Anti-static multifunctional composite punched felt

A compound needle and multi-functional technology, applied in the field of needle felt, can solve the problems of increased production cost, shortened service life of filter needle felt, poor antistatic ability of needle felt, etc., achieve long service life and improve structural strength And service life, good effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

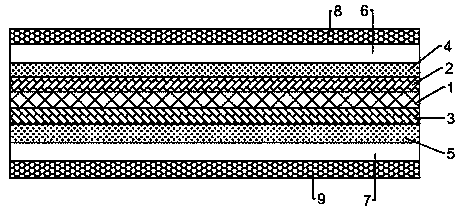

[0021] see figure 1 , in this embodiment, an antistatic multifunctional composite needle-punched felt, comprising a base fabric layer 1, the upper side of the base fabric layer 1 is provided with a first composite needle-punched felt layer 2, and the lower side of the base fabric layer 1 A second composite needle-punched felt layer 3 is provided, a first reinforcement layer 4 is provided on the upper side of the first composite needle-punched felt layer 2, and a second reinforcement layer 5 is provided on the lower side of the second composite needle-punched felt layer 3. A first protection layer 6 is provided on the upper side of the reinforcement layer 4, and a second protection layer 7 is provided on the lower side of the second reinforcement layer 5; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com