Micropore filtering pipe and manufacture method thereof, and tubular micro filtering membrane and manufacture method thereof

A tubular microfiltration membrane and microporous filtration technology, applied in the field of filtration, can solve the problems of poor filtration effect, low overall strength, easy deformation, etc., and achieve the effect of prolonging the service life, improving the filtration effect, and improving the structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

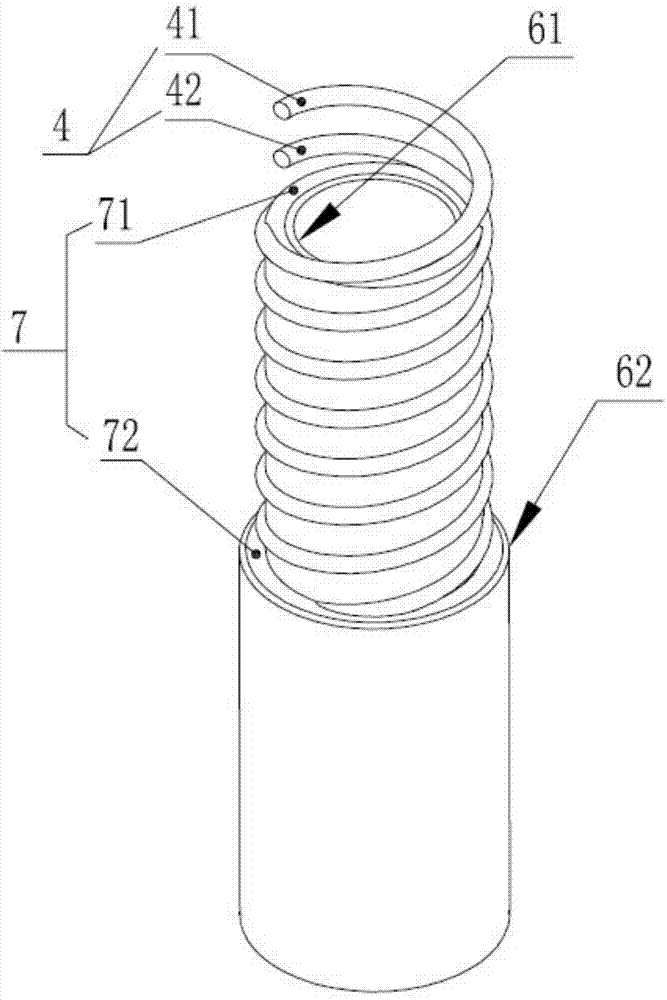

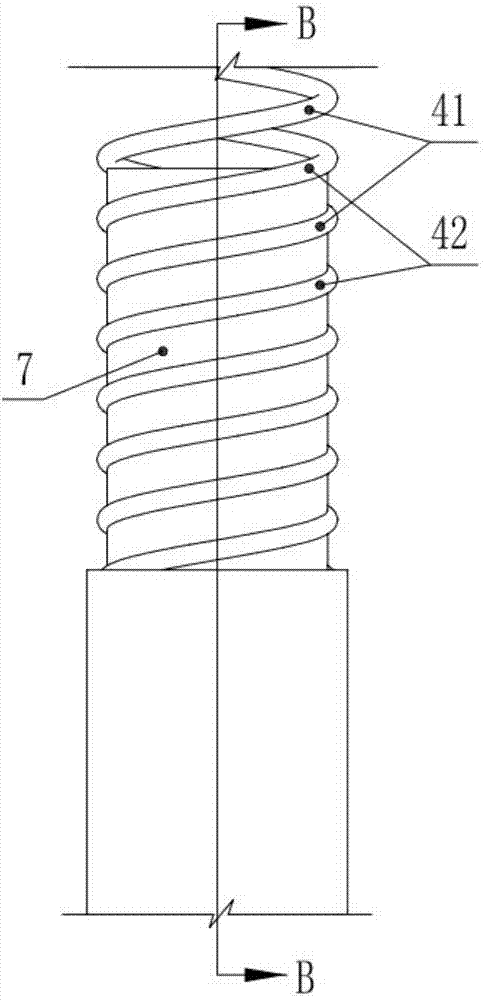

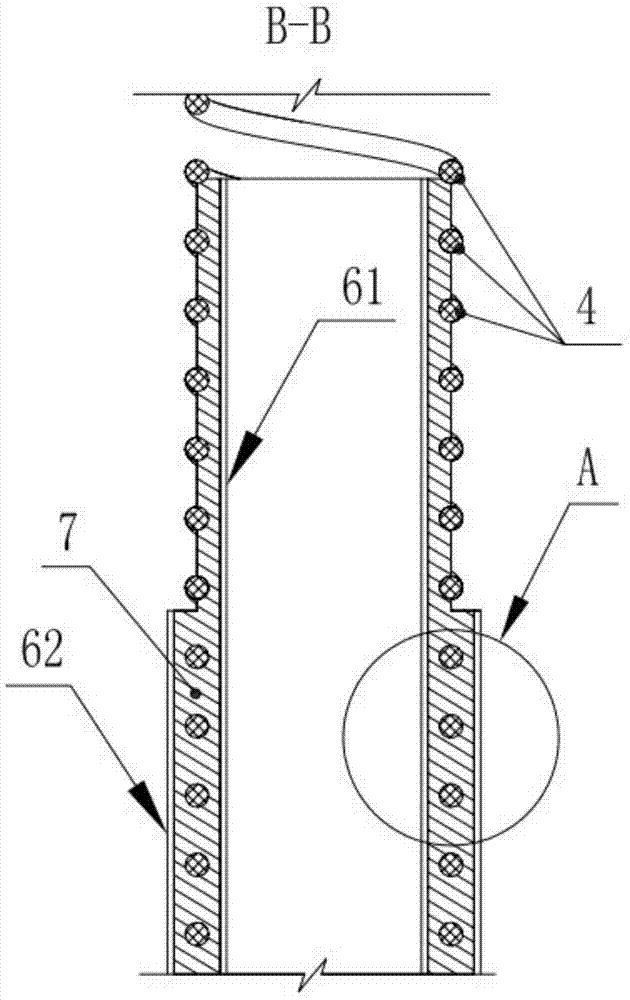

[0028] like Figure 1 to Figure 4 As shown in , the microporous filter tube of the present invention includes micropores 1 on the tube wall 7; electrode wires 4 are also arranged between the inner wall surface 2 of the tube wall and the outer wall surface 3 of the tube wall. Among them, the function of the electrode lead 4 is that when the microporous filter tube is in use, the electrode lead 4 can be connected to the power supply electrode to form a current, so that the corresponding electric field, electrophoretic migration, coagulation, electrolysis, etc. can be formed in the microporous filter tube. And many other phenomena, and due to the combined effects of the above-mentioned various phenomena, it can have a corresponding filtering effect on some special media such as electrical or magnetic particles or microorganisms. And the selective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com