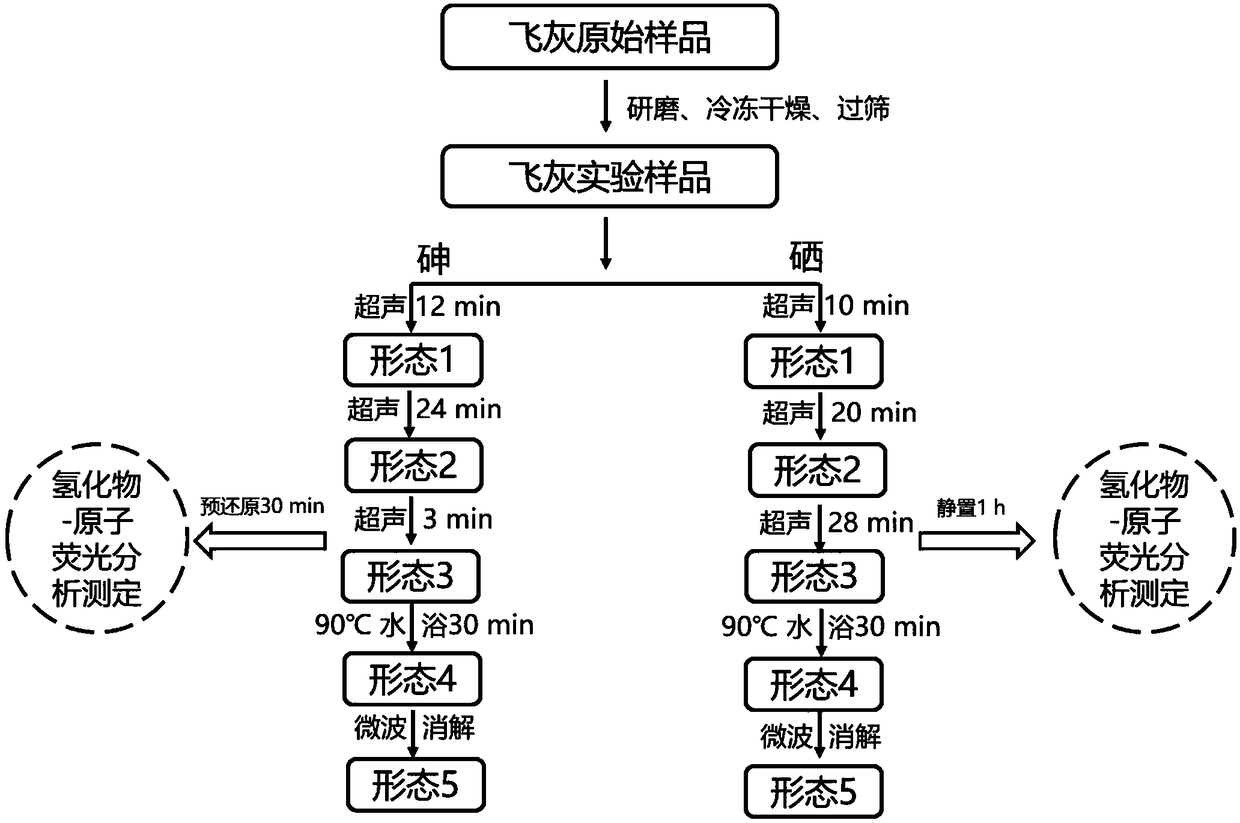

Quick extraction method for arsenic and selenium in different forms in flying ash

An extraction method and morphological technology, applied in the field of analytical chemistry, which can solve the problems of long cycle and achieve the effects of short time, good repeatability and reproducibility, and high extraction recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A fly ash sample from a power plant in Hebei was collected. After grinding, the fly ash sample was freeze-dried at low temperature for 24 hours, and then passed through a 200-mesh sieve by means of an automatic horizontal reciprocating vibrating sieving machine. The resulting sample was balanced under the conditions specified in GB / T 32722. The working parameters of the fixed ultrasonic instrument are: the working frequency is: 40kHz, the power is 250W, and the volume of the immersion liquid in the tank is 5.5L.

[0033] Extraction of non-specific adsorbed arsenic: Weigh 1g of the fly ash sample after the equilibrium treatment into a 50mL polyethylene centrifuge tube, add 25mL, 0.05M ammonium sulfate solution to fully mix the fly ash sample with the extract, and put the centrifuge tube into In a beaker containing 400 mL of ultrapure water, the beaker was placed in an ultrasonic instrument for ultrasonication. The ultrasonic was divided into 4 times. The cumulative ultrasoni...

Embodiment 2

[0040] A sample of fly ash from a power plant in Shanxi was collected, and the sample treatment was the same as in Example 1.

[0041] Extraction of non-specifically adsorbed arsenic and selenium: the extraction method and process are the same as in Example 1. The average concentration of non-specifically adsorbed arsenic and selenium (form 1) obtained by detection and analysis is 3.62±0.37 mg / kg and 2.98±0.22 mg / kg, respectively The average concentrations of non-specifically adsorbed arsenic and selenium extracted by traditional Wenzel shaking extraction were 3.91±0.62 mg / kg and 2.86±0.42 mg / kg, respectively. The average recovery rates of the ultrasonic-assisted extraction of non-specifically adsorbed arsenic and selenium with the method of the present invention are respectively 92.6% and 104.2% of the traditional shaking extraction.

[0042] Extraction of specific adsorbed arsenic and selenium: the extraction method and process are the same as in Example 1. The average concentrat...

Embodiment 3

[0048] The national standard material GBW08401 was collected as a fly ash sample, and the sample processing was the same as in Example 1.

[0049] Extraction of non-specifically adsorbed arsenic and selenium: The extraction method and process are the same as in Example 1. The average concentration of non-specifically adsorbed arsenic and selenium (form 1) obtained by detection and analysis is 4.12±0.62 mg / kg and 0.26±0.03 mg / kg, respectively The average concentrations of the non-specifically adsorbed arsenic and selenium extracted by the traditional Wenzel shaking extraction method were 4.55±0.52 mg / kg and 0.27±0.04 mg / kg, respectively. The average recovery rates of the ultrasonic-assisted extraction of non-specifically adsorbed arsenic and selenium in the method of the present invention are respectively 90.5% and 96.3% of the traditional shaking extraction.

[0050] Extraction of specific adsorption arsenic and selenium: the extraction method and process are the same as in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com