A method for preparing a crystalline silicon solar cell having a polycrystalline silicon passivation film

A solar cell and passivation film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as cost reduction and efficiency increase, and achieve the effects of reducing current density, avoiding black hole residue, and controllable reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

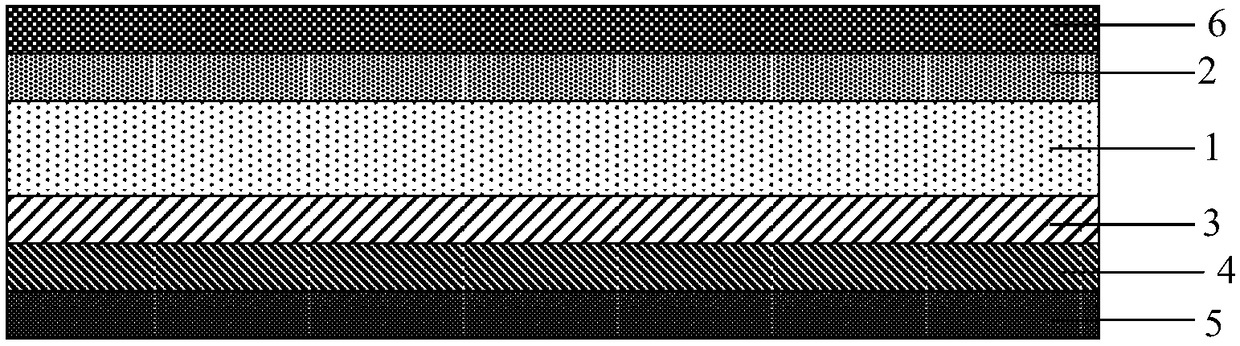

[0027] The following will combine figure 1 The preparation method of the crystalline silicon solar cell provided with the polysilicon passivation film of the present invention will be further described in detail.

[0028] The preparation method of the crystalline silicon solar cell possessing the polysilicon passivation film of the present invention comprises the following steps:

[0029] 1) Carry out double-sided polishing to the silicon wafer;

[0030] Clean the silicon wafer in a mixed alkali solution of NaOH and NaClO to remove the surface damage layer and cutting line marks, and complete double-sided polishing;

[0031] The mixed alkali solution of NaOH and NaClO, the volume ratio of NaOH and NaClO is 3:1~1:1;

[0032] This step has both cleaning and polishing processes, which saves the pre-cleaning process and improves production capacity;

[0033] 2) Put the polished silicon chip into the metal salt solution to decorate the metal particles;

[0034] Preferably, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com