1pA, and the dose of the focused ion beam is set to 0.02nC / μm 2 , forming a high-density nanohole array with a diameter of 1 μm on a polyester film substrate, and preparing a polyester film with a high-density nanohole array to support single-layer graphene;

[0038] 3. Transfer single-layer graphene to a polyester film with a high-density nanopore array to obtain a polyester film-based sin...

Embodiment 3

[0042] 1. Select a 1cm x 1cm polyester film with a thickness of 0.5mm as the substrate, use deionized water to ultrasonically clean the polyester film substrate for 10 minutes, and dry it with nitrogen to obtain the polyester film substrate for use;

[0043] 2. Use gallium as the ion source to carry out focused ion beam bombardment on the polyester film substrate, and set the working parameters as follows: select a 15 μm aperture, set the ion beam bombardment area as a circle, the diameter of the circle is 2 μm, and set the nanopore The array period is 2.5μm, the beam current is set to 0.45pA, and the dose of the focused ion beam is set to 0.1nC / μm 2 , forming a high-density nanohole array with a diameter of 2 μm on a polyester film substrate, and preparing a polyester film with a high-density nanohole array to support single-layer graphene;

[0044] 3. Transfer single-layer graphene to a polyester film with a high-density nanopore array to obtain a polyester film-based single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com